-

Welcome to TechPowerUp Forums, Guest! Please check out our forum guidelines for info related to our community.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best way to apply paste to a direct-contact heatpipe cooler?

- Thread starter adcx64

- Start date

CAPSLOCKSTUCK

Spaced Out Lunar Tick

- Joined

- Feb 26, 2013

- Messages

- 8,578 (1.92/day)

- Location

- llaregguB...WALES

| System Name | Party On |

|---|---|

| Processor | Xeon w 3520 |

| Motherboard | DFI Lanparty |

| Cooling | Big tower thing |

| Memory | 6 gb Ballistix Tracer |

| Video Card(s) | HD 7970 |

| Case | a plank of wood |

| Audio Device(s) | seperate amp and 6 big speakers |

| Power Supply | Corsair |

| Mouse | cheap |

| Keyboard | under going restoration |

Have a read of this too

https://www.pugetsystems.com/labs/articles/Thermal-Paste-Application-Techniques-170/

peche

Thermaltake fanboy

- Joined

- Nov 7, 2014

- Messages

- 6,709 (1.74/day)

- Location

- San Jose, Costa Rica

| System Name | Athenna |

|---|---|

| Processor | intel i7 3770 *Dellided* |

| Motherboard | GIGABYTE GA-Z68X-UD3H-B3 Rev. 1.1 |

| Cooling | Thermaltake Water 3.0 Pro + Tt Riing12 x2 / Tt ThunderBlade / Gelid Slim 120UV fans |

| Memory | 16GB DRR3 Kingoston with Custom Tt spreaders + HyperX Fan |

| Video Card(s) | GeForce GTX 980 4GB Nvidia Sample |

| Storage | Crucial M4 SSD 64GB's / Seagate Barracuda 2TB / Seagate Barracuda 320GB's |

| Display(s) | 22" LG FLATRON 1920 x 1280p |

| Case | Thermaltake Commander G42 Window |

| Audio Device(s) | On-board Dolby 5.1+ Kingston HyperX Cloud 1 |

| Power Supply | Themaltake TR2 700W 80plus bronce & APC Pro backup 1000Va |

| Mouse | Tt eSports Level 10M Rev 1.0 Diamond Black & Tt Conkor "L" mouse pad |

| Keyboard | Tt eSports KNUCKER |

| Software | windows 10x64Pro |

| Benchmark Scores | well I've fried a 775' P4 12 years ago, that counts? |

direct-contact heatpipe cooler?

You mean laptop cooler?

or which cooler is it, please specify,

Regards,

newtekie1

Semi-Retired Folder

- Joined

- Nov 22, 2005

- Messages

- 28,473 (4.00/day)

- Location

- Indiana, USA

| Processor | Intel Core i7 10850K@5.2GHz |

|---|---|

| Motherboard | AsRock Z470 Taichi |

| Cooling | Corsair H115i Pro w/ Noctua NF-A14 Fans |

| Memory | 32GB DDR4-3600 |

| Video Card(s) | RTX 2070 Super |

| Storage | 500GB SX8200 Pro + 8TB with 1TB SSD Cache |

| Display(s) | Acer Nitro VG280K 4K 28" |

| Case | Fractal Design Define S |

| Audio Device(s) | Onboard is good enough for me |

| Power Supply | eVGA SuperNOVA 1000w G3 |

| Software | Windows 10 Pro x64 |

Should I just follow the normal pea sized method?

Yes.

- Joined

- Dec 29, 2010

- Messages

- 3,876 (0.74/day)

| Processor | AMD 5900x |

|---|---|

| Motherboard | Asus x570 Strix-E |

| Cooling | Hardware Labs |

| Memory | G.Skill 4000c17 2x16gb |

| Video Card(s) | RTX 3090 |

| Storage | Sabrent |

| Display(s) | Samsung G9 |

| Case | Phanteks 719 |

| Audio Device(s) | Fiio K5 Pro |

| Power Supply | EVGA 1000 P2 |

| Mouse | Logitech G600 |

| Keyboard | Corsair K95 |

Should I just follow the normal pea sized method?

