Wednesday, February 24th 2010

Nexus Technology Announces VCT-9000 CPU Cooler

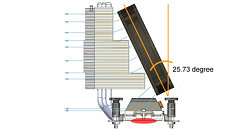

Nexus announces the VCT-9000 CPU cooler. The Nexus VCT-9000 cooler combines some of the most advanced technologies in the market used for CPU coolers: heat pipes directly on the CPU core, SkiveTek and 3 types of ultra-thin fins combined with a real silent PWM controlled 12cm fan at a 25 degree angle. This type op performance has never been this quiet before.

The 120mm fan is PWM controlled and the speed varies between an utterly low 500 and 1600 RPM creating the lowest possible noise-output. Further more the fan is fitted with for blue LED's. The 5 heatpipes - one of 8mm and four of 6mm diameter - are fitted using the advanced Heatpipe-On-Core technology to guarantee the fastest heat dissipation possible.The Nexus VCT-9000 has 3 different shape aluminium fins. The bottom section of the fins has a characteristic V-shape. This V-shape allows the air flow generated by the 12cm fan to reach the target area on top of the CPU core for effective cooling. When you compare this solution with side-blowing cpu coolers in the market you notice that this area is not touched by the airflow of most of these models. A clear advantage for the VCT-9000 compared to side-blowers.

The Nexus VCT-9000 is equipped with five heatpipes. The center heatpipe which is directly on the middle of the CPU is 8mm in diameter and provides massive cooling for the heart of the CPU. On either side of the 8mm heatpipe there are two highly efficient 6mm heatpipes. Heatpipe technology is the most effective way to quickly transport heat from one side to another. By placing the heatpipes directly on the core of the CPU you make use of this benefit in the most effective way. Heat is absorbed directly from the CPU core.Many coolers in the market have a baseplate on which the heatpipes are positions. Then there is a baseplate between the heatpipes and the CPU core. This inevitably causes loss of disipation and loss of performance.

The 120mm fan is PWM controlled and the speed varies between an utterly low 500 and 1600 RPM creating the lowest possible noise-output. Further more the fan is fitted with for blue LED's. The 5 heatpipes - one of 8mm and four of 6mm diameter - are fitted using the advanced Heatpipe-On-Core technology to guarantee the fastest heat dissipation possible.The Nexus VCT-9000 has 3 different shape aluminium fins. The bottom section of the fins has a characteristic V-shape. This V-shape allows the air flow generated by the 12cm fan to reach the target area on top of the CPU core for effective cooling. When you compare this solution with side-blowing cpu coolers in the market you notice that this area is not touched by the airflow of most of these models. A clear advantage for the VCT-9000 compared to side-blowers.

The Nexus VCT-9000 is equipped with five heatpipes. The center heatpipe which is directly on the middle of the CPU is 8mm in diameter and provides massive cooling for the heart of the CPU. On either side of the 8mm heatpipe there are two highly efficient 6mm heatpipes. Heatpipe technology is the most effective way to quickly transport heat from one side to another. By placing the heatpipes directly on the core of the CPU you make use of this benefit in the most effective way. Heat is absorbed directly from the CPU core.Many coolers in the market have a baseplate on which the heatpipes are positions. Then there is a baseplate between the heatpipes and the CPU core. This inevitably causes loss of disipation and loss of performance.

31 Comments on Nexus Technology Announces VCT-9000 CPU Cooler

Sure it might work fine on lower tdp chips but its gonna fail so badly on hotter ones. Why can't they write something like: 'look how pretty it is who cares about performance', and be done with it. And being Nexus its going to be pretty expensive.

( where as thermal right put grooves through the base plate so the pipes are get 360 degree contact point to absorb heat)

This way is cheaper to manufacture , consider the Xigamatek 1283, costs about 20-25 pounds here and on average not that far off true 120 X cooling.

Im sick of having to deal with pushpin systems on oversized tower coolers. If manufacturers listened to intently to the consumers about what they want in a cooler. then why are pushpins still a viable option??

Listen bub - If im willing to fork out for a 3rd party cooler then id also be willing to pay a few quid more for a backplate for installation none of this 'easy-way-out' pushpin bollocks.

I'm not sure what coolers are you talking about that don't have grooves inside the baseplate beside Scythe which btw offers great value for money.

