Samsung to Build $17 Billion Silicon Manufacturing Plant in the US by 2023

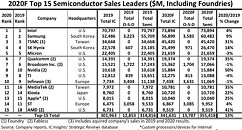

Samsung has been one of the world's biggest foundries and one of three big players still left in the leading-edge semiconductor process development and manufacturing. However, the Korean giant is always seeking ways to improve its offerings, especially for Western customers. Today, it is reported that Samsung has reportedly talked with regulators in Texas, New York, and Arizona about building a $17 billion silicon manufacturing facility in the United States. The supposed factory is going to be located near Austin, Texas, and is supposed to offer around 1800 jobs. If the deal is approved and Samsung manages to complete the project on time, the factory is supposed to start mass production in Q4 of 2023.

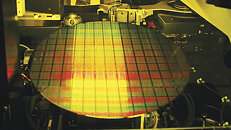

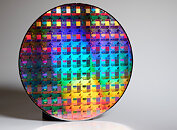

What process is Samsung going to manufacture in the new fab? Well, current speculations are pointing out to the 3 nm node, with Samsung's special GAAFET (Gate All Around FET) technology tied to the new node. The fab is also expected to make use of extreme ultraviolet (EUV) lithography for manufacturing. Samsung already has a facility in the US called S2, however, that will not be upgraded as it is still serving a lot of clients. Instead, the company will build new facilities to accommodate the demand for newer nodes. It is important to note that Samsung will not do any R&D work in the new fab, and the company will only manufacture the silicon there.

What process is Samsung going to manufacture in the new fab? Well, current speculations are pointing out to the 3 nm node, with Samsung's special GAAFET (Gate All Around FET) technology tied to the new node. The fab is also expected to make use of extreme ultraviolet (EUV) lithography for manufacturing. Samsung already has a facility in the US called S2, however, that will not be upgraded as it is still serving a lot of clients. Instead, the company will build new facilities to accommodate the demand for newer nodes. It is important to note that Samsung will not do any R&D work in the new fab, and the company will only manufacture the silicon there.