- Joined

- Jun 7, 2015

- Messages

- 38 (0.01/day)

- Location

- France

| System Name | HAL (modded, 1.3U "pizza box") |

|---|---|

| Processor | Intel Core i7 4790K @4.6GHz |

| Motherboard | Asus ROG Maximus Impact VI |

| Cooling | Custom (flexible) loop: Alphacool NexXxoS XP³ Light / EK SBAY DDC 3.2 PWM / 2x Magicool G2 240 rads |

| Memory | 2x8Go DDR3 2400 - G-Skill Trident X |

| Video Card(s) | EVGA Geforce GTX 1080 Hydro Copper |

| Storage | Crucial M500 M.2 480GB + Samsung QVO 860 1TB SATA |

| Display(s) | HP Omen 35" 3440x1440 GSync 100Hz |

| Case | Modded iSTAR USA D-107V2, 1,3U rack case |

| Audio Device(s) | none |

| Power Supply | Corsair SF600 (SFX) |

| Mouse | Corsair Vengeance M65 |

| Keyboard | Cooler Master Quick Fire pro |

| Benchmark Scores | 3D Mark Time Spy: 7361 ( https://www.3dmark.com/spy/5334187 ) |

Hi everyone!

I just started working on the follow-up of my HAL (modded 1.3U server case) project.

This time it will be built from scratch.

Constraints:

- Shorter depth and a bit more eight to free some space on my desk

- Still under the monitor (HP Omen 35), while finding a way to highlight its great looking octogonal stand.

- Still a custom loop for CPU and GPU, but improving airflow for non-watercooled components.

- cheap material, easy to work with... and delivered at home.

Here was my first rough idea but it's evolving as I bump into unforeseen constrains and new (and hopefully good) ideas:

HAL 2.0 first concept

The idea:

- Octogonal shape, to repeat the shape of the monitor stand.

- For the material, I opted for wood, with 0.5 inch square dowels as the main material for the case... top and bottom plates will be meshs of intertwinned dowel which will require quite some work with grooves.

- Smaller parts will be 3D printed in PLA.

- The finish will be deep mate black with red accents (mostly from leds), to fit the HAL theme.

Tools:

- Just invested in a BIQU B1 3D printer (basically an upgraded Ender 3)...

- ... and I also got a Sainsmart Genmitsu 3018 ProVer CNC machine.

- I am taking this new project as an opportunity to learn the basics of Autodesk Fusion 360, especially for 3D printed parts (slicing with Cura). To work on grooves I am using Inventable Easel to generate the g-code for the CNC machine.

- Electric mitter saw.

- Dremel

Nothing really fancy in terms of PC parts... my good old OCed Core i7 4790k, Asus ROG Maximus Impact VI (such a wonderful card) and EVGA Geforce GTX 1080 Hydrocopper. Only slight upgrade is a full cover waterblock from Bitspower for the motherboard.

Here is a first attempt at assessing the internal layout and dimensions (the cardboard way... it was a few weeks ago and I could barely design anything on Fusion 360).

Low-tech design

By the look of it my 2x 240 slim rads won't really fit inside... I am going to install them outside (using pass-throughs), in the back of the case, raised vertically.

Due to the octogonal shape and overall clearance, I will have a rather unusual layout for the mother board and (single-slot) GPU: "crossed", GPU underneath the motherboard, with motherboard connectors on the rear left and gpu connections on the rear right.

First scratchbuild (in ages, I had a few rather aesthetically unfortunate attempts at cubic acrylic cases back in the 90s), first 3D printer, first CNC, first steps in CAD... this is going to be hectic and fun.

I will documents my steps (and missteps) so that it may be useful to some of you wishing to embark in similar projects

Next step: lots of dowels cutting, sanding and assembling.

FIRST UPDATE

I. Working on the bottom plate.

I decided to work on the bottom plate first, as a way to identify potential issue and improve things before I work on the top plate which will obvious be much more visible.