If the pipes are exposed which is typical of direct contact, then you SPREAD. Pea will get caught in the ridges.

eidairaman1

The Exiled Airman

- Joined

- Jul 2, 2007

- Messages

- 44,359 (6.79/day)

- Location

- Republic of Texas (True Patriot)

| System Name | PCGOD |

|---|---|

| Processor | AMD FX 8350@ 5.0GHz |

| Motherboard | Asus TUF 990FX Sabertooth R2 2901 Bios |

| Cooling | Scythe Ashura, 2×BitFenix 230mm Spectre Pro LED (Blue,Green), 2x BitFenix 140mm Spectre Pro LED |

| Memory | 16 GB Gskill Ripjaws X 2133 (2400 OC, 10-10-12-20-20, 1T, 1.65V) |

| Video Card(s) | AMD Radeon 290 Sapphire Vapor-X |

| Storage | Samsung 840 Pro 256GB, WD Velociraptor 1TB |

| Display(s) | NEC Multisync LCD 1700V (Display Port Adapter) |

| Case | AeroCool Xpredator Evil Blue Edition |

| Audio Device(s) | Creative Labs Sound Blaster ZxR |

| Power Supply | Seasonic 1250 XM2 Series (XP3) |

| Mouse | Roccat Kone XTD |

| Keyboard | Roccat Ryos MK Pro |

| Software | Windows 7 Pro 64 |

I use spread method no matter the cooler

peche

Thermaltake fanboy

- Joined

- Nov 7, 2014

- Messages

- 6,709 (1.74/day)

- Location

- San Jose, Costa Rica

| System Name | Athenna |

|---|---|

| Processor | intel i7 3770 *Dellided* |

| Motherboard | GIGABYTE GA-Z68X-UD3H-B3 Rev. 1.1 |

| Cooling | Thermaltake Water 3.0 Pro + Tt Riing12 x2 / Tt ThunderBlade / Gelid Slim 120UV fans |

| Memory | 16GB DRR3 Kingoston with Custom Tt spreaders + HyperX Fan |

| Video Card(s) | GeForce GTX 980 4GB Nvidia Sample |

| Storage | Crucial M4 SSD 64GB's / Seagate Barracuda 2TB / Seagate Barracuda 320GB's |

| Display(s) | 22" LG FLATRON 1920 x 1280p |

| Case | Thermaltake Commander G42 Window |

| Audio Device(s) | On-board Dolby 5.1+ Kingston HyperX Cloud 1 |

| Power Supply | Themaltake TR2 700W 80plus bronce & APC Pro backup 1000Va |

| Mouse | Tt eSports Level 10M Rev 1.0 Diamond Black & Tt Conkor "L" mouse pad |

| Keyboard | Tt eSports KNUCKER |

| Software | windows 10x64Pro |

| Benchmark Scores | well I've fried a 775' P4 12 years ago, that counts? |

If the pipes are exposed Its pretty great to tint a little bit of tim to them... for making a greater bond surface....I use spread method no matter the cooler

Regards,

- Joined

- Oct 2, 2004

- Messages

- 13,875 (1.84/day)

| System Name | Dark Monolith |

|---|---|

| Processor | AMD Ryzen 7 5800X3D |

| Motherboard | ASUS Strix X570-E |

| Cooling | Arctic Cooling Freezer II 240mm + 2x SilentWings 3 120mm |

| Memory | 64 GB G.Skill Ripjaws V Black 3600 MHz |

| Video Card(s) | XFX Radeon RX 9070 XT Mercury OC Magnetic Air |

| Storage | Seagate Firecuda 530 4 TB SSD + Samsung 850 Pro 2 TB SSD + Seagate Barracuda 8 TB HDD |

| Display(s) | ASUS ROG Swift PG27AQDM 240Hz OLED |

| Case | Silverstone Kublai KL-07 |

| Audio Device(s) | Sound Blaster AE-9 MUSES Edition + Altec Lansing MX5021 2.1 Nichicon Gold |

| Power Supply | BeQuiet DarkPower 11 Pro 750W |

| Mouse | Logitech G502 Proteus Spectrum |

| Keyboard | UVI Pride MechaOptical |

| Software | Windows 11 Pro |

If pipes aren't smoothed out almost perfectly it's almost better to apply tiny bit more TIM than necessary to fill the slightly bigger gaps. It's better to have slightly more thermal paste than having an air gab which is the worst heat conductor you can imagine.

