- Joined

- Feb 20, 2020

- Messages

- 9,340 (4.72/day)

- Location

- Louisiana

| System Name | Ghetto Rigs z490|x99|Acer 17 Nitro 7840hs/ 5600c40-2x16/ 4060/ 1tb acer stock m.2/ 4tb sn850x |

|---|---|

| Processor | 10900k w/Optimus Foundation | 5930k w/Black Noctua D15 |

| Motherboard | z490 Maximus XII Apex | x99 Sabertooth |

| Cooling | oCool D5 res-combo/280 GTX/ Optimus Foundation/ gpu water block | Blk D15 |

| Memory | Trident-Z Royal 4000c16 2x16gb | Trident-Z 3200c14 4x8gb |

| Video Card(s) | Titan Xp-water | evga 980ti gaming-w/ air |

| Storage | 970evo+500gb & sn850x 4tb | 860 pro 256gb | Acer m.2 1tb/ sn850x 4tb| Many2.5" sata's ssd 3.5hdd's |

| Display(s) | 1-AOC G2460PG 24"G-Sync 144Hz/ 2nd 1-ASUS VG248QE 24"/ 3rd LG 43" series |

| Case | D450 | Cherry Entertainment center on Test bench |

| Audio Device(s) | Built in Realtek x2 with 2-Insignia 2.0 sound bars & 1-LG sound bar |

| Power Supply | EVGA 1000P2 with APC AX1500 | 850P2 with CyberPower-GX1325U |

| Mouse | Redragon 901 Perdition x3 |

| Keyboard | G710+x3 |

| Software | Win-7 pro x3 and win-10 & 11pro x3 |

| Benchmark Scores | Are in the benchmark section |

Hi,

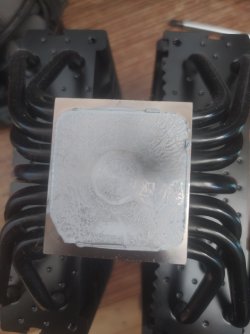

AMD thermal ink

AMD thermal ink