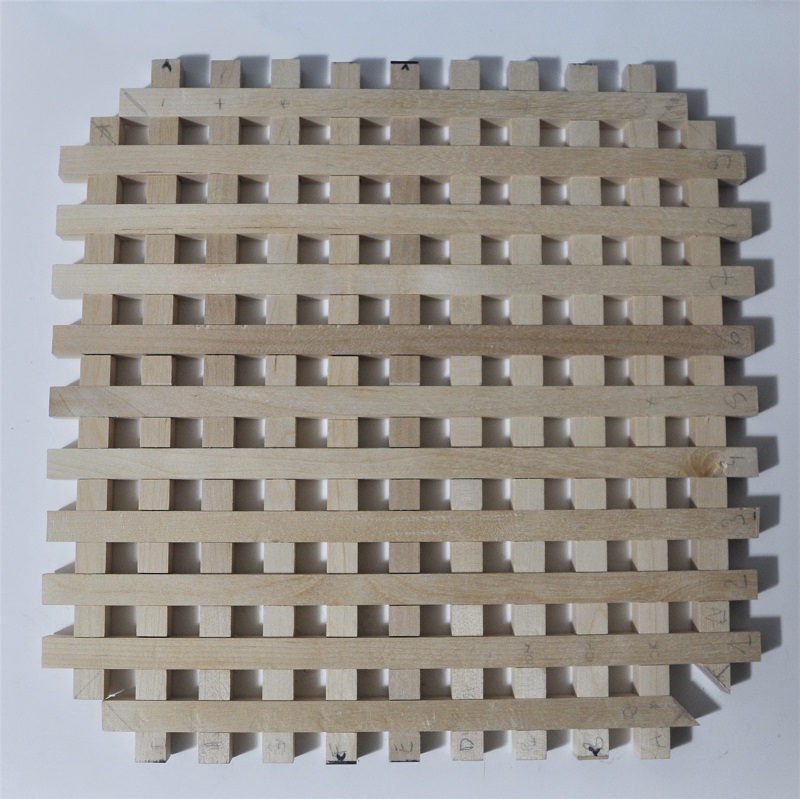

The idea is to intertwine square dowels which will create more rigidity than just carving square holes in a sheet of wood (especially for the top plate which will support the monitor.

Cutting

The bottom plate is assembled from a set of 11.5" and 9.5" dowels.

Here is a first rough layout before grooves are carved.

I used Inventable Easel (free version) to design the grooves and generate the Gcode.

CNC baby!!! (carving grooves in 11.5" dowels, 9 at a time)

This was my first cut just after the models presented by Sainsmart.

- I used A Dremel 654 1/4" Straight Routing Bit: with it's 1/8" shank it works well with the collet included with the 3018 by default, but make the job much faster than with a 1/8" bit, it seems to work will on these poplar dowels.

- Dowels are fixed to the spoilboard with the painter tape + superglue trick.

- compared to usual wood CNC works I don't cut full pieces from a plain wood stock... this requires quite some precision in the alignment of the origin, which proved to be tricky...

- also considering that the carving area is actually a bit less wide than 30cm due to limit stoppers... I had to have a second pass for the last groove... with risks of alignment inconsistencies. Thinking twice a larger CNC would have been a better choice but there is quite a price bump past the 3018, as they come with more than just a bigger frame (more powerful motors etc...). I will at least probably buy the 3040 extension kit for 3018 from Sainsmart or make my own soon.

- appart from alignment consistency, one thing i did not think about at all was tolerance, especially for grooves... Down the line, this required quite a lot of filing and sanding to adjust everything.

- this was all the more real as these dowels come with slight discrepencies in thickness are sometimes not perfectly straight. Grain is very random too.

The bottom plate after grooves are cut, and rough sanding/filing.

I will attach the side dowels later on as the basically lock everything in place, then apply a bit of wood filler on some spots and sand more.

The objective throughout this build is to avoid the wooden look and feel, so sanding is going to be long.

Next step: working on wooden side pannels, mostly a mitter saw job.

I just started working on the follow-up of my HAL (modded 1.3U server case) project.

This time it will be built from scratch.

Constraints:

- Shorter depth and a bit more eight to free some space on my desk

- Still under the monitor (HP Omen 35), while finding a way to highlight its great looking octogonal stand.

- Still a custom loop for CPU and GPU, but improving airflow for non-watercooled components.

- cheap material, easy to work with... and delivered at home.

