DeLid or suffer the heat.

Delidding is in the air. I can't wait no more. *I'm running a 20 pass LinX stress test right now for my before delid test information. *In a few minutes I'm going to delid my 3570k. *

I wouldn't do this unless I was confident that I can do this and that my 3570k will benefit from it.

Right now my water cooled rig only has 1x120mm HWLABS Black ICE GTX Stealth radiator.

This is the testing water loop configuration for my first De-lidding test.

I have another radiator on back order at FrozenCPU and wanted to wait for it but I couldn't wait no more.

Photos from my adventure.

Officially Delidded. *No going back at this point in the game.

Cleaned up and ready to GO!

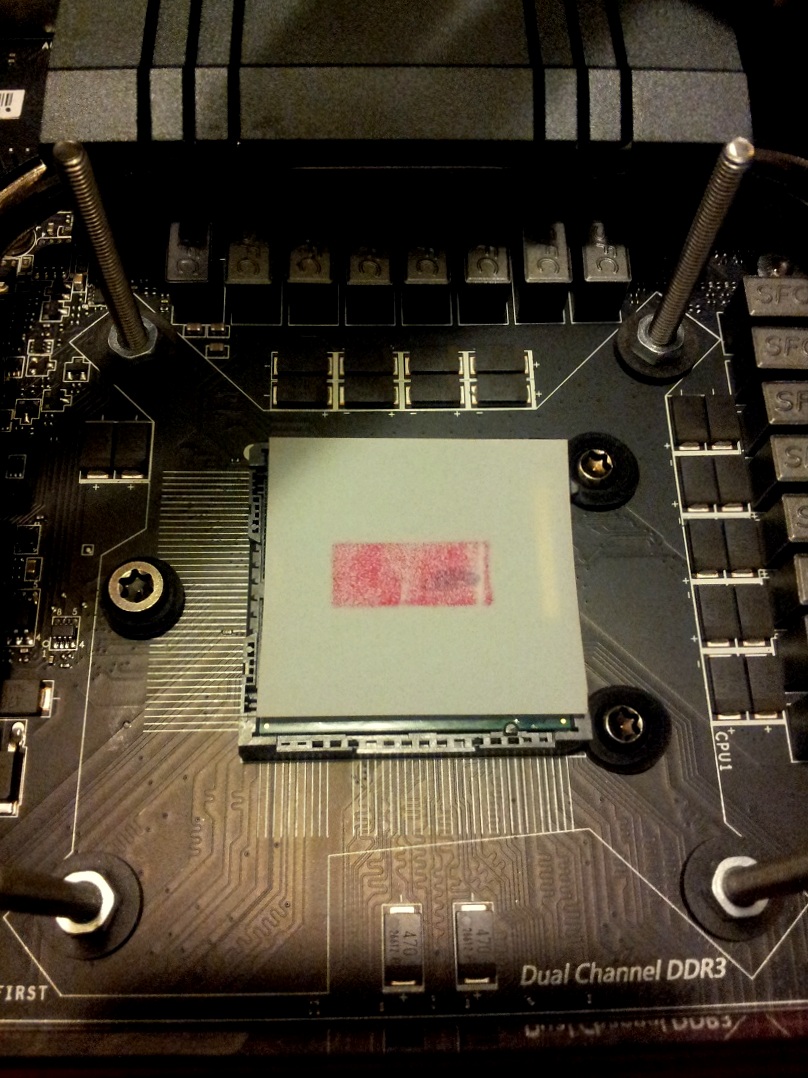

Contact Paper pressure test is a go!

Here is contact paper pressure test with my DT SNIPER water block on 3570k IHS and then 3570k direct die.

With IHS.

No IHS direct DIE!

Before Delidding.

Ambient Temp 26C

TIM IC Diamond 24

Temps under LinX load

83C 93C 89C 84C

http://valid.canardpc.com/show_oc.php?id=2531026

De-Lidded results.

Direct DIE Contact

Ambient Temps 25.5C

TIM IC Diamond 24

Temps under LinX load *

70C 80C 78C 74C

http://valid.canardpc.com/show_oc.php?id=2531139

Conclusion: By de-lidding my IB i5-3570k I was able to lower average core temps from

87.25C to 75.5C!!!!!

Intel left it to us to effectively cool IB. This works!!

Share your methods, lessons learned, and temps.