- Joined

- Jun 5, 2025

- Messages

- 33 (0.66/day)

$=Dollar

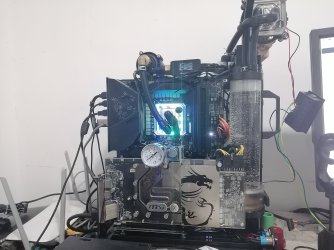

CPU:intel 10600Kes 5g 1.23v 55$(Secondhand)

GPU:msi 1070ti 97$(Secondhand)

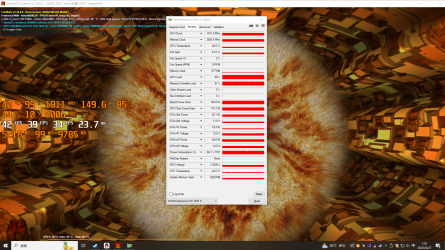

mainboard:msi z490 unify 48$(Secondhand)

memory:asgard Samsung B-die 8G*2 OC4400C16 66$(brand new)

1、CPU cold head model:bykski 0.08mm,9.49$(brand new)

2、Graphics card cold head model:MSI GTX 1080 SEA HAWK EK X,6.98$(Secondhand)

This card has no light slot, so I can't install the light strip, which is a bit frustrating for me

3、Water pumps and tanks:bykski Lift height 5 meters, Flow rate 1000L/H,32$(Secondhand)

4、Pump in the upper left corner:ZKSJ 24VDC55E ,Head 16 meters,Flow rate 2400L/H,36$(brand new).

Not on yet, I added this pump to test the temperature difference at high and low flows. At the same time, I have tested that this pump can reach 14L/min without a heat source and only connected to the copper radiator cycle. However, when I tested the flow rate of 7L/min, the noise was unbearable, which was a big drawback.

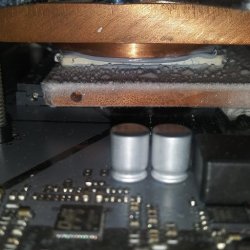

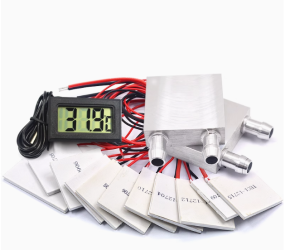

5、Semiconductor chilled sheets:TEC1-12703,12V 30W,1.81$(brand new)。

It is installed behind the CPU cooler in the upper right corner, and it wants to further cool the cooling circuit by measuring the cooling sheet. Unfortunately, it's hard to cool down when the computer is on standby. It may require 10 times the cooling capacity of the semiconductor cooling chip to be effective. But the cost of power consumption and electricity is too high, and I don't want to try again.

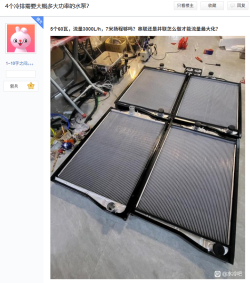

6、Copper radiator:bykski,240+360,55.8$(brand new).

I would like to say that this copper radiator has a great disadvantage, it has a large amount of flux required for soldering during manufacturing, and it is difficult for our users to clean it after they buy it. When the cleaning is not thorough, as long as 1 to 2 weeks, the inner wall of the transparent water pipe of the waterway will adhere to the white powder, and the bottom of the water tank will also precipitate white powder, this problem has bothered me for a long time, I am very distressed, I don't know if there will be improvement after this cleaning

7、Temperature sharing: When I was playing the PUBG game, the room temperature was 24°C, the water temperature was °C, the CPU was 40°C-45°C, the GPU was 36°C, the flow rate was 2.4L/min, and the pressure was 0.3bar

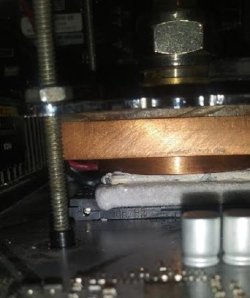

8、Finally, I wanted to open the lid and remove the cover from the CPU (which I had already done), and use the cold head to make direct contact with the liquid metal, but unfortunately I couldn't find the right fastener, so I even polished the four plastic corners of the CPU base of the motherboard to put the buckle in order to fit it properly. The graphics card also wants to conduct heat and also wants to use liquid metal, but I don't know how to prevent it from leaking. Also, I want to use Coollaboratory Liquid Extreme, but it is not available in China. In this regard, can you give me some suggestions or comments, welcome to leave an interactive message for exchange

Please comment on my water cooling, I hope you can give me some suggestions for further lowering the temperature, such as material, choice, brand. It's too expensive for me to afford, you don't need to recommend it, haha, just the parts of the ordinary civilian consumption level.