Here was my first rough idea but it's evolving as I bump into unforeseen constrains and new (and hopefully good) ideas:

HAL 2.0 first concept

The idea:

- Octogonal shape, to repeat the shape of the monitor stand.

- For the material, I opted for wood, with 0.5 inch square dowels as the main material for the case... top and bottom plates will be meshs of intertwinned dowel which will require quite some work with grooves.

- Smaller parts will be 3D printed in PLA.

- The finish will be deep mate black with red accents (mostly from leds), to fit the HAL theme.

Tools:

- Just invested in a BIQU B1 3D printer (basically an upgraded Ender 3)...

- ... and I also got a Sainsmart Genmitsu 3018 ProVer CNC machine.

- I am taking this new project as an opportunity to learn the basics of Autodesk Fusion 360, especially for 3D printed parts (slicing with Cura). To work on grooves I am using Inventable Easel to generate the g-code for the CNC machine.

- Electric mitter saw.

- Dremel

Nothing really fancy in terms of PC parts... my good old OCed Core i7 4790k, Asus ROG Maximus Impact VI (such a wonderful card) and EVGA Geforce GTX 1080 Hydrocopper. Only slight upgrade is a full cover waterblock from Bitspower for the motherboard.

Here is a first attempt at assessing the internal layout and dimensions (the cardboard way... it was a few weeks ago and I could barely design anything on Fusion 360).

Low-tech design

By the look of it my 2x 240 slim rads won't really fit inside... I am going to install them outside (using pass-throughs), in the back of the case, raised vertically.

Due to the octogonal shape and overall clearance, I will have a rather unusual layout for the mother board and (single-slot) GPU: "crossed", GPU underneath the motherboard, with motherboard connectors on the rear left and gpu connections on the rear right.

First scratchbuild (in ages, I had a few rather aesthetically unfortunate attempts at cubic acrylic cases back in the 90s), first 3D printer, first CNC, first steps in CAD... this is going to be hectic and fun.

I will documents my steps (and missteps) so that it may be useful to some of you wishing to embark in similar projects

Next step: lots of dowels cutting, sanding and assembling.

FIRST UPDATE

I. Working on the bottom plate.

I decided to work on the bottom plate first, as a way to identify potential issue and improve things before I work on the top plate which will obvious be much more visible.

The idea is to intertwine square dowels which will create more rigidity than just carving square holes in a sheet of wood (especially for the top plate which will support the monitor.

Cutting

The bottom plate is assembled from a set of 11.5" and 9.5" dowels.

Here is a first rough layout before grooves are carved.

I used Inventable Easel (free version) to design the grooves and generate the Gcode.

CNC baby!!! (carving grooves in 11.5" dowels, 9 at a time)

This was my first cut just after the models presented by Sainsmart.

- I used A Dremel 654 1/4" Straight Routing Bit: with it's 1/8" shank it works well with the collet included with the 3018 by default, but make the job much faster than with a 1/8" bit, it seems to work will on these poplar dowels.

- Dowels are fixed to the spoilboard with the painter tape + superglue trick.

- compared to usual wood CNC works I don't cut full pieces from a plain wood stock... this requires quite some precision in the alignment of the origin, which proved to be tricky...

- also considering that the carving area is actually a bit less wide than 30cm due to limit stoppers... I had to have a second pass for the last groove... with risks of alignment inconsistencies. Thinking twice a larger CNC would have been a better choice but there is quite a price bump past the 3018, as they come with more than just a bigger frame (more powerful motors etc...). I will at least probably buy the 3040 extension kit for 3018 from Sainsmart or make my own soon.

- appart from alignment consistency, one thing i did not think about at all was tolerance, especially for grooves... Down the line, this required quite a lot of filing and sanding to adjust everything.

- this was all the more real as these dowels come with slight discrepencies in thickness are sometimes not perfectly straight. Grain is very random too.

The bottom plate after grooves are cut, and rough sanding/filing.

I will attach the side dowels later on as the basically lock everything in place, then apply a bit of wood filler on some spots and sand more.

The objective throughout this build is to avoid the wooden look and feel, so sanding is going to be long.

Next step: working on wooden side pannels, mostly a mitter saw job.

Last edited: