- Joined

- Jan 30, 2016

- Messages

- 27 (0.01/day)

- Location

- Alberta, Canada

Hey everyone,

I've decided, now that I'm finally done first semester and exams are over, I would try something new. The table I'm currently using I've owned for several years, and I'm starting to get sick of it, it's inefficient for my needs, it doesn't fit with the rest of my room, and it's not cool enough!!! So what I have for you today is something I've been working on for quite some time now, with several prototypes and re-edits. This table has been designed to fit perfectly in the space I want to, and hopefully will make things look a lot nicer. This is really my first build to this size, so I hope you guys enjoy and if you have any questions or suggestions, feel free to join me!

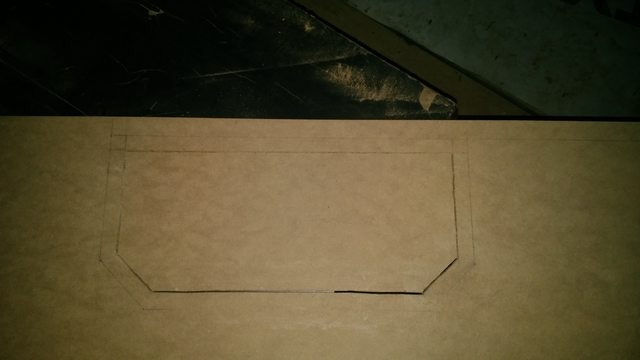

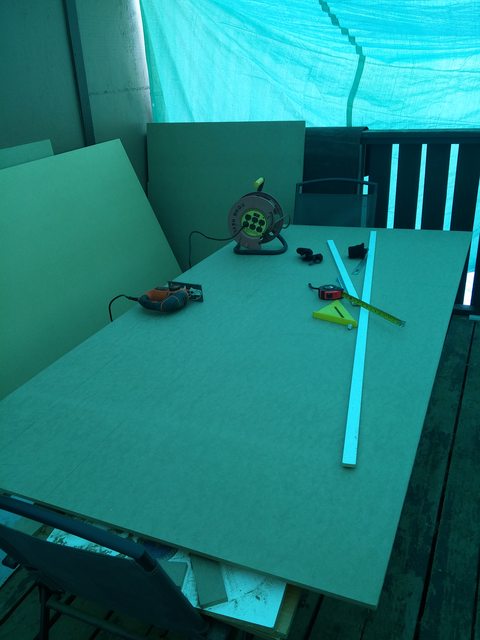

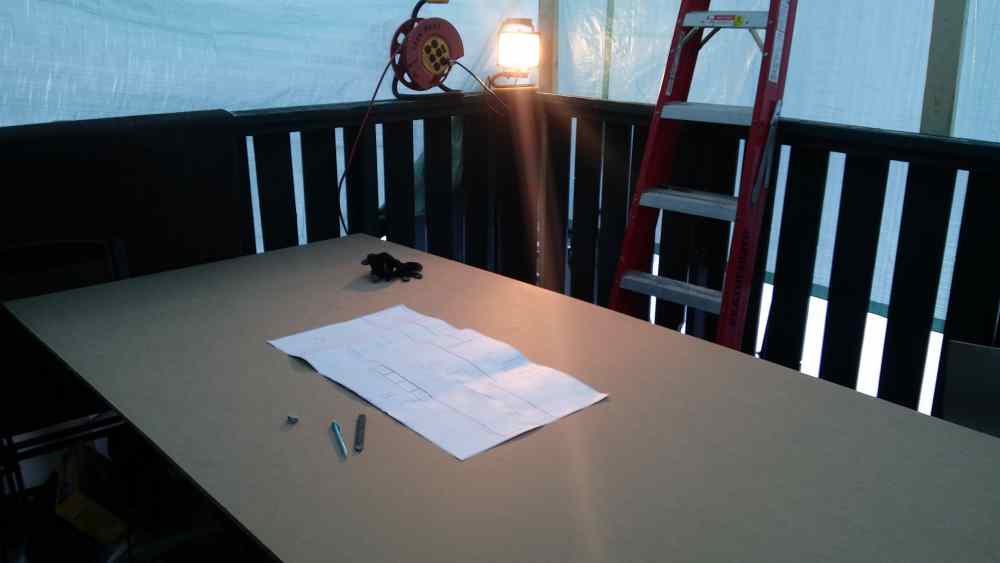

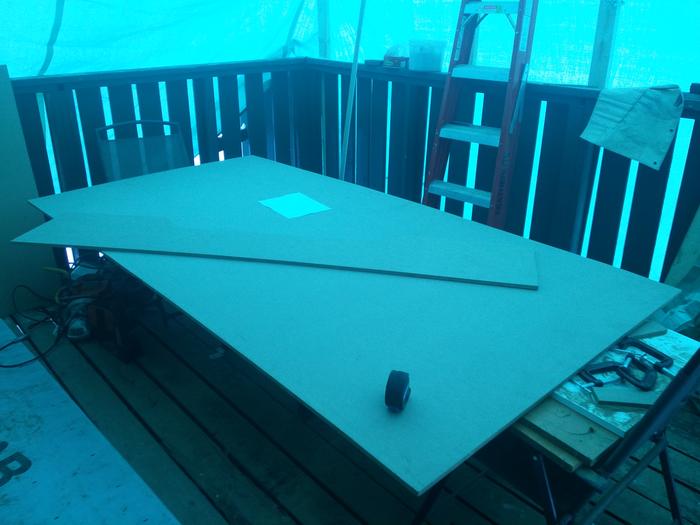

Current work area

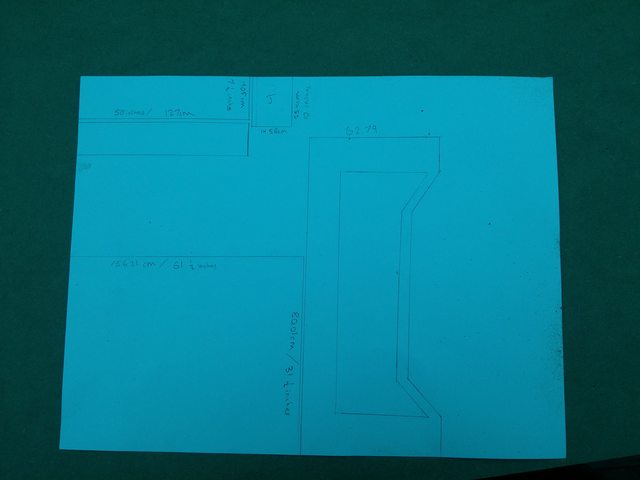

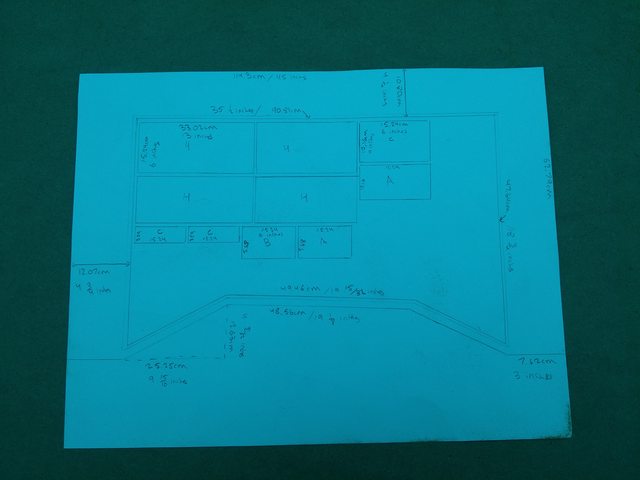

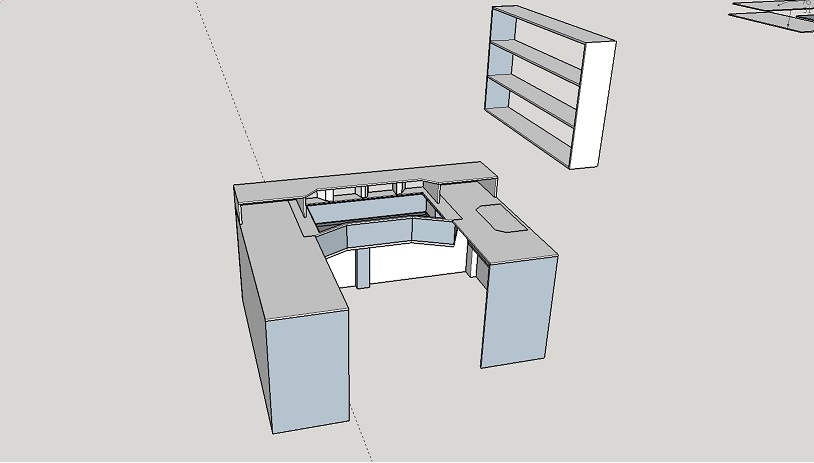

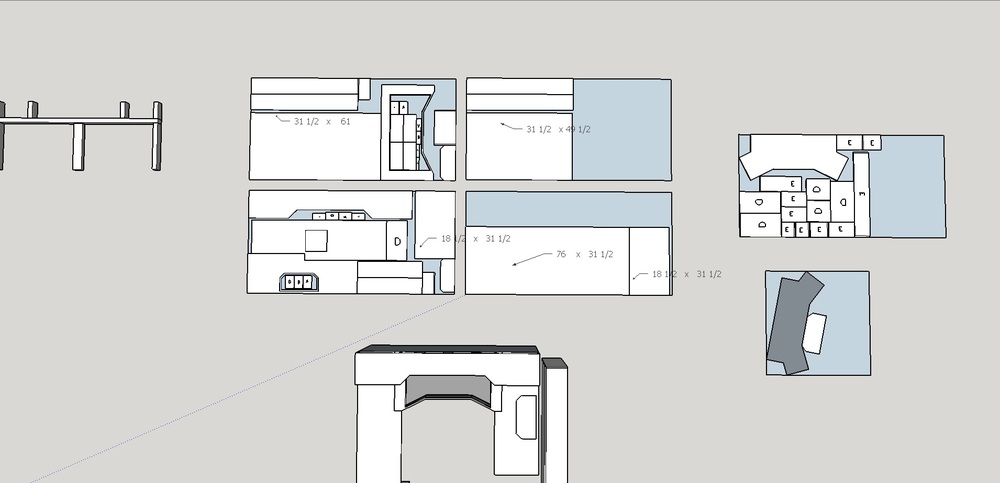

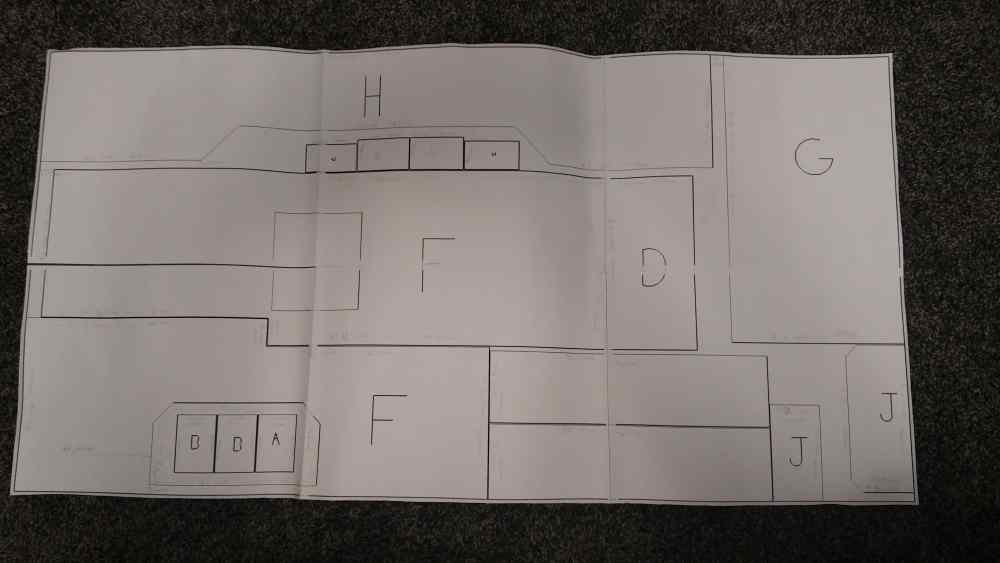

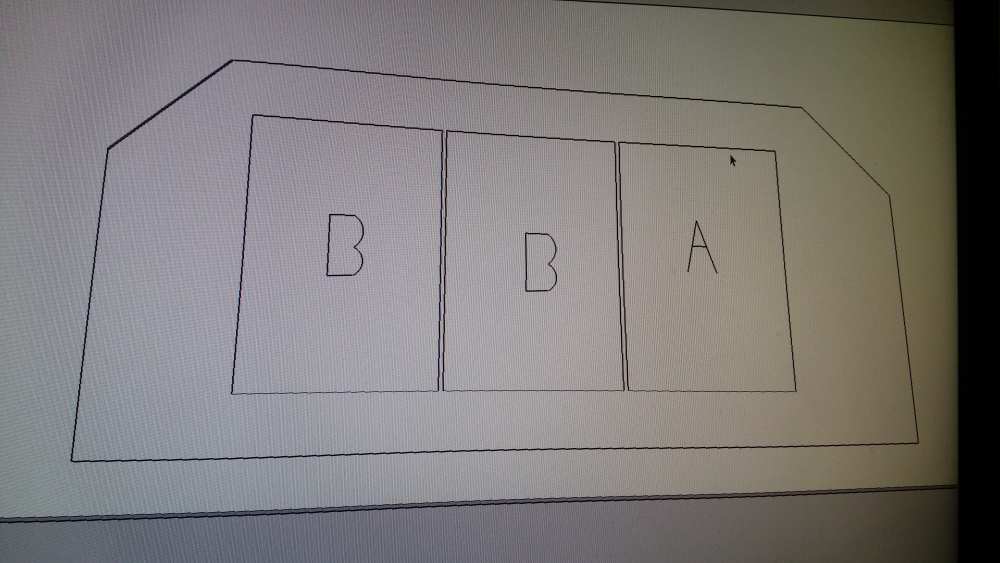

The completed station

The table will not be going in the same place where it is now. I would show you where it would go, but it's kind of a mess right now

I've decided, now that I'm finally done first semester and exams are over, I would try something new. The table I'm currently using I've owned for several years, and I'm starting to get sick of it, it's inefficient for my needs, it doesn't fit with the rest of my room, and it's not cool enough!!! So what I have for you today is something I've been working on for quite some time now, with several prototypes and re-edits. This table has been designed to fit perfectly in the space I want to, and hopefully will make things look a lot nicer. This is really my first build to this size, so I hope you guys enjoy and if you have any questions or suggestions, feel free to join me!

Current work area

The completed station

The table will not be going in the same place where it is now. I would show you where it would go, but it's kind of a mess right now

.

.

.

.