- Joined

- Nov 1, 2008

- Messages

- 4,213 (0.70/day)

- Location

- Vietnam

| System Name | Gaming System / HTPC-Server |

|---|---|

| Processor | i7 8700K (@4.8 Ghz All-Core) / R7 5900X |

| Motherboard | Z370 Aorus Ultra Gaming / MSI B450 Mortar Max |

| Cooling | CM ML360 / CM ML240L |

| Memory | 16Gb Hynix @3200 MHz / 16Gb Hynix @3000Mhz |

| Video Card(s) | Zotac 3080 / Colorful 1060 |

| Storage | 750G MX300 + 2x500G NVMe / 40Tb Reds + 1Tb WD Blue NVMe |

| Display(s) | LG 27GN800-B 27'' 2K 144Hz / Sony TV |

| Case | Xigmatek Aquarius Plus / Corsair Air 240 |

| Audio Device(s) | On Board Realtek |

| Power Supply | Super Flower Leadex III Gold 750W / Andyson TX-700 Platinum |

| Mouse | Logitech G502 Hero / K400+ |

| Keyboard | Wooting Two / K400+ |

| Software | Windows 10 x64 |

| Benchmark Scores | Cinebench R15 = 1542 3D Mark Timespy = 9758 |

This thread is a continuation of the following: https://www.techpowerup.com/forums/threads/lapping-sanding-ihs-and-waterblock.258162/#post-4096571

For TLDR, scroll to bottom.

So after lapping the IHS on my 8700k and waterblock, I'd decided that I really wanted to delid too as the temperatures weren't quite what I wanted.

I ordered my LM Ultra, as well as a delidding kit from AliExpress.

My LM came within a couple of days, but even with the fastest shipping method, the delidding kit would take a least a couple of weeks

Being the impatient SOB I am, I also bought a $.5 pack of thin Gillette razors and made the decision that I was going to 'go manual'.

Now most people reading this will be thinking this was where I went wrong and in 99% of stories, you'd be correct. However, buying the razors might have actually saved my CPU.

I've had the 8700k for about a year now, after upgrading from an 8600k. I sold the 8600k locally for a little bit more than what my current CPU cost. My 8700k wasn't new, and I'd gotten a good deal on it from the forums. When I bought it, I'd thought there might be something wrong with it, but made a gamble, received it quickly, slapped it in my PC and saw that it was working fine. The temps on it were a little high, but nothing unusual for this chip so just assumed I'd not been lucky on the silicone lottery and perhaps that's why the seller was selling it relatively cheap.

Well, today, I discovered the reason it was cheap.

I gently went around the IHS with the thin razor, but a couple of the corners were giving me difficulty. I had a closer look at the CPU and noticed what looked to be white superglue on one of the corners. Barely noticeable.

Damn! It looked like someone had already had a go at delidding this processor and it hadn't gone to plan. I take out a bit of acetone and dip a q-tip in it to try and rub off some of the glue before having a last go with the razor.

A little elbow grease and a heart-wrenching quiet 'crack' afterwards and the IHS pops right off. I was planning on soaking it in acetone after this final, gentle attempt and the 'crack' took me by surprise.

