srry for the lack of updates but the next installment is here

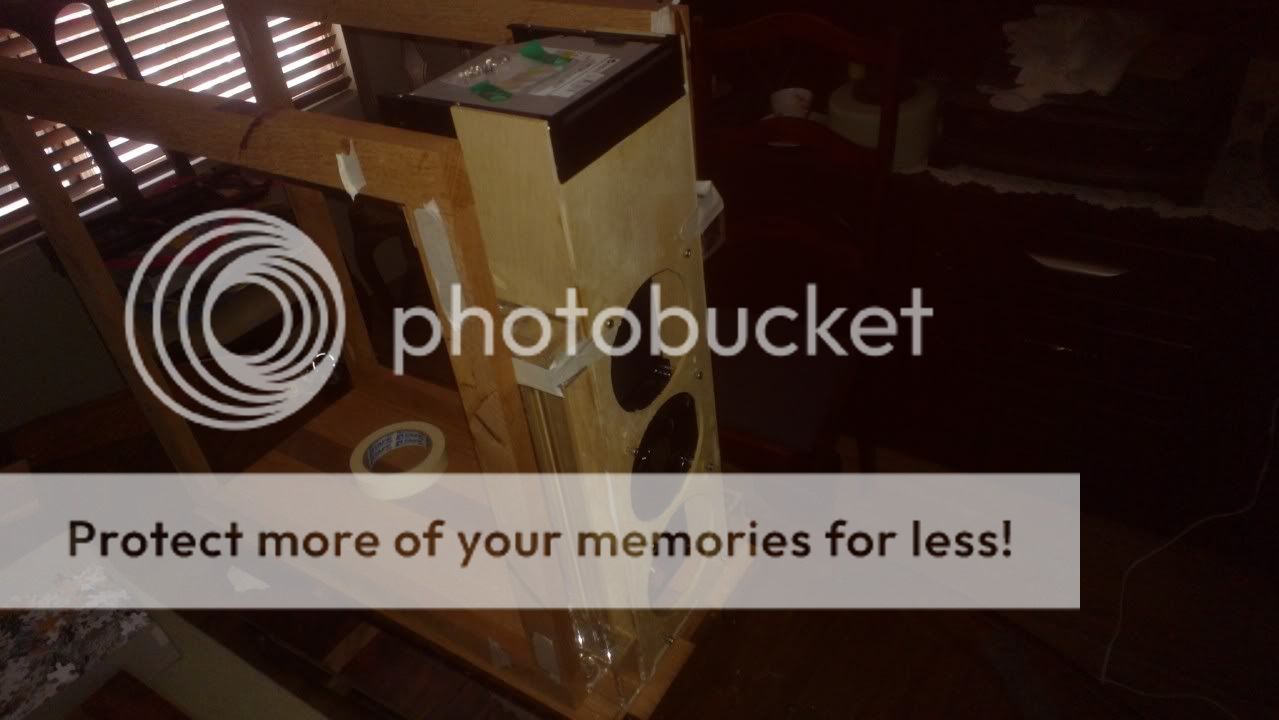

I received my slot load drive bay holder from PC Case gear the other day its a silverstone one and have tested it and it works perfectly and it will also hold 4 SSD's so my drive bays are now all sorted.

