- Joined

- Aug 4, 2014

- Messages

- 115 (0.03/day)

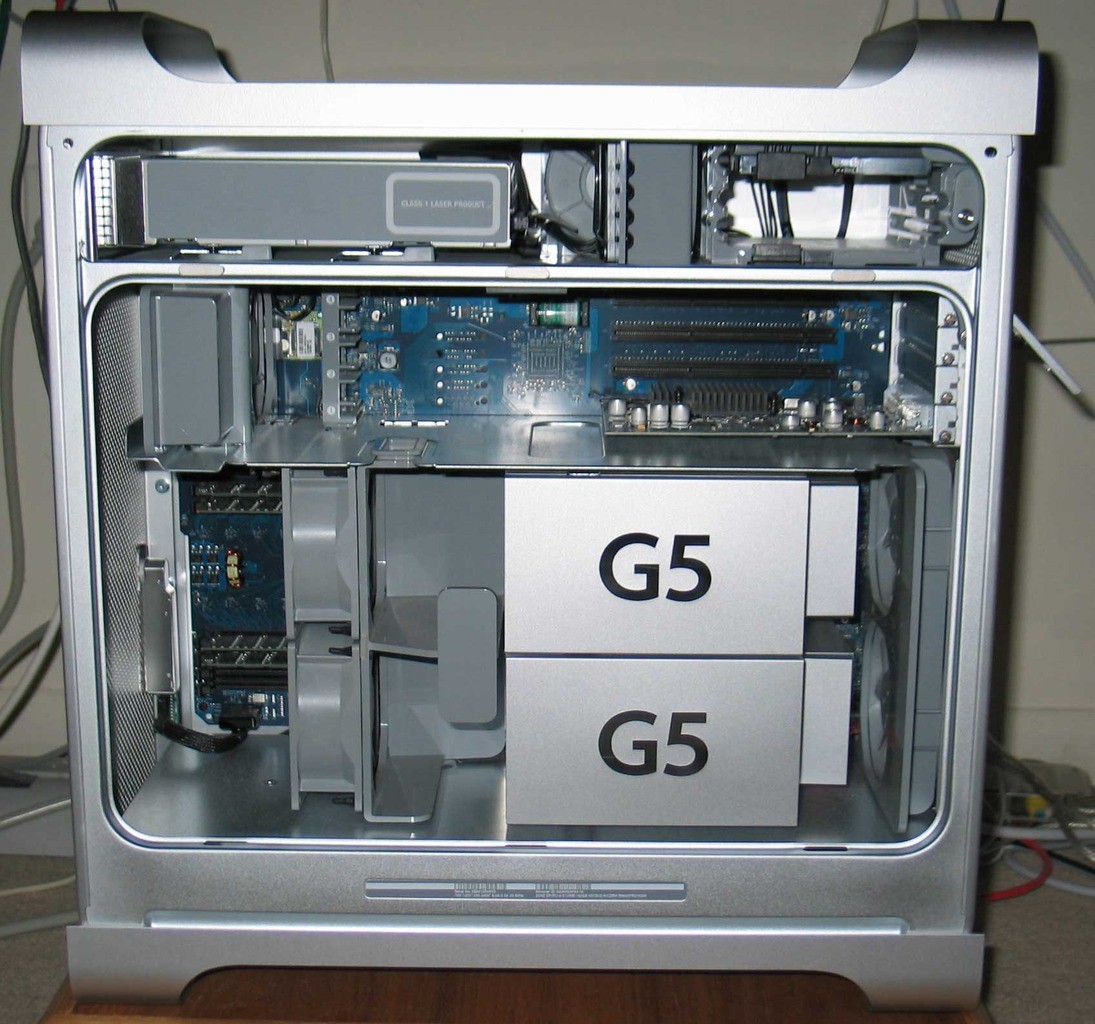

This time my case to mod is a classic. Powermac G5. One of the most popular and ,one of the most modded beauttiful case ever made. As robustness , ı can say it is a PANZER.

someone showed his love like ...