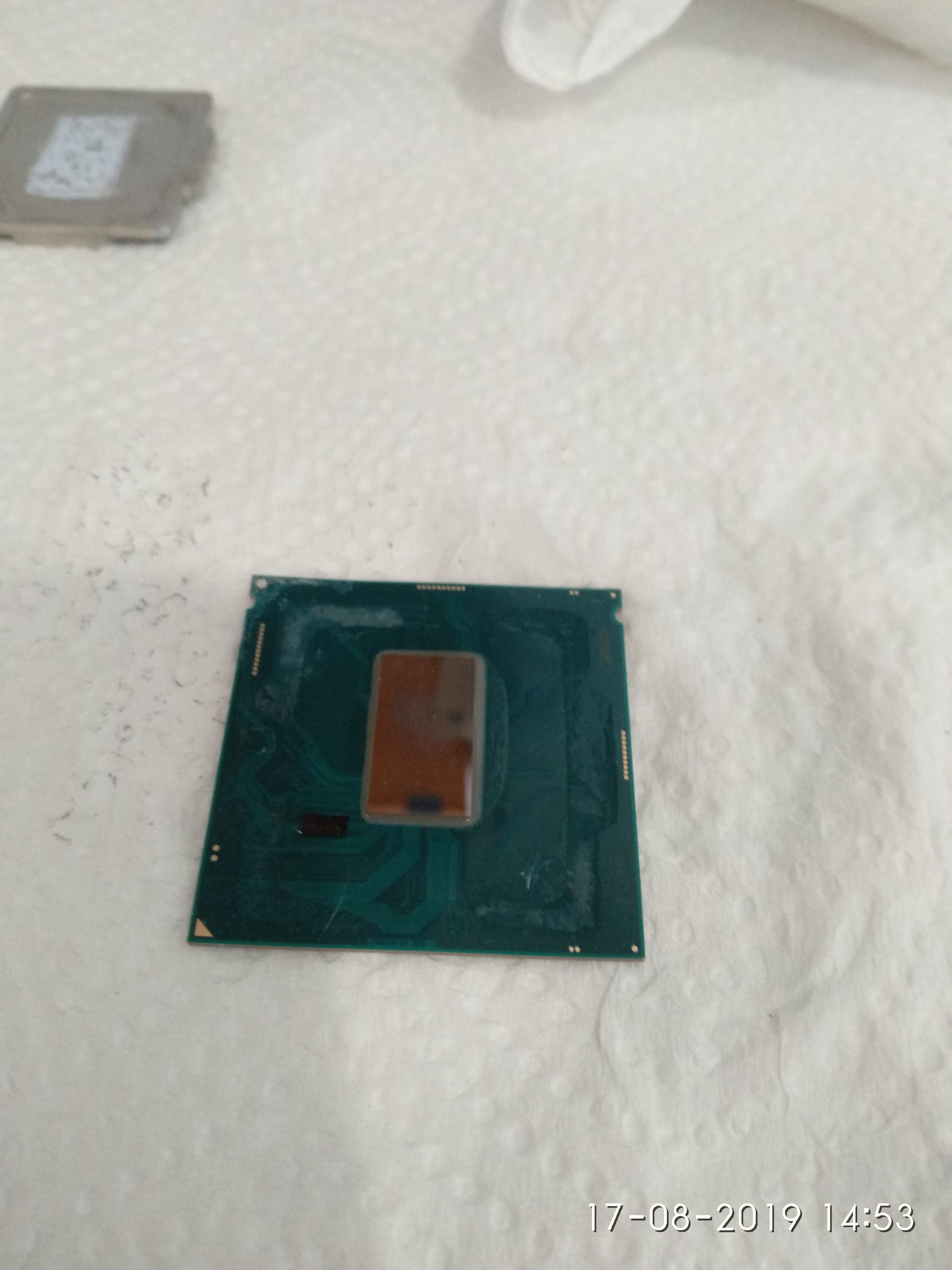

This is what I find:

Someone has gone to the trouble of delidding the processor, butting a bit of TIM on there and then trying to superglue it back on, without removing the sealant!

No wonder the temps were so bad on this chip! If you look closely you can see that the Glue is sitting on top of the sealant which has soaked through forming a hard, crusty layer.

I try to remove this with my fingernail, to no avail. With the CPU in this state, there is little point trying to apply LM and resealing it so I need to find a way to get that glue off.

Acetone it is - The nail polish remover type, not industrial strength.

I soak it for 5 minutes - Very little comes off

I soak it for another 10 minutes - A little more comes off, but the glue seems to have bonded and reacted with the sealant that it's formed a new compound which is a lot more hardy than regular glue.

either that, or the nail polish remover I am using is just too weak in concentration.

At this point, I'm a little worried whether the CPU will boot any more and decide to apply the LM and give it a shot.

My original plan was to reseal the CPU with some silicone sealant, but at this point i'm not even sure it'll work so decide to have the IHS 'free-floating' and lock it down with the CPU retention bracket.

I put everything back together, apply a healthy dose of TIM to my AIO and screw everything down tight.

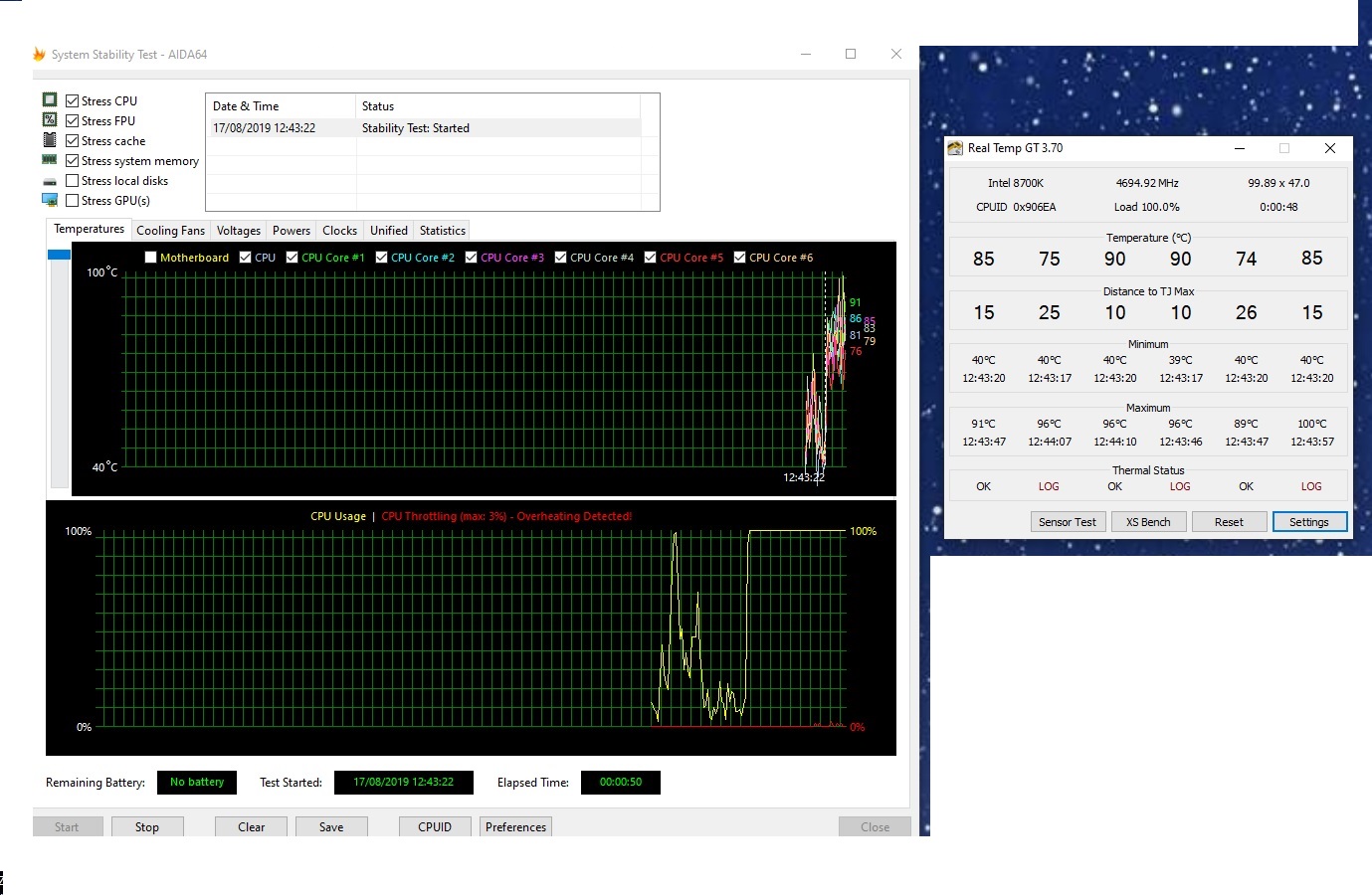

Moment of truth . . . It boots! success I haven't killed my CPU. That's a win in my book. But, what are the temps?

Worse than they were in the first place. Damn! I need to remove some more of that glue-sealant shit on the cpu so disassemble everything. Take out the CPU and clean it up then soak it in acetone again. This time for another 20 mins.

I take it out again and try to clean up more of the glue. A little comes off, but there is still a stubborn layer, around 0.2 mm thick on two of the corners. . . What is this shit made of?