- Joined

- Jan 17, 2010

- Messages

- 12,340 (2.20/day)

- Location

- Oregon

| System Name | Juliette // My HTPC |

|---|---|

| Processor | Intel i7 9700K // AMD Ryzen 5 5600G |

| Motherboard | ASUS Prime Z390X-A // ASRock B550 ITX-AC |

| Cooling | Noctua NH-U12 Black // Stock |

| Memory | Corsair DDR4 3600 32gb //G.SKILL Trident Z Royal Series 16GB (2 x 8GB) 3600 |

| Video Card(s) | ASUS RTX4070 OC// ASUS RTX 4060 OC |

| Storage | Samsung 970 EVO NVMe 1Tb, Intel 665p Series M.2 2280 1TB // Samsung 1Tb SSD |

| Display(s) | ASUS VP348QGL 34" Quad HD 3440 x 1440 // 55" LG 4K SK8000 Series |

| Case | Seasonic SYNCRO Q7// Silverstone Granada GD05 |

| Audio Device(s) | Focusrite Scarlett 4i4 // HDMI to Samsung HW-R650 sound bar |

| Power Supply | Seasonic SYNCRO 750 W // CORSAIR Vengeance 650M |

| Mouse | G903 and a Master Mouse MM710/No mouse, MS game copntroller |

| Keyboard | EVGA / Logitech K400 |

| Software | Windows 11 Pro // Windows 10 Pro |

I never spread. Just squish and its good. Peche direct contact is like the CM 212 not a laptop

As far as Direct contact Ive use as little as a grain of rice and not spread. Always worked for me. The only one I spread is CPUs like the old Duron type with no heat spreader

The only thing you could do wrong is use too much, reuse the paste or forget to take the sticker off

As far as Direct contact Ive use as little as a grain of rice and not spread. Always worked for me. The only one I spread is CPUs like the old Duron type with no heat spreader

The only thing you could do wrong is use too much, reuse the paste or forget to take the sticker off

Last edited:

- Joined

- Nov 1, 2008

- Messages

- 4,213 (0.70/day)

- Location

- Vietnam

| System Name | Gaming System / HTPC-Server |

|---|---|

| Processor | i7 8700K (@4.8 Ghz All-Core) / R7 5900X |

| Motherboard | Z370 Aorus Ultra Gaming / MSI B450 Mortar Max |

| Cooling | CM ML360 / CM ML240L |

| Memory | 16Gb Hynix @3200 MHz / 16Gb Hynix @3000Mhz |

| Video Card(s) | Zotac 3080 / Colorful 1060 |

| Storage | 750G MX300 + 2x500G NVMe / 40Tb Reds + 1Tb WD Blue NVMe |

| Display(s) | LG 27GN800-B 27'' 2K 144Hz / Sony TV |

| Case | Xigmatek Aquarius Plus / Corsair Air 240 |

| Audio Device(s) | On Board Realtek |

| Power Supply | Super Flower Leadex III Gold 750W / Andyson TX-700 Platinum |

| Mouse | Logitech G502 Hero / K400+ |

| Keyboard | Wooting Two / K400+ |

| Software | Windows 10 x64 |

| Benchmark Scores | Cinebench R15 = 1542 3D Mark Timespy = 9758 |

I always just go with a grain of rice in the middle and a smidgen in each corner.

Though I have lapped all of my cpus so even just a grain of rice blob covers 66% of the CPU.

Every other method I have tried, give me higher temps and I've found that the less compound, the better.

Though I have lapped all of my cpus so even just a grain of rice blob covers 66% of the CPU.

Every other method I have tried, give me higher temps and I've found that the less compound, the better.

- Joined

- Oct 29, 2012

- Messages

- 842 (0.18/day)

- Location

- Germany

| System Name | Perf/price king /w focus on low noise and TDP |

|---|---|

| Processor | Intel Xeon E3-1230 v2 |

| Motherboard | Gigabyte GA-B75M-D3H |

| Cooling | Thermalright HR-02 Macho Rev.A (BW) |

| Memory | 16GB Corsair Vengeance LP Black |

| Video Card(s) | Gigabyte GTX 670 OC |

| Storage | 525GB Crucial MX300 & 256GB Samsung 830 Series |

| Display(s) | Home: LG 29UB65-P & Work: LG 34UB88-B |

| Case | Fractal Design Arc Mini |

| Audio Device(s) | Asus Xonar Essence STX /w Sennheiser HD 598 |

| Power Supply | be quiet! Straight Power CM E9 80+ Gold 480W |

| Mouse | Roccat Kone XTD optical |

| Keyboard | SteelSeries Apex M500 |

| Software | Win10 |

peche

Thermaltake fanboy

- Joined

- Nov 7, 2014

- Messages

- 6,709 (1.74/day)

