- Joined

- Dec 16, 2010

- Messages

- 1,686 (0.32/day)

- Location

- State College, PA, US

| System Name | My Surround PC |

|---|---|

| Processor | AMD Ryzen 9 7950X3D |

| Motherboard | ASUS STRIX X670E-F |

| Cooling | Swiftech MCP35X / EK Quantum CPU / Alphacool GPU / XSPC 480mm w/ Corsair Fans |

| Memory | 96GB (2 x 48 GB) G.Skill DDR5-6000 CL30 |

| Video Card(s) | MSI NVIDIA GeForce RTX 4090 Suprim X 24GB |

| Storage | WD SN850 2TB, Samsung PM981a 1TB, 4 x 4TB + 1 x 10TB HGST NAS HDD for Windows Storage Spaces |

| Display(s) | 2 x Viotek GFI27QXA 27" 4K 120Hz + LG UH850 4K 60Hz + HMD |

| Case | NZXT Source 530 |

| Audio Device(s) | Sony MDR-7506 / Logitech Z-5500 5.1 |

| Power Supply | Corsair RM1000x 1 kW |

| Mouse | Patriot Viper V560 |

| Keyboard | Corsair K100 |

| VR HMD | HP Reverb G2 |

| Software | Windows 11 Pro x64 |

| Benchmark Scores | Mellanox ConnectX-3 10 Gb/s Fiber Network Card |

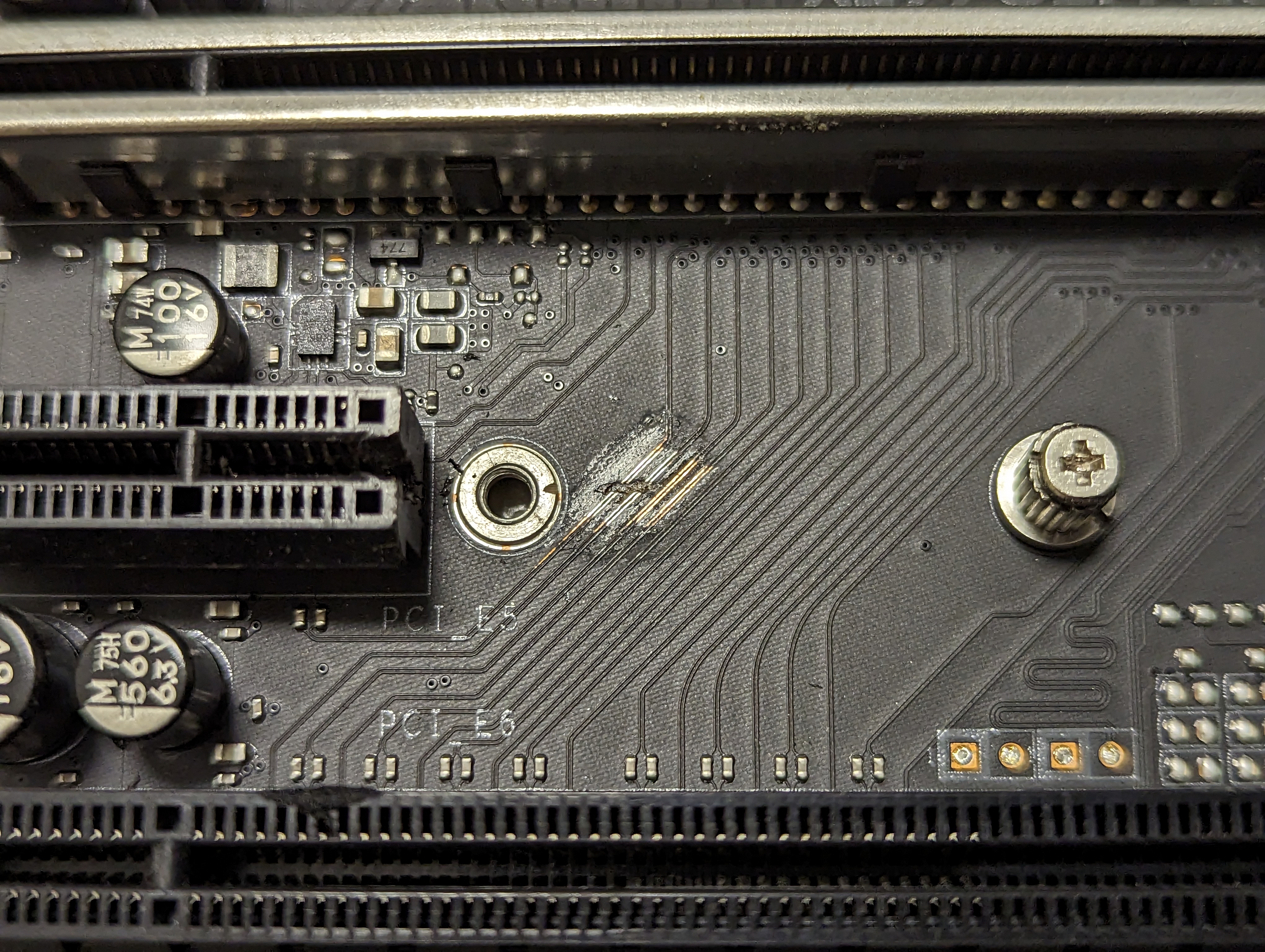

I made a dumb mistake tonight. Have an MSI X299 SLI Plus motherboard. I needed to cut the end of a PCIe x1 so I could put a PCIe x4 card in it. I was using a file, and I slipped and damaged some traces on the PCB. They connect to lanes 1 and 2 of the lowermost x16 slot. If I didn't need the slot, I would just leave it as-is since there is nothing else damaged, but I do need to use that slot and need to repair it.

What would be the best way to repair those traces? I tried making a solder connection but those traces are way smaller than even the tiniest tip I have and the solder just balls up instead of bridging the traces. I was thinking that painting conductive paint on the board might be the best solution since I can scrape off the paint where I don't need it. Is there another method I'm not thinking about?

What would be the best way to repair those traces? I tried making a solder connection but those traces are way smaller than even the tiniest tip I have and the solder just balls up instead of bridging the traces. I was thinking that painting conductive paint on the board might be the best solution since I can scrape off the paint where I don't need it. Is there another method I'm not thinking about?