Some prefer to use such

Powermac G5 is one oft most modded case. but most of them, changed outlook of the case

My goals for this Project were to preserve the look of the case at outside ;and fit my PC s hardware including a full ATX MB. And watercooling.

I will to mod at two stages

First the mod on the case and and convert it for an ATX (BTX) MB …

Thenn as second mod to this case... for Watercooling… with acrylic tubing and alphacool capecora passive rads 642+142= 742

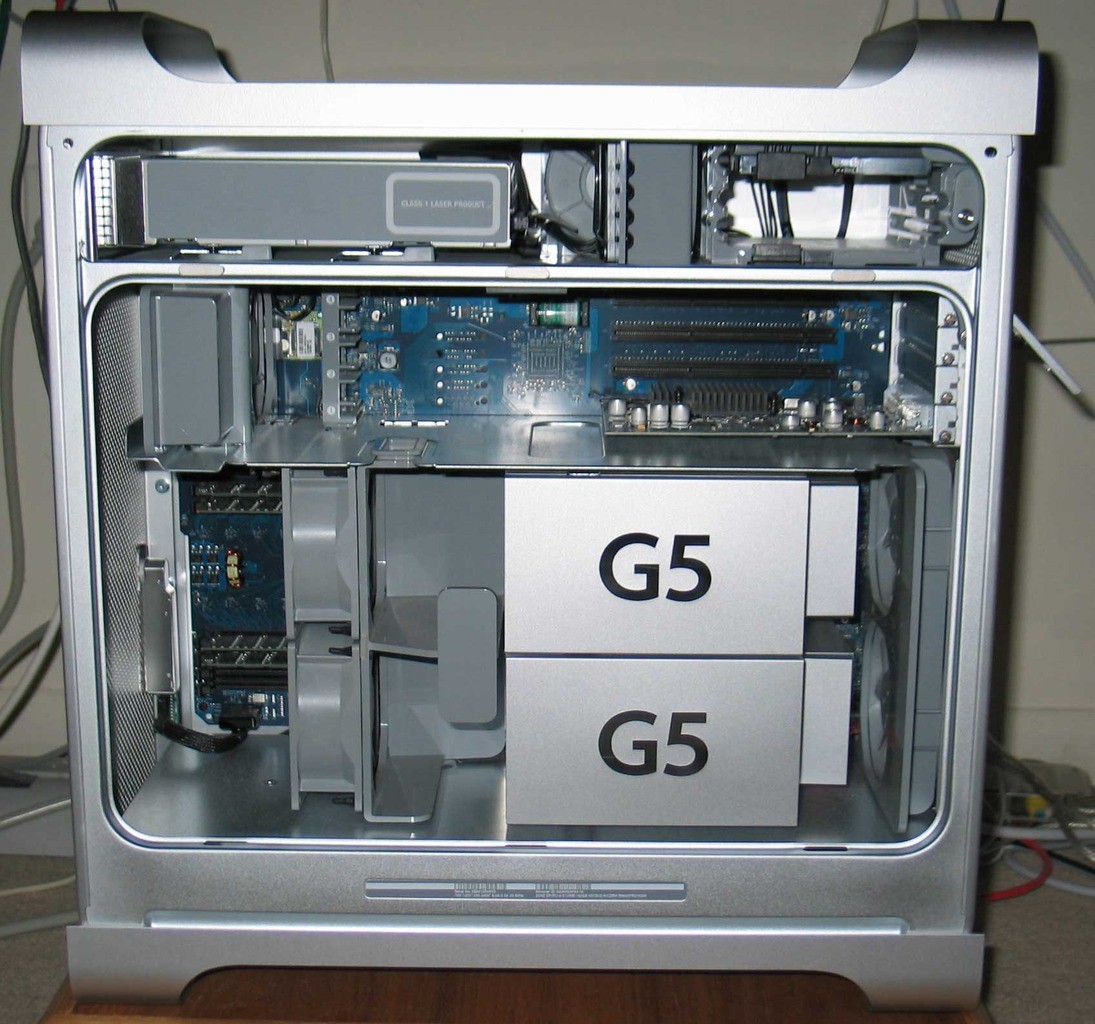

To use an ATX mainboard at this case, the back panel must be changed.

