hello all

firstly im new to watercooling and this is my first time ive build one.

i have used the following EK 4.0 pump, phobya cpu waterblock, 2x120mm fan radiator and a phobya dual bay resevoir. i am running it like so pump---cpu waterblock---radiator---resevoir.

i have filled the system with feser blue coolent but when i turn the pump on it pumped the liquid around fast at start and the bubbles came through . when the bubbles stopped i looked in the resevoir and there was no flow at all. hope u can help thanks

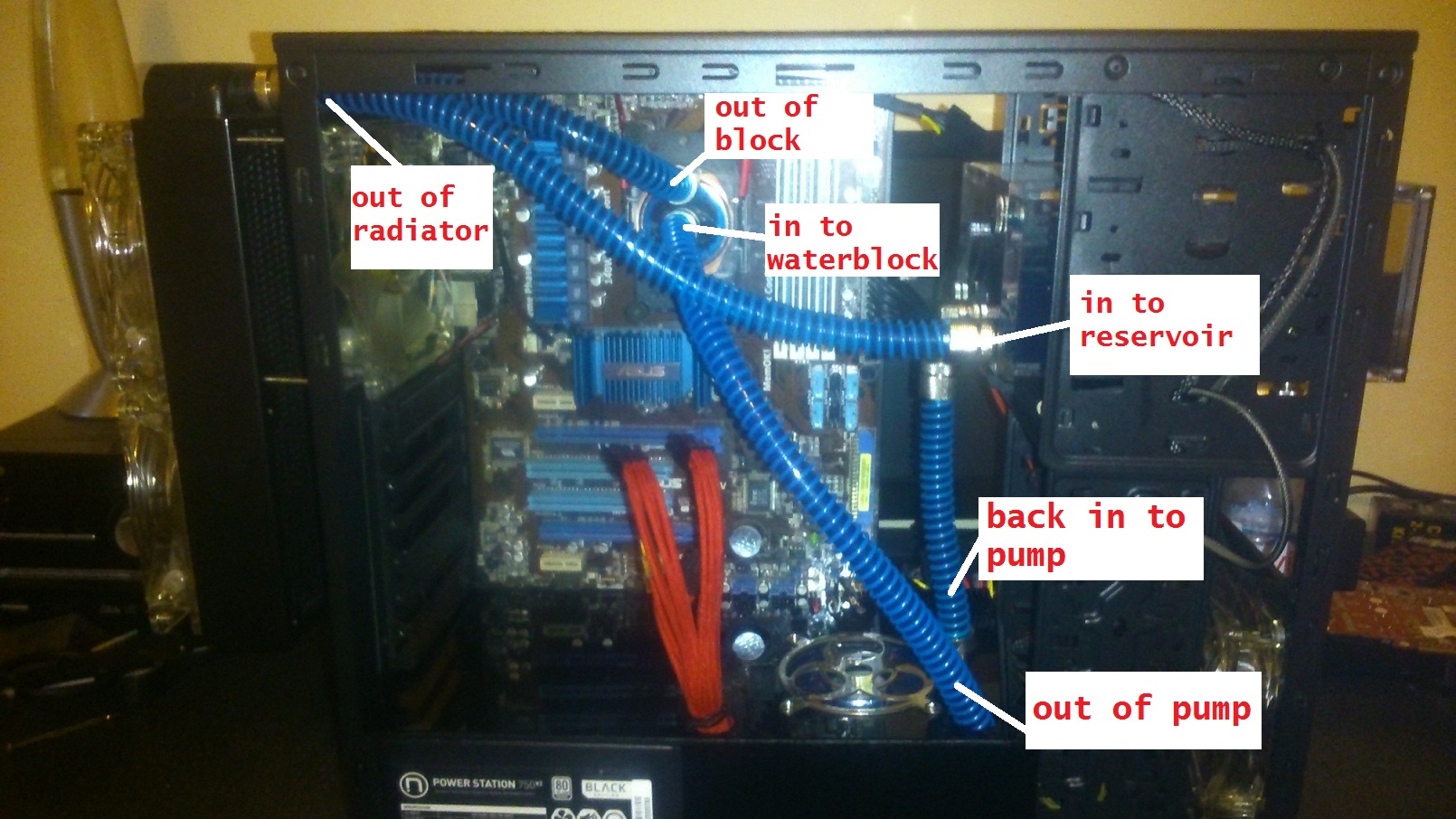

i have taken a picture to show how i set it up

firstly im new to watercooling and this is my first time ive build one.

i have used the following EK 4.0 pump, phobya cpu waterblock, 2x120mm fan radiator and a phobya dual bay resevoir. i am running it like so pump---cpu waterblock---radiator---resevoir.

i have filled the system with feser blue coolent but when i turn the pump on it pumped the liquid around fast at start and the bubbles came through . when the bubbles stopped i looked in the resevoir and there was no flow at all. hope u can help thanks

i have taken a picture to show how i set it up