Sod it. Time to risk it all. I decide to soak it in acetone for 1-2 hrs while I go take a nap. When I get back, I grab myself a coffee before heading outside to the acetone soaked CPU hoping that the PCB hasn't started to melt yet.

Take it out and voila! A good chunk of the glue comes off. After another 10 minute soak, I've gotten the final corner more or less clean.

There are still some stubborn areas, but I have a feeling that I'd only be able to remove them with an angle-grinder and really need to test to see whether the CPU will still work.

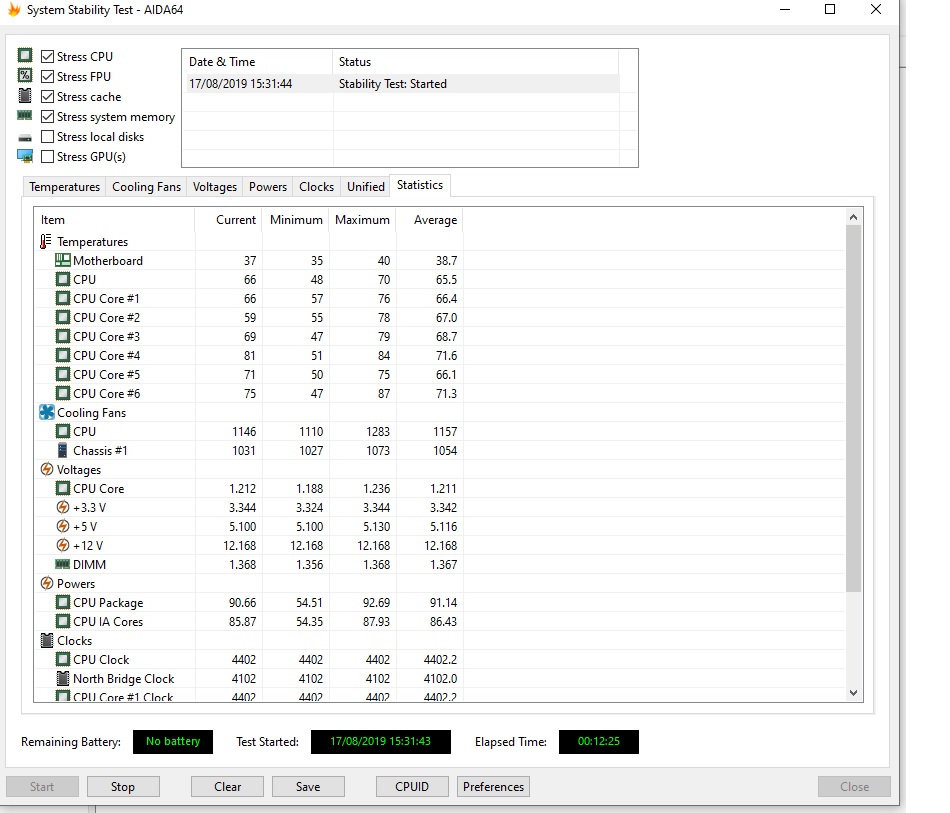

I reapply the CPU with LM and put everything back in. Damn . . . temps are still high! Now all the guides say to use LM very sparingly and I have, but it's really hard to judge how much is actually on the die with the die being reflective and the LM also being reflective. I saw that there was good contact between the IHS and die before reapplying: each end of the IHS would lift up slightly when pressing on the other.

Time for a little more LM. A bigger blob this time on both the IHS and die along with a bit of electrical tape on the 4 contacts next to the die, just in case. Time to get my PC to boot.