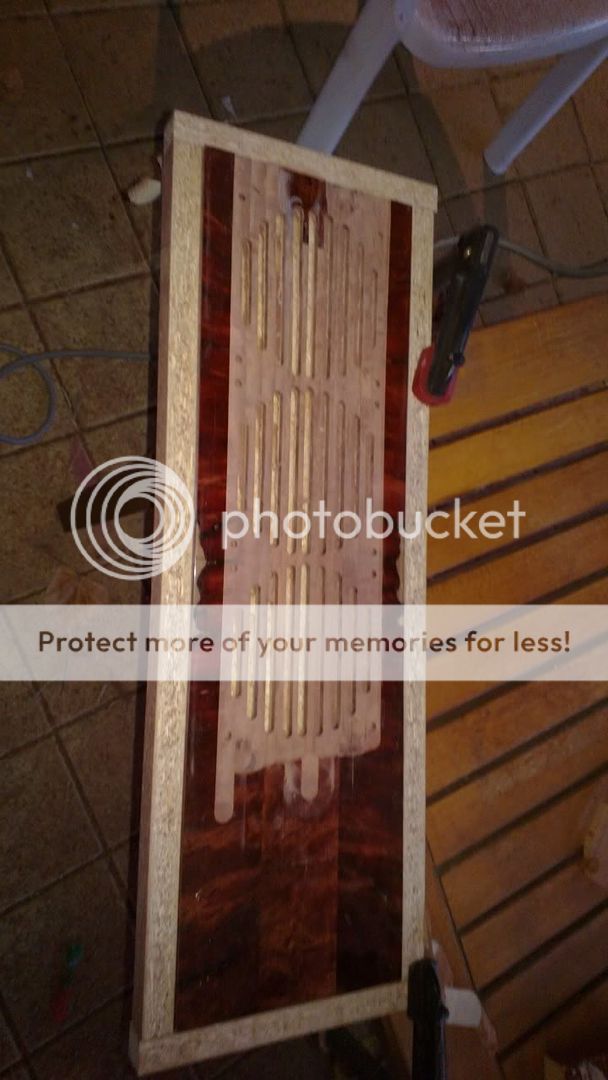

Well today I started work on the framework of the front panel, I drew the whole front panel out onto a piece of MDF to get sizes then cut a whole heap of MDF core Veneer paneling 4mm thick to make the framework i have only glued this together as it will get clad in the Jarrah Strips that you guys drooled over at the start of this thread

