Murderator

New Member

- Joined

- Nov 14, 2017

- Messages

- 7 (0.00/day)

- Location

- Indonesia

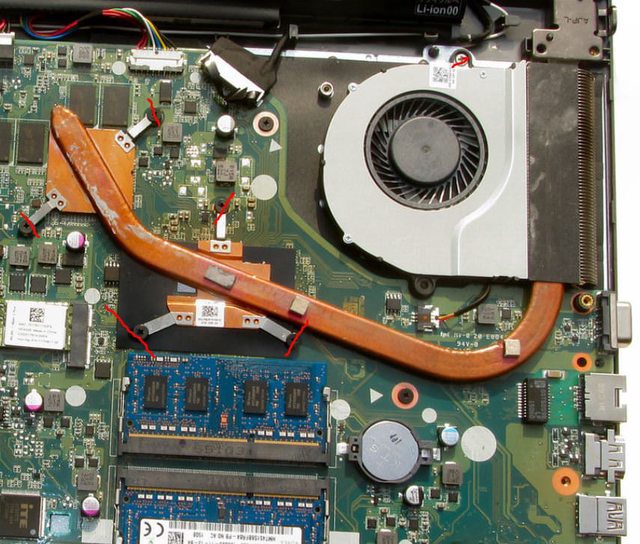

So my notebook have one screw on GPU heatsink that just won't comes out. It's head is just won't grip to any screwdriver anymore. I've tried glue method, no luck.

Is it safe to make a new thread/grip for a minus screwdriver, with a metal cutting saw?

will it damage the chip?

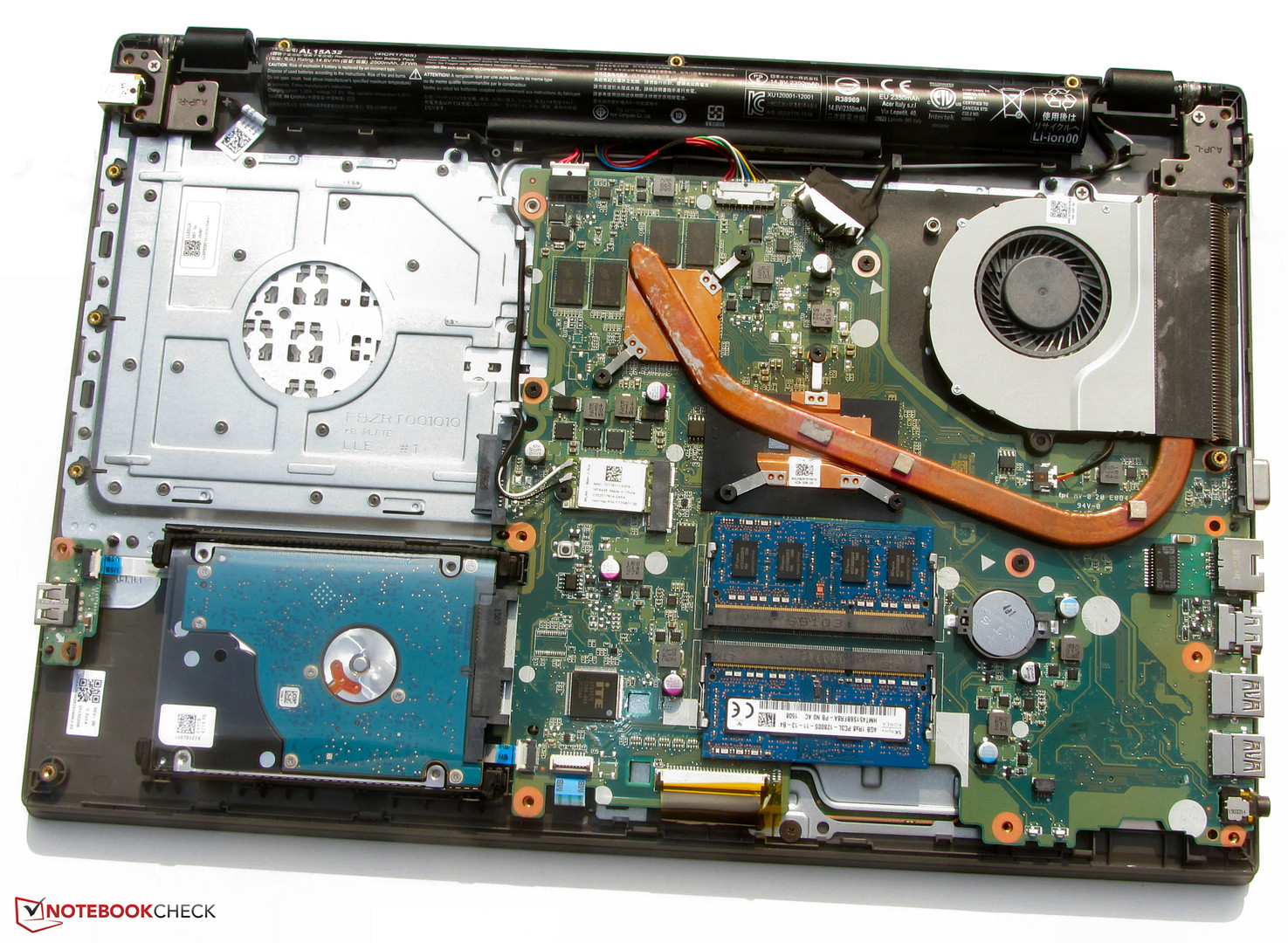

Acer E5-573G

i5 5200u

Nvidia 940M

One heatpipe for both CPU and GPU

Is it safe to make a new thread/grip for a minus screwdriver, with a metal cutting saw?

will it damage the chip?

Acer E5-573G

i5 5200u

Nvidia 940M

One heatpipe for both CPU and GPU