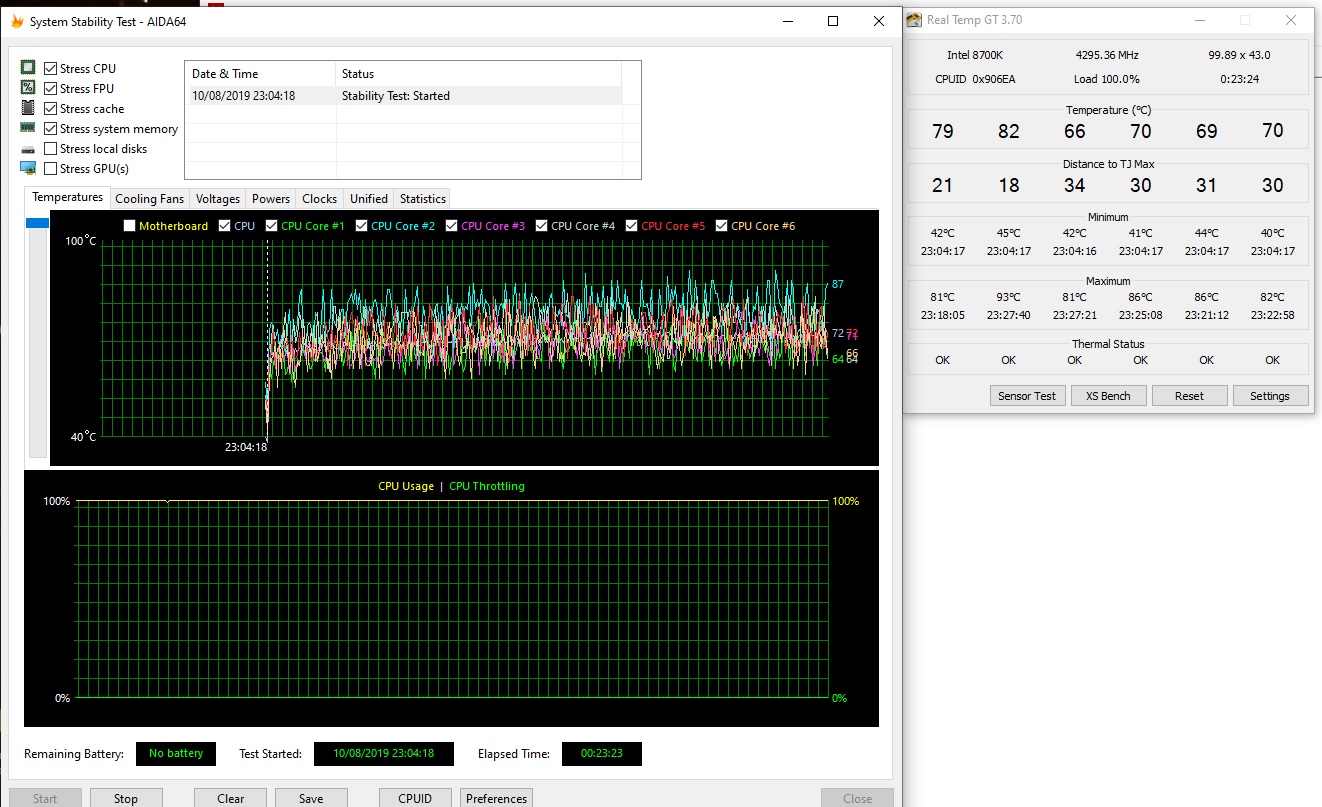

Success!! Finally some good temps.

There are still a couple of cores that are getting quite hot, but this is a win in my book and within expectations for delidding.

I'm not sure whether I will go back at a later date to try reapplying the LM a little better (or adding more) but, this will do for now!

TLDR: Delidded my CPU without knowing someone had done it (badly) before. Got lucky by using a razor, instead of a delidding kit which could have ripped through the PCB and (semi-)successfully cleaned it all up to relid again properly. Not bad for my first attempt at this!

For TLDR, scroll to bottom.

So after lapping the IHS on my 8700k and waterblock, I'd decided that I really wanted to delid too as the temperatures weren't quite what I wanted.

I ordered my LM Ultra, as well as a delidding kit from AliExpress.

My LM came within a couple of days, but even with the fastest shipping method, the delidding kit would take a least a couple of weeks

Being the impatient SOB I am, I also bought a $.5 pack of thin Gillette razors and made the decision that I was going to 'go manual'.

Now most people reading this will be thinking this was where I went wrong and in 99% of stories, you'd be correct. However, buying the razors might have actually saved my CPU.

