- Joined

- Sep 2, 2009

- Messages

- 125 (0.02/day)

- Location

- New Hampshire, USA

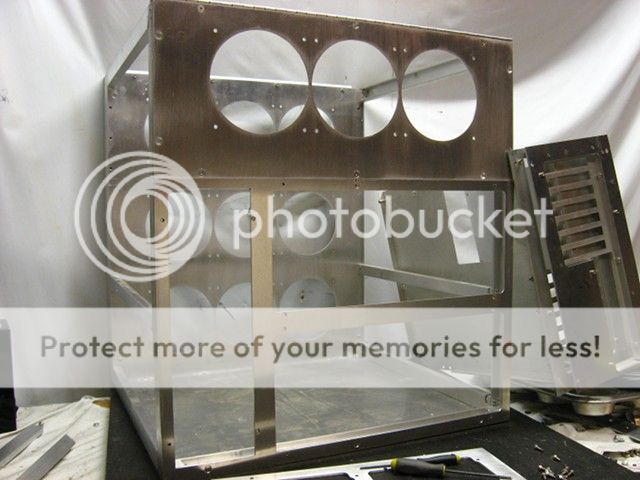

The hinge for the top was cut slightly undersized and centered with a some old business cards used as spacers.

Dimples of aluminum had to be removed from the frame in order to make room for the nuts holding the top sheet to the hinge.

With only a 2.5mm gap between the leaves of the hinge, button head cap screws were used to attach the hinge to the frame.

The hinge aligns perfectly with the top sheet, which in turn aligns with the back sheet.

Dimples of aluminum had to be removed from the frame in order to make room for the nuts holding the top sheet to the hinge.

With only a 2.5mm gap between the leaves of the hinge, button head cap screws were used to attach the hinge to the frame.

The hinge aligns perfectly with the top sheet, which in turn aligns with the back sheet.

Looking forward to more pics!

Looking forward to more pics!