- Location

- San Jose, Costa Rica

| System Name | Athenna |

|---|---|

| Processor | intel i7 3770 *Dellided* |

| Motherboard | GIGABYTE GA-Z68X-UD3H-B3 Rev. 1.1 |

| Cooling | Thermaltake Water 3.0 Pro + Tt Riing12 x2 / Tt ThunderBlade / Gelid Slim 120UV fans |

| Memory | 16GB DRR3 Kingoston with Custom Tt spreaders + HyperX Fan |

| Video Card(s) | GeForce GTX 980 4GB Nvidia Sample |

| Storage | Crucial M4 SSD 64GB's / Seagate Barracuda 2TB / Seagate Barracuda 320GB's |

| Display(s) | 22" LG FLATRON 1920 x 1280p |

| Case | Thermaltake Commander G42 Window |

| Audio Device(s) | On-board Dolby 5.1+ Kingston HyperX Cloud 1 |

| Power Supply | Themaltake TR2 700W 80plus bronce & APC Pro backup 1000Va |

| Mouse | Tt eSports Level 10M Rev 1.0 Diamond Black & Tt Conkor "L" mouse pad |

| Keyboard | Tt eSports KNUCKER |

| Software | windows 10x64Pro |

| Benchmark Scores | well I've fried a 775' P4 12 years ago, that counts? |

agreed, but there may be also a correct mount or block seat that might do the rest of the great job sir,and I've found that the less compound, the better.

video was going great till he spread Coollab over the IHs, personally i just use and recomend coollab for delid porpuses, not for single use on proceesor's IHS,X-shape has proven to be the most reliable method with the best coverage from my experience thus far.

by way of illustration

Cisco's recommendation:

View attachment 77981

also its quite curious that he didnt tried Arctic Silver 5

Regards,

- Joined

- Apr 12, 2006

- Messages

- 29,714 (4.26/day)

| System Name | EVA-01 |

|---|---|

| Processor | Intel i7 13700K |

| Motherboard | Asus ROG Maximus Z690 HERO EVA Edition |

| Cooling | ASUS ROG Ryujin III 360 with Noctua Industrial Fans |

| Memory | PAtriot Viper Elite RGB 96GB @ 6000MHz. |

| Video Card(s) | Asus ROG Strix GeForce RTX 3090 24GB OC EVA Edition |

| Storage | Addlink S95 M.2 PCIe GEN 4x4 2TB |

| Display(s) | Asus ROG SWIFT OLED PG42UQ |

| Case | Thermaltake Core P3 TG |

| Audio Device(s) | Realtek on board > Sony Receiver > Cerwin Vegas |

| Power Supply | be quiet DARK POWER PRO 12 1500W |

| Mouse | ROG STRIX Impact Electro Punk |

| Keyboard | ROG STRIX Scope TKL Electro Punk |

| Software | Windows 11 |

This is the way I have always pasted my HDT coolers. Not my image, just used as reference.

- Joined

- Oct 12, 2008

- Messages

- 13,359 (2.20/day)

Some nice examples here --> Application on HDT Coolers

It may be just me... I see to many areas for the possibility of air being trapped.

It may be just me... I see to many areas for the possibility of air being trapped.

