Under such feedback most all thermal pastes would seem to perform nearly the same,

toothpaste included.

That of course is not true. I have never seen any legitimate review that said toothpaste performed "nearly the same" as any legitimate TIM (thermal interface material).

The suggestion to use toothpaste in the first place years ago was done as a silly joke. It never was meant to be taken seriously and it never should be suggested in any way today. The link you included even says toothpaste was not included in their reviews. And for good reasons. Toothpaste is an abrasive. It has bolder size particles (microscopically speaking) in it designed to scrape off tarter and scum. Don't even try it for fun.

Effective working life is another fallacy. Any decent TIM will easily last 5, 10, 15 years or longer AS LONG AS the cured bond between the CPU and heatsink mating surfaces is not broken.

Note there is not one single CPU, GPU, motherboard, computer, heatsink/cooler or even TIM maker, NOT ONE, that says the TIM needs to be replaced every X number of years.

Yes, a fresh new application of TIM "might" yield a couple degrees improved performance. But if you "need" those few degrees to keep from crossing over thermal protection thresholds, then you have other more immediate cooling problems that need addressing first - like case cooling.

Yet another fallacy is the claim that cooler is always better. WRONG! It certainly is absolutely and critically essential to maintain our electronics "comfortably" within its "normal" operating temperature range. No argument there. But there is absolutely nothing that indicates a CPU, as an example, running at 25°C will perform better, be more stable, or have a longer life span than a CPU running at 50 or even 55°C.

So it is absolutely and critically essential to keep our electronics properly cooled, but trying to achieve the coolest temps possible does nothing except, maybe, provide bragging rights.

So it is important to use a quality TIM, but it certainly does not need to be the best rated, or most expensive.

Another fallacy - TIM does NOT need to be replaced if it dries out! The purpose of TIM is to fill the microscopic pits and valleys in the mating surfaces to push out and to prevent insulating air in. The ONLY reason TIM comes in a liquified form is so it can easily be squeezed out of the tube and evenly spread out across the component surface. If the applied TIM dries, the solids within are left behind and still occupying those microscopic pits and valleys and doing their job of keeping insulating air out. This is why "open" tubes of TIM have a shelf life - air has gotten in and hardened the TIM into solid chunks that prevent a smooth application of new TIM.

TIM Rules:

- Use TIM - don't go bare.

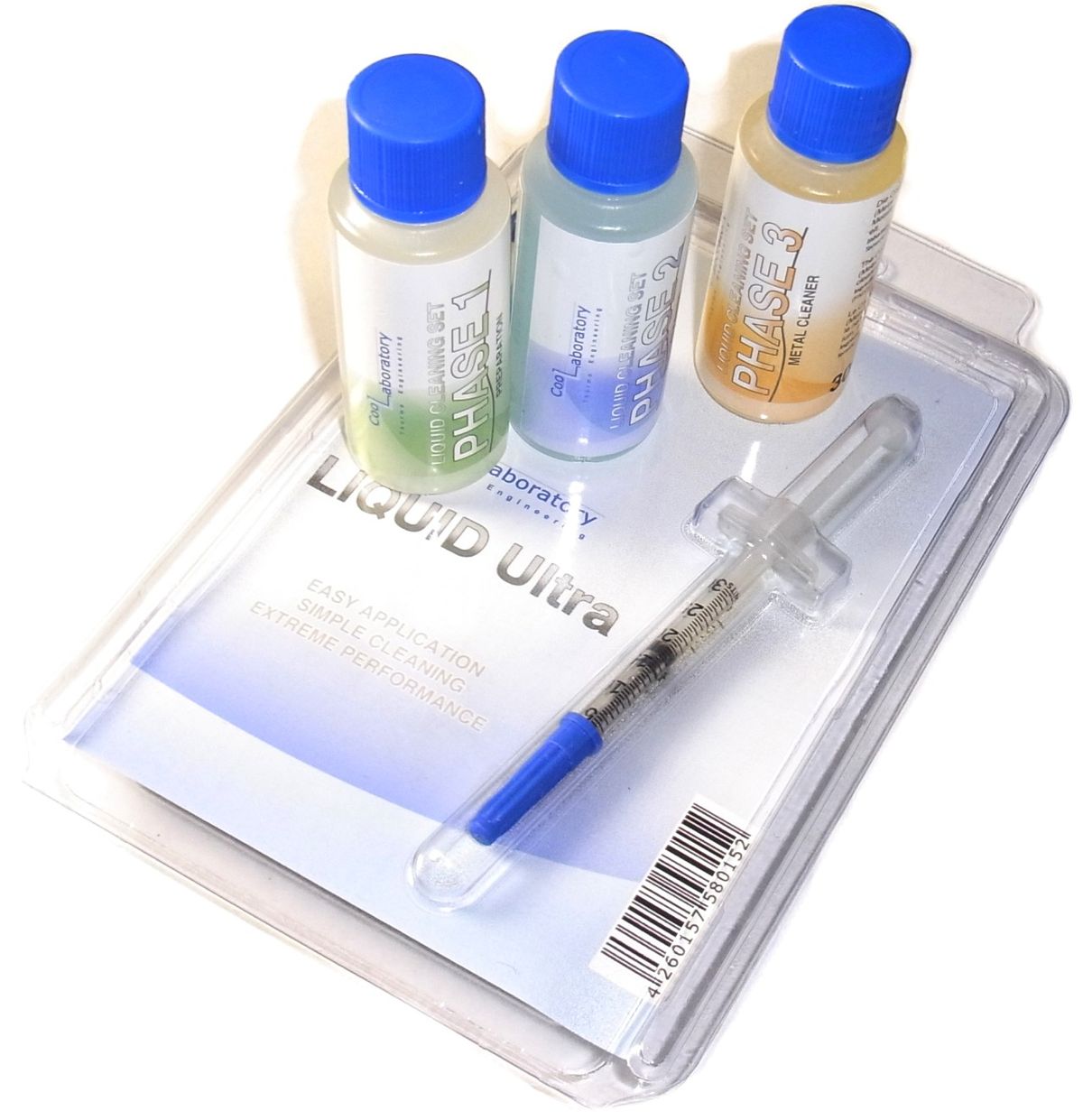

- Thoroughly clean the mating surfaces of old TIM, dust, oils and other grime before applying TIM.

- Too much TIM is "in the way" and "counterproductive" to the most efficient transfer of heat. Apply as thin a layer as possible that still ensures full coverage.

- Mount the heatsink assembly properly.

- Once mounted, do not twist the heatsink to see if it is loose - you are likely to break the cured bond, making it loose which then allows insulating air in between the mating surfaces. In other words, once properly applied and the cooler mounted, LEAVE IT ALONE!