- Joined

- Aug 19, 2017

- Messages

- 2,524 (0.96/day)

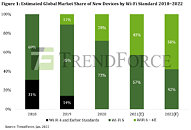

Exponential demand growth for remote and unmanned terminals in smart home, logistics, manufacturing and other end-user applications has driven iterative updates in Wi-Fi technology. Among the current generations of technologies, Wi-Fi 5 (802.11ac) is mainstream while Wi-Fi 6 and 6E (802.11ax) are at promotional stages, according to TrendForce's investigations. In order to meet the connection requirements of industry concepts such as the Metaverse, many major manufacturers have trained their focus on the faster and more stable next generation 802.11be Wi-Fi standard amendment, commonly known as Wi-Fi 7. Considering technical characteristics, maturity, and product certification status, Wi-Fi 6 and 6E are expected to surpass Wi-Fi 5 to become mainstream technology in 2022, with global market share expected to reach 58%.

TrendForce states, in common residential applications of Wi-Fi, Wi-Fi 6E supports 6 GHz and expands bandwidth by at least 1200 MHz, delivering higher efficiency, throughput, and security than Wi-Fi 6, and can optimize remote work, VR/AR, and other user experiences. Moreover, in terms of the vertical IoT sector with the highest output value, smart manufacturing still mostly employs Ethernet and 4G/5G mobile networks as the central communication technologies in current smart factories. However, as early as 2019, major British aerospace equipment manufacturer, Mettis Aerospace, and the Wireless Broadband Alliance (WBA) conducted phased testing of the practicality of Wi-Fi 6 in factories, and they believe that Wi-Fi 6 can be widely adopted for manufacturing.

Market not yet mature, practical application of Wi-Fi 7 must wait until the end of 2023 at the earliest

TrendForce believes that the introduction of Industry 4.0 technology tools will become more common and the degree of digitalization within companies will increase in the post-pandemic era, with 5G and Wi-Fi expected to bring complementary and synergistic effects to the manufacturing field. The primary reason for this is that 5G characteristics include wide connection, large bandwidth, and low latency. In addition, multi-access edge computing (MEC) and standalone (SA) network slicing can improve computing power and flexibility, all of which significantly upgrade smart manufacturing tools. Although the transmission range of Wi-Fi is small, it resists interference and enhances the physical penetration of wireless signals at smart manufacturing locations. Wi-Fi also reduces the cost of 5G distributed antennas and small base stations while extending communications range and improving equipment battery life.

Looking forward to next generation Wi-Fi 7, companies such as MediaTek, Qualcomm, and Broadcom, are already laying the groundwork for their forays into this standard. TrendForce believes, even though focus is currently shifting to Wi-Fi 7, scheduled application of Wi-Fi 7 is expected to fall between the end of 2023 and the beginning of 2024. Challenges remain in terms of overall development and issues such as equipment investment, spectrum usage, deployment cost, and terminal equipment penetration must all be overcome in order to demonstrate the technical benefits of Wi-Fi 7.

View at TechPowerUp Main Site

TrendForce states, in common residential applications of Wi-Fi, Wi-Fi 6E supports 6 GHz and expands bandwidth by at least 1200 MHz, delivering higher efficiency, throughput, and security than Wi-Fi 6, and can optimize remote work, VR/AR, and other user experiences. Moreover, in terms of the vertical IoT sector with the highest output value, smart manufacturing still mostly employs Ethernet and 4G/5G mobile networks as the central communication technologies in current smart factories. However, as early as 2019, major British aerospace equipment manufacturer, Mettis Aerospace, and the Wireless Broadband Alliance (WBA) conducted phased testing of the practicality of Wi-Fi 6 in factories, and they believe that Wi-Fi 6 can be widely adopted for manufacturing.

Market not yet mature, practical application of Wi-Fi 7 must wait until the end of 2023 at the earliest

TrendForce believes that the introduction of Industry 4.0 technology tools will become more common and the degree of digitalization within companies will increase in the post-pandemic era, with 5G and Wi-Fi expected to bring complementary and synergistic effects to the manufacturing field. The primary reason for this is that 5G characteristics include wide connection, large bandwidth, and low latency. In addition, multi-access edge computing (MEC) and standalone (SA) network slicing can improve computing power and flexibility, all of which significantly upgrade smart manufacturing tools. Although the transmission range of Wi-Fi is small, it resists interference and enhances the physical penetration of wireless signals at smart manufacturing locations. Wi-Fi also reduces the cost of 5G distributed antennas and small base stations while extending communications range and improving equipment battery life.

Looking forward to next generation Wi-Fi 7, companies such as MediaTek, Qualcomm, and Broadcom, are already laying the groundwork for their forays into this standard. TrendForce believes, even though focus is currently shifting to Wi-Fi 7, scheduled application of Wi-Fi 7 is expected to fall between the end of 2023 and the beginning of 2024. Challenges remain in terms of overall development and issues such as equipment investment, spectrum usage, deployment cost, and terminal equipment penetration must all be overcome in order to demonstrate the technical benefits of Wi-Fi 7.

View at TechPowerUp Main Site