İf we wannt to adapt the case to new motherboard. We must change

At the back panel, the fans must be moved off center, to make a new I/O. and a larger room

for 7 slots

There are a lot of mods, one of them is ,

to make a half mask as Ben Katz did.

Link: http://build-its.blogspot.com.tr/2011/04/how-to-fit-your-pc-in-power-mac-g5-case.html

and mount them to thecase

Or we can use a MB tray with backpanel as gibsonc did.

Link : http://www.insanelymac.com/forum/topic/281165-powermac-g5-case-mod/

And cut the case, to make a space

And mount it

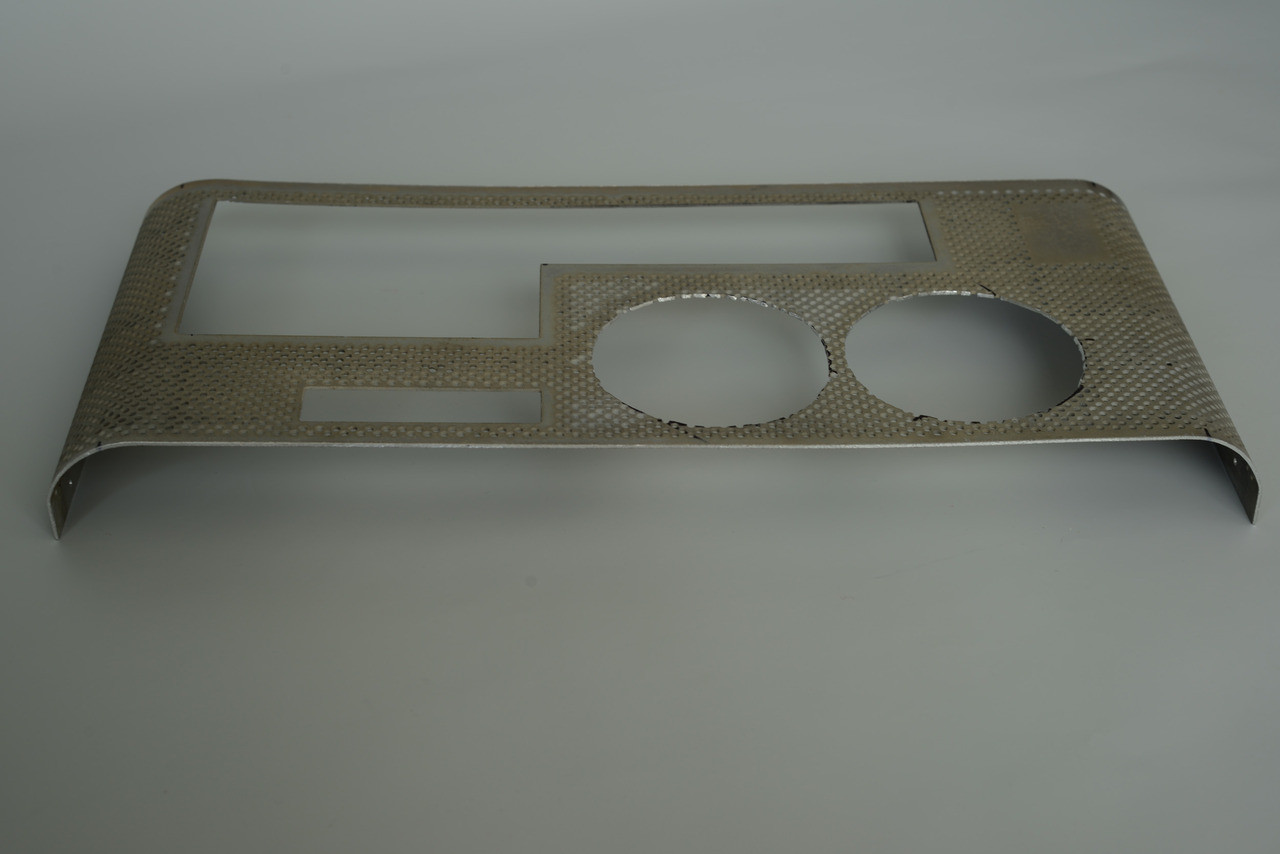

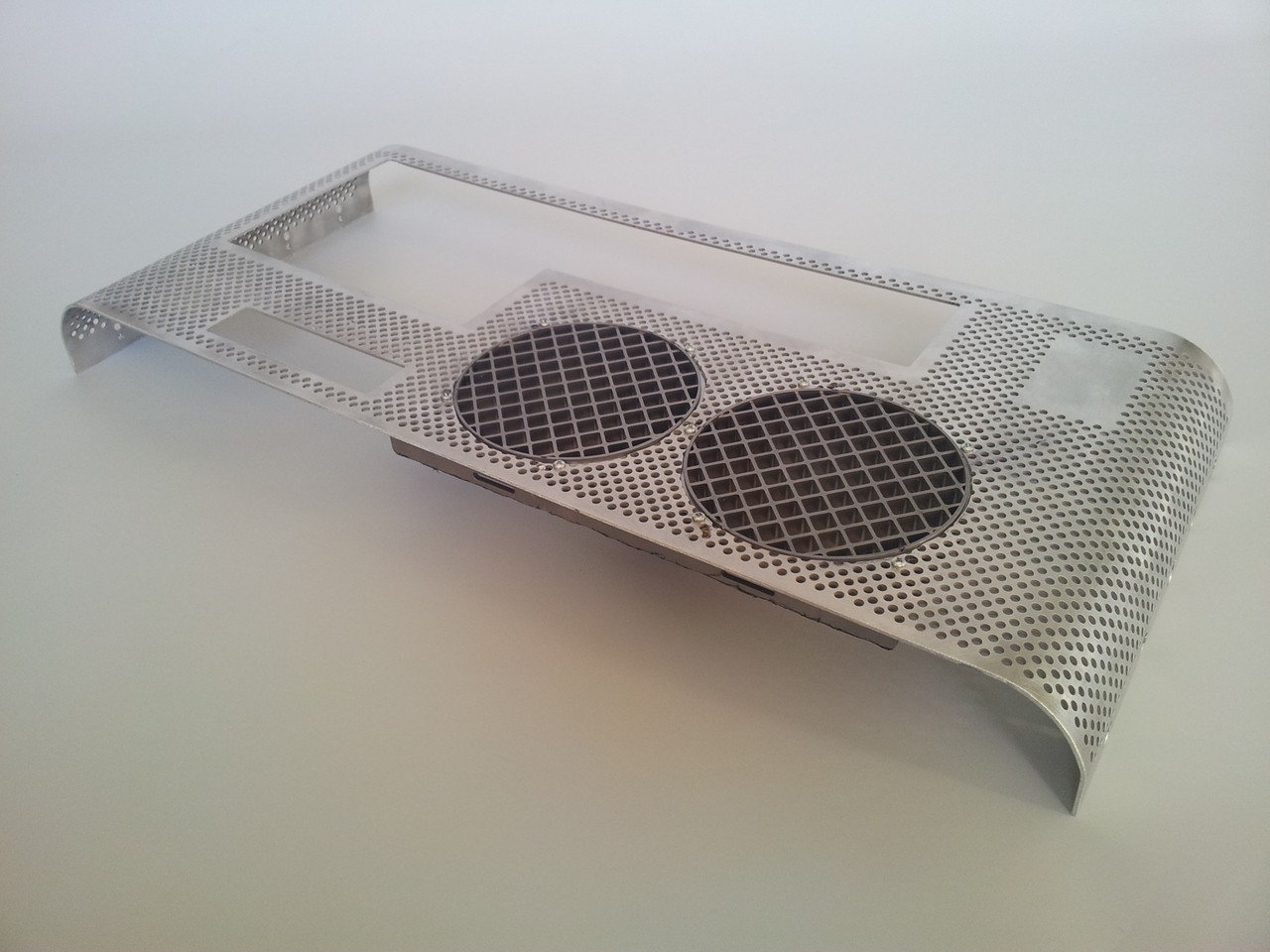

But I wannt to make a new back panel complett. With new fan holes , I/O and slots.

