OneMoar

There is Always Moar

- Joined

- Apr 9, 2010

- Messages

- 8,859 (1.59/day)

- Location

- Rochester area

| System Name | RPC MK2.5 |

|---|---|

| Processor | Ryzen 5800x |

| Motherboard | Gigabyte Aorus Pro V2 |

| Cooling | Thermalright Phantom Spirit SE |

| Memory | CL16 BL2K16G36C16U4RL 3600 1:1 micron e-die |

| Video Card(s) | GIGABYTE RTX 3070 Ti GAMING OC |

| Storage | Nextorage NE1N 2TB ADATA SX8200PRO NVME 512GB, Intel 545s 500GBSSD, ADATA SU800 SSD, 3TB Spinner |

| Display(s) | LG Ultra Gear 32 1440p 165hz Dell 1440p 75hz |

| Case | Phanteks P300 /w 300A front panel conversion |

| Audio Device(s) | onboard |

| Power Supply | SeaSonic Focus+ Platinum 750W |

| Mouse | Kone burst Pro |

| Keyboard | SteelSeries Apex 7 |

| Software | Windows 11 +startisallback |

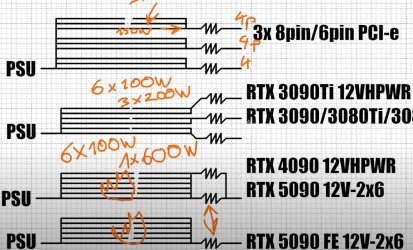

sir ill have you know that logic and understand standing of basic electrical theory are not discussed here and I thank you to go back to corporate pizzle sucking like the rest of these fine people /sCorrosion to plated pins after fretting was one example of how pins can go bad as a result of insertions, which you said cannot happen. So yes, it is a valid example and no, I did not claim that pins should be plated or non-plated.

Also, yes, this is a good point (the bolded part). These are cheaply made cables unfit for purpose. This is the whole discussion point that you seem to be missing by making a really bad assumption. Your argument above the bolded part suggests that because you have a good connector, all pin/socket connectors are good. This is ridiculous. As I've suggested previously in this thread (no idea how many pages ago at this point), the connector we're talking about would be totally fine if it was used for a lower powered application where there's more margin. The current usage is too close to the rated specification and there aren't good enough safeguards. They are cheaply made in bulk and too prone to issues. That's it. That's the whole situation.

seriously folks a first year engineer would understand why this entire design from card to cable is just a bad idea .... its been a bad idea since it was cooked up in a meth and lsd fugue state by some undergrad surfing mouser after some schmuck upper management person directed them to design something different