Does it have a timer? I use the timer on my camera when taking pictures on the tripod because of the same thing.

Good point. I'll be doing some more cutting and grinding today. I'll get some better quality pictures of all the gear by friday when my Z77E board, power supply show up. Then we can get the good stuff

Krylon Ultra Flat Black Interior / Exterior Spray paint is a 90% match on color to the factory paint. I just sprayed the cuts with minimal prep to hide mistakes and gouges etc. It looks pretty good up to about an inch away. Also the stuff dries in like 10 minutes and the odor is gone in about 3 hours. Its great. All of that is going to be inside the wood anyway so it doesn't matter. Main difference is factory texture is rough, this is a bit smoother. Wanted to protect the bare metal a bit better and hide some of the dremel bites.

Okay guys, just for the FAN CLUB, I got some better pictures of the fans. This time I used timer mode. Apparently thats the way to get good pictures with a camera that weighs about the same as a feather.

The dual ball bearing on these fans is amazing, soooo smoooth

Here is the radiator install

I am hoping that the ITX board will not hit the end of the radiator. If it does, I will need to move the screw holes forward

Still waiting on the damn board to arrive, its been like 2 weeks. Thanks amazon.

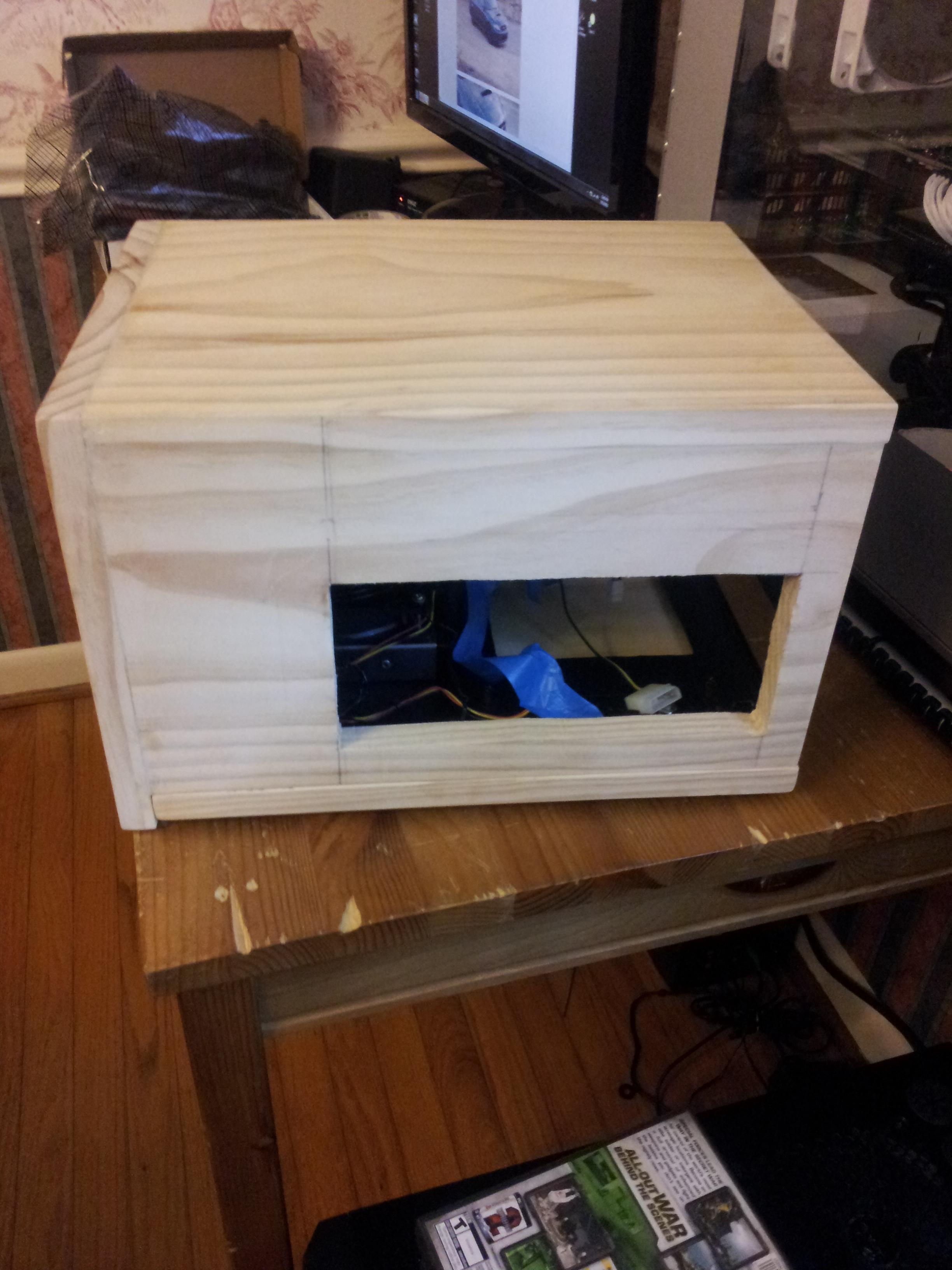

Naked, this box is now all ready for its new, beautiful wood skin. I will start the wood working this weekend assuming the itx board and power supply arrives Friday and the watercooler doesn't start leaking or the thing doesn't explode or something. Bought the Asetek mounting kit from Corsair for $9. Not bad, since I got this AIO loop for FREE! This Asetek is essentially a first generation Corsair H50.

The fan that will exhaust downwards from the radiator will be a Koolance 120mmx25mm dual ball bearing (basically a server fan). I am running all dual ball bearing fans because I want maximum reliability and don't want to open this thing up very much. Its going to be incased in wood and it might not be easy to open. I will probably modify all the fans to run at 7v.

Still waiting on the damn board to arrive, its been like 2 weeks. Thanks amazon.

Still waiting on the damn board to arrive, its been like 2 weeks. Thanks amazon.

You guys are also seeing the clump of turn on wire and case headers that I threw there. The only front panel header to be connected is power and reset. So that whole bundle is going going gone.

You guys are also seeing the clump of turn on wire and case headers that I threw there. The only front panel header to be connected is power and reset. So that whole bundle is going going gone.

.

.