Don't mistake a marketing gimmick with something that really works. And a decent hdt heatsink, ie Thors hammer, is not very cheap:

www.xbitlabs.com/articles/coolers/display/alpenfoehn-nordwand_7.html

*edit*

At guy above, my xig 1283 beat my true 120 x by 5 c under-load on the CPU in my system specs same case but no water-cooling obviously :p

its all about choosing the right fans for the right heatsink.

For example the cooler you metnioned ( thors hammer) would probably benefit from high pressure fans such as Scyth gentle typhoon.

Thermal-rights coolers are over rated and not worth the pennies in my opinion ( only got mine as it was second hand)

Its easily done as well just seems no on in the industry has a head on their shoulders, just copying other companies all the time.

( I understand that sometimes my descriptions are shoddy, so just imagine a 16mm heatpipe squashed flat whilst still remaining 3 mm thick so phase can still occur)

Making air flow "kink round a corner" is only causing resistance. And is there any airflow at the centre of the fan? Not much. Fins should be SHORTEST there. Not a clever design IMO except for (possibly) getting a bigger cooler and bigger fan into a standard height case.

Oh, and how many degrees is that? Like the information is important? No it isnt.

Also bending it would be no problem, they manage to bend heat pipes already after all.

The reasons manufacturers use 4mm, 6mm, and 8mm heatpipes is that a majority of them buy the heat columns from other manufacturers. These are standard sizes and fit in standard manufacturing processes and the machines they use to shape and place the heatpipes.

Failure rates in working with 10mm and above size heatpipes are higher, the unit costs are higher and nobody has the tools to work with them.

These companies like Nexus, Gelid, Xigmatek, and Noctua don't own the factories that produce their coolers. They just spec the fans and have another company stack the fins and bend the heatpipes. They use ODMs who save costs by using readily available technology with different heatsink stacks etc.

There are only a few companies with their own factories that can produce the fans and the coolers in large enough scale to be cost effective for most people. For example Cooler Master who have these kind of factories and technology, I am sure they would build your dream cooler with 16mm heatpipe.

All you have to do is invest in the tooling, presses and assembly line. It's a good deal if you have $2 million dollars or so. Since we aren't talking about parts for the space shuttle, so this kind of CPU cooler will never be built. That is unless you have 2 million to invest.:D

Won't cost the OEMS all that much.

I've managed to bend and flatten copper pipe of that diameter by hand by the by.

Just took time, a machine could do it much faster.

Hells they could even just sandwich two separate bars of copper together and then then solder down both sides . then its only a case of sealing the ends after adding the gas.

I've put a lot of thought into it : ]

Aswell as that I've seen one cooling company specialise in larger heatpipes, I'm sure they could easily adapt the process.

I imagine they'd be the first to do it as well.

They only make coolers for servers mind you.

The fins are fine, the fan postition is fine, and the shroud should help performance (and the flames mean...u know it, its gotta be faster...lol)

It does seems to have some issues though, at least I think it might.

Staggering the fins is nice, but how much surface area is lost?

Is the fan incredibly loud to make up for this loss, or is the cooler an undeachiever?

Then the offset worries me.... the direction of airflow, normally pointing at the rear exhaust, leaves the offset of the pipes right into competition with room from the motherboard caps(potentially).

- V8, V10

- Hyper N520, Hyper N 620

- Hyper 212 Plus

When you see a company like Xigmatek selling the 1283, and another company selling the exact same thing like an OCZ Vendetta 2, either they both buy it from the same company or one of the companies selling it makes it. The thing about copies is that the factory selling to Xigmatek can also sell the model to others. It isn't only Cooler Master that has the tools, if you want you could pitch your cooler to Zalman.

Back on topic, there are some typos on the press release quote here on TP. Also the Nexus cooler seems more designed by marketing people than engineers. Most of the airflow is not going to change direction and blow through the stacked heatpipes. The air is just going to follow the paths of least resistance and go around or down.

I know for example the 1283 was actually originally designed by the company Zaward.

Also yeah that be great I'll appreciate it!

Seeing as I managed to shape a copper pipe myself, I wonder if I could construct a complete heat-sink by hand ha ha .

oooh think I'll invest in some aluminium sheets when I have some cash.

Obviously I won't be able to use fancy gas in my cooler though :[ with have to settle for a small amount of distilled water .