pvillegeek

New Member

- Joined

- May 16, 2010

- Messages

- 1 (0.00/day)

Better late than never

It looks like I'm a little late to this party, but seeing your schematic made be cringe!

I guess I should start off by mentioning that I am an electrical engineer, so I know what I'm talking about.

What's right:

On the positive side, you did keep ground as ground, and you chopped the 12v line (I've seen several attempts messing this up). If you chop the ground wire it will mess up the tach output. Other than that I'm surprised this circuit works at all.

What's wrong:

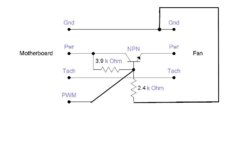

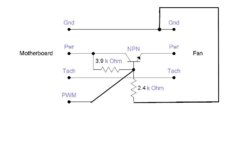

The PWM pin on the motherboard is designed to sink up to 5.25v, in your circuit it gets up to 12v! (though due to the resisters it can't draw much current, so probably won't damage anything)

The voltage to the base of the transistor is switching between 12v (on) to 6v (off) so it SHOULDN'T ever be turning off! If it is in fact working it's only because the transistor you chose has a very high base current.

Oh, and varying the resistor will NOT change the minimum speed of the fan. It will have no positive effect on the circuit, and might make the circuit (if it works now?) stop working completely.

How to fix it:

The PWM input should be connected directly to the base of the transistor between the resistor pair. And the bottom of the resistor pair should be connected to ground (not PWM).

Finally you should change the resistor values to: 3.9k between pwr and the base of the transistor, and 2.4k between the base of the transistor to ground. This will allow a higher current to the base of the transistor, making it more likely that you'll be in the switching region of the transistor, rather than the analog region.

Hope someone finds this useful

It looks like I'm a little late to this party, but seeing your schematic made be cringe!

I guess I should start off by mentioning that I am an electrical engineer, so I know what I'm talking about.

What's right:

On the positive side, you did keep ground as ground, and you chopped the 12v line (I've seen several attempts messing this up). If you chop the ground wire it will mess up the tach output. Other than that I'm surprised this circuit works at all.

What's wrong:

The PWM pin on the motherboard is designed to sink up to 5.25v, in your circuit it gets up to 12v! (though due to the resisters it can't draw much current, so probably won't damage anything)

The voltage to the base of the transistor is switching between 12v (on) to 6v (off) so it SHOULDN'T ever be turning off! If it is in fact working it's only because the transistor you chose has a very high base current.

Oh, and varying the resistor will NOT change the minimum speed of the fan. It will have no positive effect on the circuit, and might make the circuit (if it works now?) stop working completely.

How to fix it:

The PWM input should be connected directly to the base of the transistor between the resistor pair. And the bottom of the resistor pair should be connected to ground (not PWM).

Finally you should change the resistor values to: 3.9k between pwr and the base of the transistor, and 2.4k between the base of the transistor to ground. This will allow a higher current to the base of the transistor, making it more likely that you'll be in the switching region of the transistor, rather than the analog region.

Hope someone finds this useful

Last edited:

pvillegeek's design will work much better (as a 12-0 switch) if you get rid of the 2.4k. If not, your fan isn't going to be spinning as fast as it could be so heads up. Most fan's are going to have a hard time starting with pvillegeek's changes so WATCH THE FAN the first time you use it. It may hardly spin at all. His circuit only give the fan 4~5v MAX. DO NOT BUILD IT! I had it right the first time and an "electrical engineer" he should have seen what my intention was with the circuit. If you wan't, swap out both 10k resistors (in my design) with 4.7k if your transistor is low gain. At least the fan won't stall with my original design.

pvillegeek's design will work much better (as a 12-0 switch) if you get rid of the 2.4k. If not, your fan isn't going to be spinning as fast as it could be so heads up. Most fan's are going to have a hard time starting with pvillegeek's changes so WATCH THE FAN the first time you use it. It may hardly spin at all. His circuit only give the fan 4~5v MAX. DO NOT BUILD IT! I had it right the first time and an "electrical engineer" he should have seen what my intention was with the circuit. If you wan't, swap out both 10k resistors (in my design) with 4.7k if your transistor is low gain. At least the fan won't stall with my original design.