- Joined

- Oct 29, 2012

- Messages

- 842 (0.18/day)

- Location

- Germany

| System Name | Perf/price king /w focus on low noise and TDP |

|---|---|

| Processor | Intel Xeon E3-1230 v2 |

| Motherboard | Gigabyte GA-B75M-D3H |

| Cooling | Thermalright HR-02 Macho Rev.A (BW) |

| Memory | 16GB Corsair Vengeance LP Black |

| Video Card(s) | Gigabyte GTX 670 OC |

| Storage | 525GB Crucial MX300 & 256GB Samsung 830 Series |

| Display(s) | Home: LG 29UB65-P & Work: LG 34UB88-B |

| Case | Fractal Design Arc Mini |

| Audio Device(s) | Asus Xonar Essence STX /w Sennheiser HD 598 |

| Power Supply | be quiet! Straight Power CM E9 80+ Gold 480W |

| Mouse | Roccat Kone XTD optical |

| Keyboard | SteelSeries Apex M500 |

| Software | Win10 |

I was curious and actually tried this method several times today at work. Was very pleased with the results and I can confirm that no air will be trapped, since the X will push the small peas outwards. Will have to admit that I used too much thermal paste throughout the first 2-3 attempts though.It may be just me... I see to many areas for the possibility of air being trapped.

Last edited:

- Joined

- Apr 12, 2006

- Messages

- 29,714 (4.26/day)

| System Name | EVA-01 |

|---|---|

| Processor | Intel i7 13700K |

| Motherboard | Asus ROG Maximus Z690 HERO EVA Edition |

| Cooling | ASUS ROG Ryujin III 360 with Noctua Industrial Fans |

| Memory | PAtriot Viper Elite RGB 96GB @ 6000MHz. |

| Video Card(s) | Asus ROG Strix GeForce RTX 3090 24GB OC EVA Edition |

| Storage | Addlink S95 M.2 PCIe GEN 4x4 2TB |

| Display(s) | Asus ROG SWIFT OLED PG42UQ |

| Case | Thermaltake Core P3 TG |

| Audio Device(s) | Realtek on board > Sony Receiver > Cerwin Vegas |

| Power Supply | be quiet DARK POWER PRO 12 1500W |

| Mouse | ROG STRIX Impact Electro Punk |

| Keyboard | ROG STRIX Scope TKL Electro Punk |

| Software | Windows 11 |

Normally, with solid base coolers. I use a five dot method. Have used this for years on many coolers and have great success with an even spread. Much like the example from Dethroy, but it uses much less paste. Would also tend to work with HDT coolers, as the paste is where the pipes are, rather than trying to set it in the middle and spread that glob outwards. Again, not my image, just an example I found.

Norton

Moderator - Returning from the Darkness

- Joined

- Dec 21, 2011

- Messages

- 14,104 (2.88/day)

- Location

- Northeast USA

| System Name | Main PC- Gamer- Main Cruncher/Folder and too many crunching/folding rigs |

|---|---|

| Processor | Ryzen 5900X- Ryzen 5950X- Ryzen 3950X and etc... |

| Motherboard | Asrock X570 Extreme4- MSI X570S Tomahawk MAX WiFi- MSI B450M Bazooka Max and etc... |

| Cooling | Noctua NH-U14S (dual fan)- EK 360 AIO with push/pull fans- Corsair H115i RGB Pro XT and etc... |

| Memory | 2x16GB GSkill FlareX 3200/c14- 4x8GB Corsair Vengeance 3600/c16- 2x16GB Team 3600/c18 and etc.. |

| Video Card(s) | MSI Gaming RX 6800- Asus RTX 3070 TUF OC- MSI Ventus GTX 1660Ti and etc... |

| Storage | Main PC (1TB WD SN850- 2TB PNY CS 3040- 2TB Seagate Firecuda) and etc... |

| Display(s) | Main PC (2x24" Dell UltraSharp U2414H) |

| Case | Phanteks P600s- Seasonic Q704- Fractal Meshify C and etc... |

| Audio Device(s) | Logitech Z625 THX 2.1 speakers |

| Power Supply | EVGA 750 G3- SeaSonic DGC 750- EVGA P2 850 and etc... |

| Mouse | G300s |

| Keyboard | Corsair K65 |

| VR HMD | N/A |

| Software | Windows 10 Pro or Ubuntu |

| Benchmark Scores | Why sit on the Bench when you can get in the game and Crunch!!! |

I use the thin line method on HDT coolers- haven't had a problem with any installs that I've done

Like this (image from a TweakTown review):

http://www.tweaktown.com/reviews/47...ht_hawk_edition_cpu_cooler_review/index6.html