CPU:intel 10600Kes 5g 1.23v 55$(Secondhand)

GPU:msi 1070ti 97$(Secondhand)

mainboard:msi z490 unify 48$(Secondhand)

memory:asgard Samsung B-die 8G*2 OC4400C16 66$(brand new)

1、CPU cold head model:bykski 0.08mm,9.49$(brand new)

2、Graphics card cold head model:MSI GTX 1080 SEA HAWK EK X,6.98$(Secondhand)

This card has no light slot, so I can't install the light strip, which is a bit frustrating for me

3、Water pumps and tanks:bykski Lift height 5 meters, Flow rate 1000L/H,32$(Secondhand)

4、Pump in the upper left corner:ZKSJ 24VDC55E ,Head 16 meters,Flow rate 2400L/H,36$(brand new).

Not on yet, I added this pump to test the temperature difference at high and low flows. At the same time, I have tested that this pump can reach 14L/min without a heat source and only connected to the copper radiator cycle. However, when I tested the flow rate of 7L/min, the noise was unbearable, which was a big drawback.

5、Semiconductor chilled sheets:TEC1-12703,12V 30W,1.81$(brand new)。

It is installed behind the CPU cooler in the upper right corner, and it wants to further cool the cooling circuit by measuring the cooling sheet. Unfortunately, it's hard to cool down when the computer is on standby. It may require 10 times the cooling capacity of the semiconductor cooling chip to be effective. But the cost of power consumption and electricity is too high, and I don't want to try again.

6、Copper radiator:bykski,240+360,55.8$(brand new).

I would like to say that this copper radiator has a great disadvantage, it has a large amount of flux required for soldering during manufacturing, and it is difficult for our users to clean it after they buy it. When the cleaning is not thorough, as long as 1 to 2 weeks, the inner wall of the transparent water pipe of the waterway will adhere to the white powder, and the bottom of the water tank will also precipitate white powder, this problem has bothered me for a long time, I am very distressed, I don't know if there will be improvement after this cleaning

7、Temperature sharing: When I was playing the PUBG game, the room temperature was 24°C, the water temperature was °C, the CPU was 40°C-45°C, the GPU was 36°C, the flow rate was 2.4L/min, and the pressure was 0.3bar

8、Finally, I wanted to open the lid and remove the cover from the CPU (which I had already done), and use the cold head to make direct contact with the liquid metal, but unfortunately I couldn't find the right fastener, so I even polished the four plastic corners of the CPU base of the motherboard to put the buckle in order to fit it properly. The graphics card also wants to conduct heat and also wants to use liquid metal, but I don't know how to prevent it from leaking. Also, I want to use Coollaboratory Liquid Extreme, but it is not available in China. In this regard, can you give me some suggestions or comments, welcome to leave an interactive message for exchange

Please comment on my water cooling, I hope you can give me some suggestions for further lowering the temperature, such as material, choice, brand. It's too expensive for me to afford, you don't need to recommend it, haha, just the parts of the ordinary civilian consumption level.

Attachments

-

8A31BDFC30163F1D03BE7CCF36556957.jpg1.2 MB · Views: 118

8A31BDFC30163F1D03BE7CCF36556957.jpg1.2 MB · Views: 118 -

719DE6754E861BCC937E1F7512D668FA.jpg1.5 MB · Views: 122

719DE6754E861BCC937E1F7512D668FA.jpg1.5 MB · Views: 122 -

GD3EK水冷卡室温28.5水温33.2.png2.8 MB · Views: 107

GD3EK水冷卡室温28.5水温33.2.png2.8 MB · Views: 107 -

QQ20250627-191339.png850.1 KB · Views: 91

QQ20250627-191339.png850.1 KB · Views: 91 -

This is the semiconductor refrigeration sheet I mentioned in the fifth article.png323.4 KB · Views: 103

This is the semiconductor refrigeration sheet I mentioned in the fifth article.png323.4 KB · Views: 103