- Joined

- May 27, 2011

- Messages

- 208 (0.04/day)

Sponsored by:

Hello my friends.

About 4 weeks I was doing nothing, My wife was getting crazy.

But now it is here ......... a new build, with a beautiful case, the Silverstone TJ11

When I first saw the case I had something like "I to want to mod this one"

I must admit that a number points are not so nice at this case.

This "negative" points I will certainly adjust. But they have also a lot of beautifull things renewed.

The main hardware and other materials

De hardware:

Case: Silverstone TJ11

PSU: Coolermaster 1200w

Motherboard: I’m not quite sure, but for the fitting and measuring, gonna use a EVGA Classified E759

Processor: i7 930

GPU: 3 x GTX 480

Memory: 6 x 2GB Corsair DDR3 1600

HDD: 2 x SSD 120GB And some sata

Cooling:

Water cooling of course, but have to gather and brainstorm what best suits the TJ

So it’s a bit of a gray area. But I have some great ideas.

For now:

2 x EK 360 radiator

EK HF Supreme plex

EK Ram cooler plex

BitspowerSilver shiny

Tygon tube Transparant

And more…….

Other products/ materials:

MDPC Sleeve, colors: Black and...........yellow

Carbon fiber film

SMD lighting I think, but not too much this time

Some Acryl, yellow and black

About what exactly will happen, I will not say too much for now. I have a lot of ideas

The beginning:

My hero the guy of GLS, delivered the package of highflow.

Luckily, he treats the case with love and the TJ is without damage.

It’s big, really big…………..but beautifull

De Silverstone TJ11

The box

Out of the box

Inside

Top-mounted slide out motherboard tray

9 uninterrupted 5.25” drive bays

9+1 expansion slots

6 x 3.5” hard drive trays

Dual see-through air intake vents

Dual ATX/PS2 PSU compartment

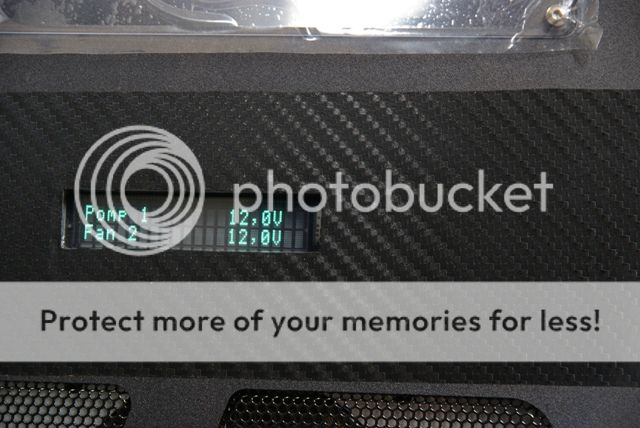

2 x AP121 fans with hot-swap adapters

Extra large motherboard tray cut-out for CPU cooler backplates

And a little box with small stuff

Manual……….lol

Fasteners, unfortunately silver not black. Missed opportunity

SSD Brackets

Horizontal mount bracket for the PSU

Filter

PSU cable

And a Silverstone logo for on the case or something. could laugh about this

Because the painted this on my beautiful expensive case

Do not mind that it’s made in China, but please don’t do this anymore

This was the case step by step. next challenge is to brainstorm how to install the various components.

New case, new challenges I love it

............... to be continued

............... to be continued

Grtzzz.

Last edited:

thanks

thanks