I've had the 8700k for about a year now, after upgrading from an 8600k. I sold the 8600k locally for a little bit more than what my current CPU cost. My 8700k wasn't new, and I'd gotten a good deal on it from the forums. When I bought it, I'd thought there might be something wrong with it, but made a gamble, received it quickly, slapped it in my PC and saw that it was working fine. The temps on it were a little high, but nothing unusual for this chip so just assumed I'd not been lucky on the silicone lottery and perhaps that's why the seller was selling it relatively cheap.

Well, today, I discovered the reason it was cheap.

I gently went around the IHS with the thin razor, but a couple of the corners were giving me difficulty. I had a closer look at the CPU and noticed what looked to be white superglue on one of the corners. Barely noticeable.

Damn! It looked like someone had already had a go at delidding this processor and it hadn't gone to plan. I take out a bit of acetone and dip a q-tip in it to try and rub off some of the glue before having a last go with the razor.

A little elbow grease and a heart-wrenching quiet 'crack' afterwards and the IHS pops right off. I was planning on soaking it in acetone after this final, gentle attempt and the 'crack' took me by surprise.

This is what I find:

Someone has gone to the trouble of delidding the processor, butting a bit of TIM on there and then trying to superglue it back on, without removing the sealant!

No wonder the temps were so bad on this chip! If you look closely you can see that the Glue is sitting on top of the sealant which has soaked through forming a hard, crusty layer.

I try to remove this with my fingernail, to no avail. With the CPU in this state, there is little point trying to apply LM and resealing it so I need to find a way to get that glue off.

Acetone it is - The nail polish remover type, not industrial strength.

I soak it for 5 minutes - Very little comes off

I soak it for another 10 minutes - A little more comes off, but the glue seems to have bonded and reacted with the sealant that it's formed a new compound which is a lot more hardy than regular glue.

either that, or the nail polish remover I am using is just too weak in concentration.

At this point, I'm a little worried whether the CPU will boot any more and decide to apply the LM and give it a shot.

My original plan was to reseal the CPU with some silicone sealant, but at this point i'm not even sure it'll work so decide to have the IHS 'free-floating' and lock it down with the CPU retention bracket.

I put everything back together, apply a healthy dose of TIM to my AIO and screw everything down tight.

Moment of truth . . . It boots! success I haven't killed my CPU. That's a win in my book. But, what are the temps?

Worse than they were in the first place. Damn! I need to remove some more of that glue-sealant shit on the cpu so disassemble everything. Take out the CPU and clean it up then soak it in acetone again. This time for another 20 mins.

I take it out again and try to clean up more of the glue. A little comes off, but there is still a stubborn layer, around 0.2 mm thick on two of the corners. . . What is this shit made of?

Sod it. Time to risk it all. I decide to soak it in acetone for 1-2 hrs while I go take a nap. When I get back, I grab myself a coffee before heading outside to the acetone soaked CPU hoping that the PCB hasn't started to melt yet.

Take it out and voila! A good chunk of the glue comes off. After another 10 minute soak, I've gotten the final corner more or less clean.

There are still some stubborn areas, but I have a feeling that I'd only be able to remove them with an angle-grinder and really need to test to see whether the CPU will still work.

I reapply the CPU with LM and put everything back in. Damn . . . temps are still high! Now all the guides say to use LM very sparingly and I have, but it's really hard to judge how much is actually on the die with the die being reflective and the LM also being reflective. I saw that there was good contact between the IHS and die before reapplying: each end of the IHS would lift up slightly when pressing on the other.

Time for a little more LM. A bigger blob this time on both the IHS and die along with a bit of electrical tape on the 4 contacts next to the die, just in case. Time to get my PC to boot.

Success!! Finally some good temps.

There are still a couple of cores that are getting quite hot, but this is a win in my book and within expectations for delidding.

I'm not sure whether I will go back at a later date to try reapplying the LM a little better (or adding more) but, this will do for now!

TLDR: Delidded my CPU without knowing someone had done it (badly) before. Got lucky by using a razor, instead of a delidding kit which could have ripped through the PCB and (semi-)successfully cleaned it all up to relid again properly. Not bad for my first attempt at this!

Attachments

Last edited:

).

).

(i have a wall of gfx / mobo's alot of them still work)

(i have a wall of gfx / mobo's alot of them still work) very much enjoyed it and im sure we are all curious what the price on the cpu was

very much enjoyed it and im sure we are all curious what the price on the cpu was