Like this (image from a TweakTown review):

http://www.tweaktown.com/reviews/47...ht_hawk_edition_cpu_cooler_review/index6.html

erocker

*

- Joined

- Jul 19, 2006

- Messages

- 43,629 (6.34/day)

| Processor | AMD Ryzen 7 7800X3D |

|---|---|

| Motherboard | ASUS TUF x670e-Plus Wifi |

| Cooling | EK AIO 360. Phantek T30 fans. |

| Memory | 64GB G.Skill 6000Mhz |

| Video Card(s) | Asus RTX 4090 |

| Storage | WD/Samsung m.2's |

| Display(s) | LG C2 Evo OLED 42" |

| Case | Fractal Design North |

| Audio Device(s) | Topping E70 DAC, SMSL SP200 Amp, Adam Audio T5V's, Hifiman Sundara's. |

| Power Supply | FSP Hydro Ti PRO 1000W |

| Mouse | Razer Basilisk V3 Pro |

| Keyboard | Epomaker 84 key |

| Software | Windows 11 Pro |

X-shape has proven to be the most reliable method with the best coverage from my experience thus far.

by way of illustration

Cisco's recommendation:

View attachment 77981

This is what I use. Before that, if I'm using an exposed heatpipe cooler I will "tint" them as @peche mentioned above, to fill in the creases/gaps between the pipes.

- Joined

- Apr 12, 2006

- Messages

- 29,714 (4.26/day)

| System Name | EVA-01 |

|---|---|

| Processor | Intel i7 13700K |

| Motherboard | Asus ROG Maximus Z690 HERO EVA Edition |

| Cooling | ASUS ROG Ryujin III 360 with Noctua Industrial Fans |

| Memory | PAtriot Viper Elite RGB 96GB @ 6000MHz. |

| Video Card(s) | Asus ROG Strix GeForce RTX 3090 24GB OC EVA Edition |

| Storage | Addlink S95 M.2 PCIe GEN 4x4 2TB |

| Display(s) | Asus ROG SWIFT OLED PG42UQ |

| Case | Thermaltake Core P3 TG |

| Audio Device(s) | Realtek on board > Sony Receiver > Cerwin Vegas |

| Power Supply | be quiet DARK POWER PRO 12 1500W |

| Mouse | ROG STRIX Impact Electro Punk |

| Keyboard | ROG STRIX Scope TKL Electro Punk |

| Software | Windows 11 |

I use the thin line method on HDT coolers- haven't had a problem with any installs that I've done

Like this (image from a TweakTown review):

http://www.tweaktown.com/reviews/47...ht_hawk_edition_cpu_cooler_review/index6.html

Someone dug deep to find that image!

Norton

Moderator - Returning from the Darkness

- Joined

- Dec 21, 2011

- Messages

- 14,104 (2.88/day)

- Location

- Northeast USA

| System Name | Main PC- Gamer- Main Cruncher/Folder and too many crunching/folding rigs |

|---|---|

| Processor | Ryzen 5900X- Ryzen 5950X- Ryzen 3950X and etc... |

| Motherboard | Asrock X570 Extreme4- MSI X570S Tomahawk MAX WiFi- MSI B450M Bazooka Max and etc... |

| Cooling | Noctua NH-U14S (dual fan)- EK 360 AIO with push/pull fans- Corsair H115i RGB Pro XT and etc... |

| Memory | 2x16GB GSkill FlareX 3200/c14- 4x8GB Corsair Vengeance 3600/c16- 2x16GB Team 3600/c18 and etc.. |

| Video Card(s) | MSI Gaming RX 6800- Asus RTX 3070 TUF OC- MSI Ventus GTX 1660Ti and etc... |

| Storage | Main PC (1TB WD SN850- 2TB PNY CS 3040- 2TB Seagate Firecuda) and etc... |

| Display(s) | Main PC (2x24" Dell UltraSharp U2414H) |

| Case | Phanteks P600s- Seasonic Q704- Fractal Meshify C and etc... |

| Audio Device(s) | Logitech Z625 THX 2.1 speakers |

| Power Supply | EVGA 750 G3- SeaSonic DGC 750- EVGA P2 850 and etc... |

| Mouse | G300s |

| Keyboard | Corsair K65 |

| VR HMD | N/A |

| Software | Windows 10 Pro or Ubuntu |

| Benchmark Scores | Why sit on the Bench when you can get in the game and Crunch!!! |

Wasn't hard considering the cooler in that picture is 3 feet away from me in my main rig...Someone dug deep to find that image!

