UMC is Feeling the Pressure from Chinese Foundries

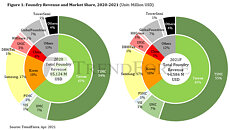

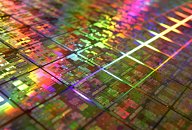

The chip shortage discussion has been very focused on TSMC for some reason and although the company is without a doubt the world's leading foundry, the company is making its living from being a cutting edge foundry, whereas much of the components that there's a shortage of are made on far older nodes at many different foundries. Taiwanese UMC is one of the foundries that makes many of the automotive semiconductors, as well as key components when it comes to power regulation and is considered the world's third largest foundry.

Until 2018, UMC was competing head on with TSMC, although the company was always about a node behind TSMC, which led to a management team decision to slow down its node transition and instead to focus on speciality technologies. The company has done well in this niche, with a revenue of about US$6.2 billion in 2020. However, UMC is starting to feel the pressure from its competitors in China, as the PRC government is making a push for local production of local IC designs.

Until 2018, UMC was competing head on with TSMC, although the company was always about a node behind TSMC, which led to a management team decision to slow down its node transition and instead to focus on speciality technologies. The company has done well in this niche, with a revenue of about US$6.2 billion in 2020. However, UMC is starting to feel the pressure from its competitors in China, as the PRC government is making a push for local production of local IC designs.