Saturday, May 12th 2012

TIM is Behind Ivy Bridge Temperatures After All

It's proven: the thermal interface material (TIM) used by Intel, inside the integrated heatspreader (IHS) of its Core "Ivy Bridge" processors are behind its higher than expected load temperatures. This assertion was first made in late-April by an Overclockers.com report, and was recently put to test by Japanese tech portal PC Watch, in which an investigator carefully removed the IHS of a Core i7-3770K processor, removed the included TIM and binding grease, and replaced them with a pair of aftermarket performance TIMs, such as OCZ Freeze and Coolaboratory Liquid Pro.

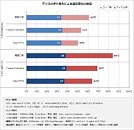

PC Watch findings show that swapping the TIM, if done right, can shave stock clock (3.5 GHz, Auto voltage) temperatures by as much as 18% (lowest temperatures by the Coolaboratory TIM), and 4.00 GHz @ 1.2V temperatures by as much as 23% (again, lowest temperatures on the Coolaboratory TIM). The change in TIM was also change the overclockability of the chip, which was then able to sustain higher core voltages to facilitate higher core clock speeds. The report concluded that Intel's decision to use thermal paste inside the IHS of its Ivy Bridge chips, instead of fluxless solder, poses a very real impact on temperatures and overclockability.

Source:

PC Watch

PC Watch findings show that swapping the TIM, if done right, can shave stock clock (3.5 GHz, Auto voltage) temperatures by as much as 18% (lowest temperatures by the Coolaboratory TIM), and 4.00 GHz @ 1.2V temperatures by as much as 23% (again, lowest temperatures on the Coolaboratory TIM). The change in TIM was also change the overclockability of the chip, which was then able to sustain higher core voltages to facilitate higher core clock speeds. The report concluded that Intel's decision to use thermal paste inside the IHS of its Ivy Bridge chips, instead of fluxless solder, poses a very real impact on temperatures and overclockability.

219 Comments on TIM is Behind Ivy Bridge Temperatures After All

*reads on*:wtf:

Err...

Hello!But I get a wall o' quoted text.

:ohwell:

If someone uses a "relatively crappy 3-4W/mk tim paste" after removing the IHS and sees temps soar it only proves that certain someone is plain stupid. Sensible person would obviously use a proper TIM such as Coollaboratory Liquid Pro (82W/(m·K)). Add to that, average IHS is slightly convex (bulging out in the middle) or even worse, concave (depression in the middle). Average heatsink/waterblock base is way more flat. Silicon chip is quuuuuite flat.

Seriously, did I really have to post this? Or are you just trolling?

:wtf:

the only part i was after was the " soldered on ihs > no ihs....

there are many more threads that have gotten ppl all exited about ihs removal only to end in disappointment.

i was going to post a thread about all of the 1366&sandybridge ihs removal success stories but.....lol

I admit removing a soldered IHS makes no sense in every case, but given the cooling system is capable of handling a bare die (like most modern waterblocks) it should be clear without-IHS > with-IHS. Air cooling of course makes little sense without-IHS as modern HSFs' extensive use of heatpipes ie. sinks' bases have pipes side by side.

www.xtremesystems.org/forums/showthread.php?280892-3770k-IHS-Removals-CPU-temp-dropped-from-79C-to-71C

...so I'm with you. What is this guy talking about IHS removal is bad?

That thread is about Ivy Bridge, whose IHS is not soldered.

all ive been going on about is USING the ihs with new paste...which is getting great results...if you spent that much time looking around xs than you've seen first hand what im talking about

Anyway, I voted No, they dont need to change anything. I dont give a hoot about the warm temps b/c Im not overclocking the 3770k past 4-4.2Ghz which the H100 and just about any air cooler can handle. Its when you push further than that, usually around 4.5ghz that things start to ramp up. hen I push past 5-6Ghz, I will be on Dry Ice/LN2 anyway so I do give a hoot. :)

ive not delidded a cpu ever(not poss on the cpu's ive had) but you clearly are doing something wrong if it ends up hotter, as that makes no sense at all , if you have a waterblock direct on a chip it will convect just as efficiently as the IHS but there will be less thermal insulation between the heat source and the cooling surface/water ,so it will in effect cool quicker/ better stronger longer.

sorry...thats just not how it works. one of the most important thing with thermodynamics is surface area....

and what i posted was not something i did,,, as i said in said post it was a copy/paste from xtremesystems....

but yes....lapping does help emensly....rare are flat ihs's....i take mine all the way down to 2000wg on a flatbench.....ive wanted to have one decked slightly but i dont trust my machine shop that much

your still wrong , AN IHS has very very marginaly (just the edges around) more contact, then a waterblock direct fitted but without the IHS you have two less thermal barriers that insulate the processor to some degree (IHS and chip>IHS tim) , the laws of thermodynamics are on my side here mate, and said waterblock removes heat from the copper block faster leaving the block and chip at a lower temp or a higher OC, unless that is, YOU fitted it:p

how on gods green planet are you finding enough additional surface area that this magic IHS of yours is in contact with, if i were to fit a block to a chips core direct, id use the best non conductive gel strip cut around the chip(correct depth obv) onto the interface pcb(which would do very little but you gota try, then a skim of the best(not blob) tim i could find /buy so yes the chips very tiny edge wall would not be in contact but , why the, im out your clearly jus trollin

and in the end the best you can do is to call troll....nice

so if ihs is soooo egregious tell me prey-tell why intel and amd spend extra manufacturing dollars on them in the first place???

essentially they became neccessary when we all started building and messing with our pc's and what chip do people mess with most;) .

oh and im not arguin that anyone should do this just that your wrong:p

Ya know there is really no point to arguing about this anymore, this is just like beating a dead horse. Intel had their reasons to do it. If you really want anything to change, stop the damn bitching here and write a Letter to Intel R&D, Engineering, Marketing, CEO.

And FYI the IHS was purely only designed so dumb people dont crush the cores of CPUs.

-End Rant Unsubscribed!-

You need to do more research pal. The only people that see higher temps with a removed IHS are those that installed their block or cooler improperly or suffer from poor cooler to die contact (which can be due to incompatible heatsink/block design, or user error).

Every single chip I ever delidded saw better temps without the IHS. I even lost 5C under load on a 6400+ with a measly Freezer 64 Pro, which had a soldered IHS.

the IHS is purely there to prevent damage to the CPU, its not there to help temps.

Most (if not all) laptop processors don't have IHSs to yield more effective cooling with limited amounts of space designated for the heatsink. If IHSs helped temperatures, Intel/AMD would include them, especially when thermal efficiency is an imperative part of laptops.

Maybe there have been complaints.

If there is a revision on the IHS to make the K series soldered at least I am sure my Brother will be selling his 3770K....

None the less he is getting 20+degC idle temps using an H60.

hasn't mentioned anything about the max temp but then again he feels he doesn't need to check until he starts to OC.

Your ghetto typing doesn't give your posts much credibility.

now were up to putting a giant piece of metal on the chip so the unsteady-handed dont break their new toy.... wow....

last one then i'll give up i apologise for not being smart enough convince you guys of the truth.

IF its only there to prevent damage and does NOTHING thermally....why does AMD put a FULL and rather larger IHS on their cpu's. but only uses a shim arround their (cooler) gpu chip???

same with Nvidia???

anyone...

Also because video cards simply cant spare the cooling capacity - unlike CPU's, they cant afford a 5-10C heat increase.

this forum is not easy to troll. please stop wasting your time.

i know you're a modderator but lmgtfy.com/?q=troll

this is on topic and fairly unemotional.....

not a troll

oh well i suppose you can lead a horse to watter