peche

Thermaltake fanboy

- Joined

- Nov 7, 2014

- Messages

- 6,709 (1.74/day)

- Location

- San Jose, Costa Rica

| System Name | Athenna |

|---|---|

| Processor | intel i7 3770 *Dellided* |

| Motherboard | GIGABYTE GA-Z68X-UD3H-B3 Rev. 1.1 |

| Cooling | Thermaltake Water 3.0 Pro + Tt Riing12 x2 / Tt ThunderBlade / Gelid Slim 120UV fans |

| Memory | 16GB DRR3 Kingoston with Custom Tt spreaders + HyperX Fan |

| Video Card(s) | GeForce GTX 980 4GB Nvidia Sample |

| Storage | Crucial M4 SSD 64GB's / Seagate Barracuda 2TB / Seagate Barracuda 320GB's |

| Display(s) | 22" LG FLATRON 1920 x 1280p |

| Case | Thermaltake Commander G42 Window |

| Audio Device(s) | On-board Dolby 5.1+ Kingston HyperX Cloud 1 |

| Power Supply | Themaltake TR2 700W 80plus bronce & APC Pro backup 1000Va |

| Mouse | Tt eSports Level 10M Rev 1.0 Diamond Black & Tt Conkor "L" mouse pad |

| Keyboard | Tt eSports KNUCKER |

| Software | windows 10x64Pro |

| Benchmark Scores | well I've fried a 775' P4 12 years ago, that counts? |

ill perform a little tint over there.. i dont trust the space between every heatpipe and cooler base...I use the thin line method on HDT coolers- haven't had a problem with any installs that I've done

Like this (image from a TweakTown review):

http://www.tweaktown.com/reviews/47...ht_hawk_edition_cpu_cooler_review/index6.html

- Joined

- Apr 12, 2006

- Messages

- 29,714 (4.26/day)

| System Name | EVA-01 |

|---|---|

| Processor | Intel i7 13700K |

| Motherboard | Asus ROG Maximus Z690 HERO EVA Edition |

| Cooling | ASUS ROG Ryujin III 360 with Noctua Industrial Fans |

| Memory | PAtriot Viper Elite RGB 96GB @ 6000MHz. |

| Video Card(s) | Asus ROG Strix GeForce RTX 3090 24GB OC EVA Edition |

| Storage | Addlink S95 M.2 PCIe GEN 4x4 2TB |

| Display(s) | Asus ROG SWIFT OLED PG42UQ |

| Case | Thermaltake Core P3 TG |

| Audio Device(s) | Realtek on board > Sony Receiver > Cerwin Vegas |

| Power Supply | be quiet DARK POWER PRO 12 1500W |

| Mouse | ROG STRIX Impact Electro Punk |

| Keyboard | ROG STRIX Scope TKL Electro Punk |

| Software | Windows 11 |

ill perform a little tint over there.. i dont trust the space between every heatpipe and cooler base...

The aluminum plate/base of such coolers do very little to cool the CPU anyways. You want the paste on the copper bits.

peche

Thermaltake fanboy

- Joined

- Nov 7, 2014

- Messages

- 6,709 (1.74/day)

- Location

- San Jose, Costa Rica

| System Name | Athenna |

|---|---|

| Processor | intel i7 3770 *Dellided* |

| Motherboard | GIGABYTE GA-Z68X-UD3H-B3 Rev. 1.1 |

| Cooling | Thermaltake Water 3.0 Pro + Tt Riing12 x2 / Tt ThunderBlade / Gelid Slim 120UV fans |

| Memory | 16GB DRR3 Kingoston with Custom Tt spreaders + HyperX Fan |

| Video Card(s) | GeForce GTX 980 4GB Nvidia Sample |

| Storage | Crucial M4 SSD 64GB's / Seagate Barracuda 2TB / Seagate Barracuda 320GB's |