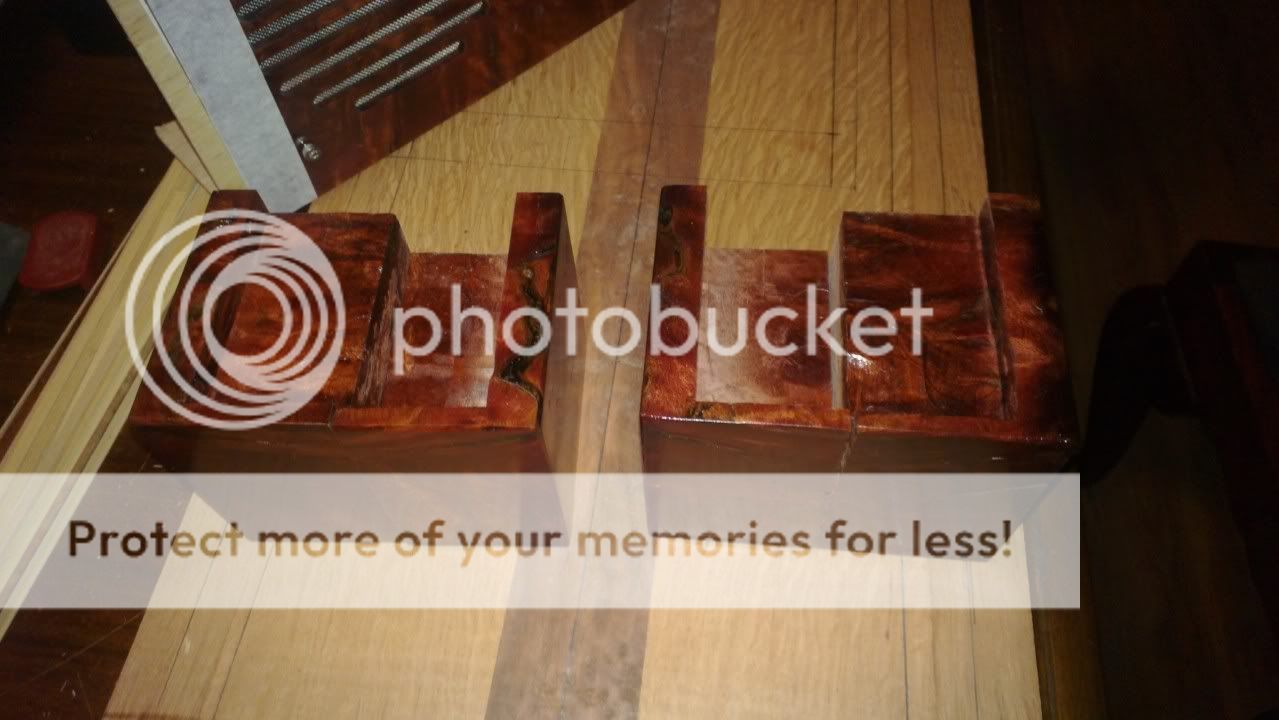

here is the framework under clamps and packers to make it all square

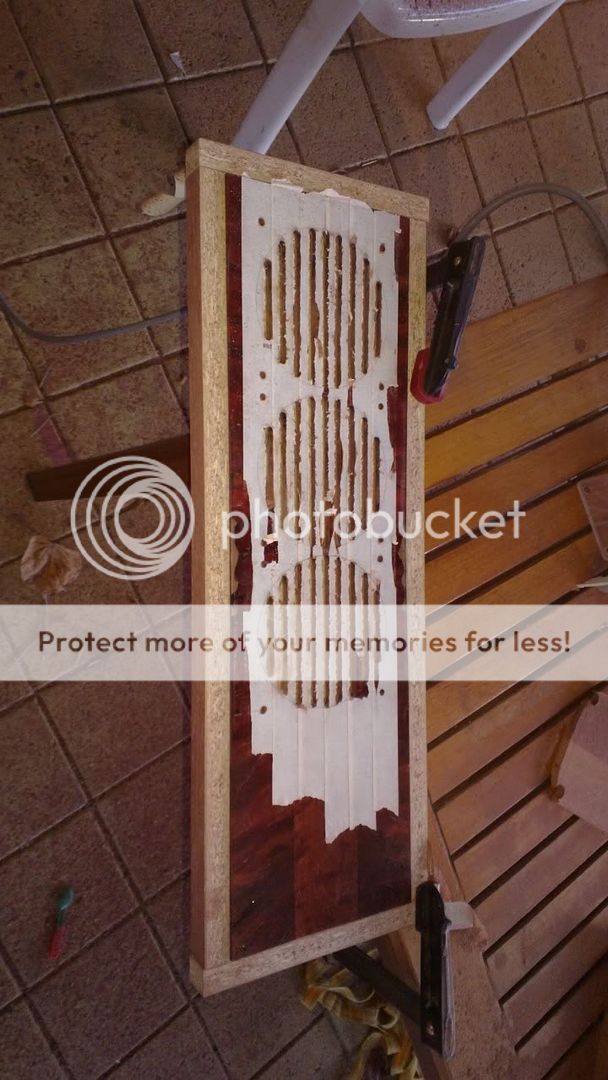

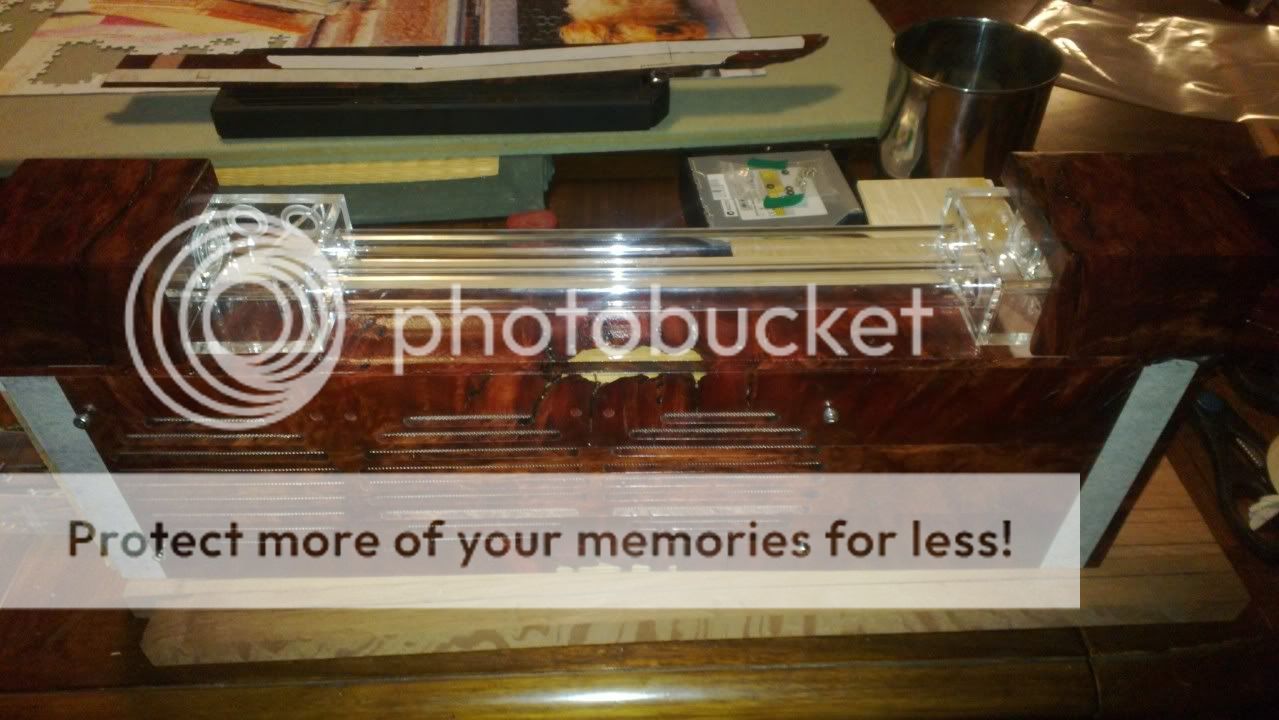

now after getting home and letting it dry out i got the radiator template i made earlier and routed out the fan holes that the fans will get bolted to with only one minor stuffup but im not fussed as it will not be seen (top radiator hole the template moved on me). And i then proceeded to check and make sure all my measurements are still correct and as you can see by the mock up im pretty spot on. the resivoirs will be raised so that they will be central in the height of the case.

on the front of this framework i will be attaching some very fine stainless steel mesh to act as my filter arrangement and the jarrah panneling will be routed to sort of look like a darth vadar mask to let the air flow through and placed in front of the mesh.

Here is what it looks like atm

srrybut you will have to ignore my wifes jigsaw pieces

at a total material cost of $7.00 AUD

at a total material cost of $7.00 AUD

at a total material cost of $7.00 AUD

at a total material cost of $7.00 AUD

Amazing work so far!

Amazing work so far!