- Joined

- Aug 19, 2017

- Messages

- 3,114 (1.09/day)

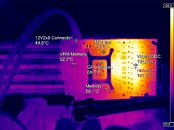

Igor's Lab has run independent testing and thermal analysis of NVIDIA's latest GeForce RTX 50-series graphics cards, including the add-in card partner design RTX 5080, 5070 Ti, and 5060 Ti, which are now attracting attention for surprising thermal "hotspots" on the back of their PCBs. These hotspots are just the areas on PCB that get hot under load, and not the "Hot Spot" sensor NVIDIA removed with RTX 50 series. Infrared tests have shown temperatures climbing above 100°C in the power delivery region, even though the GPU die stays below 80°C. This isn't a problem with the silicon but with concentrated heating in clusters of thin copper planes and via arrays. Card makers like Palit, PNY, and MSI have all seen the same issue since they closely follow NVIDIA's reference PCB layout and use similar cooler mounting. A big part of the trouble comes down to how PCB designers and cooler engineers work separately.

NVIDIA's Thermal Design Guide gives AIC partners detailed power-loss budgets, listing worst-case dissipation for the GPU, memory, NVVDD and FBVDDQ rails, inductors, MOSFETs, and other components, and it recommends ideal thermal interface materials and mounting pressures. The guide assumes that even heat is spreading and that there is perfect airflow in a wind tunnel, but actual consumer PCs don't match those conditions. Multi-layer PCBs force high currents through 35 to 70 µm copper layers, which join at tight via clusters under the VRMs. Without dedicated thermal bridges or reinforced vias, these areas become bottlenecks where heat builds up, and the standard backplate plus heat-pipe layout can't pull it away fast enough.

This hotspot issue isn't limited to the newest Blackwell GPUs. Even the previous-generation GeForce RTX 4090, which was engineered for up to 600 W of heat dissipation with multiple vapor chambers and a three-slot cooler, showed a similar pattern. Thermographic snapshots of prototype Ada architecture boards revealed rear-side VRM zones reaching the mid-70s Celsius while the GPU die sat in the low-60s. Internal versions of NVIDIA's guide were redacted to protect internal details, and no special note was made to reinforce the backplate in that spot. As a result, partners assumed the standard backplate contact area was sufficient and didn't add any extra cooling measures. Fortunately, simple tweaks can make a big difference. In Igor's Lab tests, placing a thin thermal pad or a small amount of conductive putty between the hotspot area and the backplate dropped peak VRM temperatures by 8 to 12 °C under the same load.

View at TechPowerUp Main Site | Source

NVIDIA's Thermal Design Guide gives AIC partners detailed power-loss budgets, listing worst-case dissipation for the GPU, memory, NVVDD and FBVDDQ rails, inductors, MOSFETs, and other components, and it recommends ideal thermal interface materials and mounting pressures. The guide assumes that even heat is spreading and that there is perfect airflow in a wind tunnel, but actual consumer PCs don't match those conditions. Multi-layer PCBs force high currents through 35 to 70 µm copper layers, which join at tight via clusters under the VRMs. Without dedicated thermal bridges or reinforced vias, these areas become bottlenecks where heat builds up, and the standard backplate plus heat-pipe layout can't pull it away fast enough.

This hotspot issue isn't limited to the newest Blackwell GPUs. Even the previous-generation GeForce RTX 4090, which was engineered for up to 600 W of heat dissipation with multiple vapor chambers and a three-slot cooler, showed a similar pattern. Thermographic snapshots of prototype Ada architecture boards revealed rear-side VRM zones reaching the mid-70s Celsius while the GPU die sat in the low-60s. Internal versions of NVIDIA's guide were redacted to protect internal details, and no special note was made to reinforce the backplate in that spot. As a result, partners assumed the standard backplate contact area was sufficient and didn't add any extra cooling measures. Fortunately, simple tweaks can make a big difference. In Igor's Lab tests, placing a thin thermal pad or a small amount of conductive putty between the hotspot area and the backplate dropped peak VRM temperatures by 8 to 12 °C under the same load.

View at TechPowerUp Main Site | Source