| Display(s) | 22" LG FLATRON 1920 x 1280p |

| Case | Thermaltake Commander G42 Window |

| Audio Device(s) | On-board Dolby 5.1+ Kingston HyperX Cloud 1 |

| Power Supply | Themaltake TR2 700W 80plus bronce & APC Pro backup 1000Va |

| Mouse | Tt eSports Level 10M Rev 1.0 Diamond Black & Tt Conkor "L" mouse pad |

| Keyboard | Tt eSports KNUCKER |

| Software | windows 10x64Pro |

| Benchmark Scores | well I've fried a 775' P4 12 years ago, that counts? |

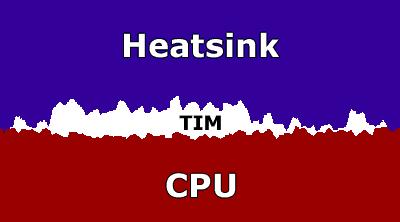

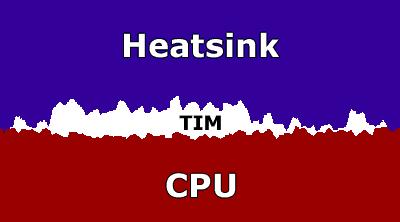

not just over the cooper, check this elemental fact:The aluminum plate/base of such coolers do very little to cool the CPU anyways. You want the paste on the copper bits.

tim is used to fill al the gaps between cpu and heatsink right?

Since the heatpipes are little bit exposed and not joint togheter there is a space, that might be tinted or filled for trying to get a flat surface for optional contact or heat exchange between both surfaces, helped by TIM

Regards,

- Joined

- Apr 12, 2006

- Messages

- 29,714 (4.26/day)

| System Name | EVA-01 |

|---|---|

| Processor | Intel i7 13700K |

| Motherboard | Asus ROG Maximus Z690 HERO EVA Edition |

| Cooling | ASUS ROG Ryujin III 360 with Noctua Industrial Fans |

| Memory | PAtriot Viper Elite RGB 96GB @ 6000MHz. |

| Video Card(s) | Asus ROG Strix GeForce RTX 3090 24GB OC EVA Edition |

| Storage | Addlink S95 M.2 PCIe GEN 4x4 2TB |

| Display(s) | Asus ROG SWIFT OLED PG42UQ |

| Case | Thermaltake Core P3 TG |

| Audio Device(s) | Realtek on board > Sony Receiver > Cerwin Vegas |

| Power Supply | be quiet DARK POWER PRO 12 1500W |

| Mouse | ROG STRIX Impact Electro Punk |

| Keyboard | ROG STRIX Scope TKL Electro Punk |

| Software | Windows 11 |

not just over the cooper, check this elemental fact:

tim is used to fill al the gaps between cpu and heatsink right?

Since the heatpipes are little bit exposed and not joint togheter there is a space, that might be tinted or filled for trying to get a flat surface for optional contact or heat exchange between both surfaces, helped by TIM

Regards,

That image is for a solid base cooler. I am simply stating this. When using an HDT cooler, even feeling the two components, the aluminum does not warm up like the pipes do near the base. With such little contact for the Aluminum to make with the CPU IHS, it does very little for cooling the CPU. However, the wider copper parts take on the majority of the heat dissipated into the base of the cooler, and is where it is important to get the TIM. If you look closely at the image that Norton added above, you will see that Xigmatek did not even use TIM between the pipes and the aluminum spacer plate. This means thermal transfer from the pipes to the base is very limited. Some companies will paste this surface during assembly, and you will see a bit of the TIM squeezing out. Then again, when you use the finger test or an IR thermometer to get readings of the spacer plate versus the heat pipes, it is plainly obvious that the aluminum does very little for overall results. To each their own though! Thing is though, when using a line on each pipe, the paste will fill the gaps, I can take images and prove to you what I mean if you would like to see this in action rather than just words.

- Joined

- Apr 30, 2006

- Messages

- 1,181 (0.17/day)

| Processor | 7900 |

|---|---|

| Motherboard | Rampage Apex |

| Cooling | H115i |

| Memory | 64GB TridentZ 3200 14-14-14-34-1T |

| Video Card(s) | Fury X |

| Case | Corsair 740 |

| Audio Device(s) | 8ch LPCM via HDMI to Yamaha Z7 Receiver |

| Power Supply | Corsair AX860 |

| Mouse | G903 |

| Keyboard | G810 |

| Software | 8.1 x64 |

I need to pull my cooler off and see how well the paste has spread.

Also, doesnt anyone use AS5 anymore? Maybe I need to get a better paste...

Also, doesnt anyone use AS5 anymore? Maybe I need to get a better paste...