I wannt to use the original fangrill as well.

Drawn at corel... but ı musst make nearly 3000 circles with 3mm Radius..

And sent to water jet for cutting….

OTHER WORKLOGS

PLAYDOH SILVERSTONE TJ07 (Acrylic pipe and midplate)

http://www.techpowerup.com/forums/threads/playdoh-silverstone-tj07-acrylic-tubing.206894/

TRANSFORMER CASE COMPLETED

http://www.techpowerup.com/forums/threads/transformer.204111/

Jumbo case- custom build- COMPLETED

http://www.techpowerup.com/forums/threads/jumbo-case-custom-build.205943/

4 way HDD switcher. COMPLETED

http://www.techpowerup.com/forums/threads/4-way-hdd-switcher.203795/

Grapich Equaliser display COMPLETED

http://www.techpowerup.com/forums/threads/graphic-equaliser-display.203871/

900 D MMT CASE COMPLETED

http://www.techpowerup.com/forums/threads/900-d-mmt-case.204028/

12 Angry Men 900 D Case COMPLETED

http://www.techpowerup.com/forums/threads/12-angry-men-900-d-case.203915/

someone showed his love like ...

Some prefer to use such

Powermac G5 is one oft most modded case. but most of them, changed outlook of the case

My goals for this Project were to preserve the look of the case at outside ;and fit my PC s hardware including a full ATX MB. And watercooling.

I will to mod at two stages

First the mod on the case and and convert it for an ATX (BTX) MB …

Thenn as second mod to this case... for Watercooling… with acrylic tubing and alphacool capecora passive rads 642+142= 742

To use an ATX mainboard at this case, the back panel must be changed.

İf we wannt to adapt the case to new motherboard. We must change

At the back panel, the fans must be moved off center, to make a new I/O. and a larger room

for 7 slots

There are a lot of mods, one of them is ,

to make a half mask as Ben Katz did.

Link: http://build-its.blogspot.com.tr/2011/04/how-to-fit-your-pc-in-power-mac-g5-case.html

and mount them to thecase

Or we can use a MB tray with backpanel as gibsonc did.

Link : http://www.insanelymac.com/forum/topic/281165-powermac-g5-case-mod/

And cut the case, to make a space

And mount it

But I wannt to make a new back panel complett. With new fan holes , I/O and slots.

I wannt to use the original fangrill as well.

Drawn at corel... but ı musst make nearly 3000 circles with 3mm Radius..

And sent to water jet for cutting….

OTHER WORKLOGS

PLAYDOH SILVERSTONE TJ07 (Acrylic pipe and midplate)

http://www.techpowerup.com/forums/threads/playdoh-silverstone-tj07-acrylic-tubing.206894/

TRANSFORMER CASE COMPLETED

http://www.techpowerup.com/forums/threads/transformer.204111/

Jumbo case- custom build- COMPLETED

http://www.techpowerup.com/forums/threads/jumbo-case-custom-build.205943/

4 way HDD switcher. COMPLETED

http://www.techpowerup.com/forums/threads/4-way-hdd-switcher.203795/

Grapich Equaliser display COMPLETED

http://www.techpowerup.com/forums/threads/graphic-equaliser-display.203871/

900 D MMT CASE COMPLETED

http://www.techpowerup.com/forums/threads/900-d-mmt-case.204028/

12 Angry Men 900 D Case COMPLETED

http://www.techpowerup.com/forums/threads/12-angry-men-900-d-case.203915/

Last edited:

![URL]]](/forums/proxy.php?image=http%3A%2F%2F%5BURL%3D%27http%3A%2F%2Fimagizer.imageshack.us%2Fv2%2F1280x1024q90%2F537%2FQxuCEm.jpg%255b%2FIMG%27%5Dhttp%3A%2F%2Fimagizer.imageshack.us%2Fv2%2F1280x1024q90%2F537%2FQxuCEm.jpg%5B%2FIMG%5B%2FURL%5D%5D&hash=754db31d77576f4116830377b74b6cc1)

nice work man )

nice work man )