- Joined

- Jan 5, 2006

- Messages

- 18,584 (2.63/day)

| System Name | AlderLake |

|---|---|

| Processor | Intel i7 12700K P-Cores @ 5Ghz |

| Motherboard | Gigabyte Z690 Aorus Master |

| Cooling | Noctua NH-U12A 2 fans + Thermal Grizzly Kryonaut Extreme + 5 case fans |

| Memory | 32GB DDR5 Corsair Dominator Platinum RGB 6000MT/s CL36 |

| Video Card(s) | MSI RTX 2070 Super Gaming X Trio |

| Storage | Samsung 980 Pro 1TB + 970 Evo 500GB + 850 Pro 512GB + 860 Evo 1TB x2 |

| Display(s) | 23.8" Dell S2417DG 165Hz G-Sync 1440p |

| Case | Be quiet! Silent Base 600 - Window |

| Audio Device(s) | Panasonic SA-PMX94 / Realtek onboard + B&O speaker system / Harman Kardon Go + Play / Logitech G533 |

| Power Supply | Seasonic Focus Plus Gold 750W |

| Mouse | Logitech MX Anywhere 2 Laser wireless |

| Keyboard | RAPOO E9270P Black 5GHz wireless |

| Software | Windows 11 |

| Benchmark Scores | Cinebench R23 (Single Core) 1936 @ stock Cinebench R23 (Multi Core) 23006 @ stock |

Some interesting stuff:

For decades, hopeful techies have been promising a world where absolutely every object you encounter—bandages, bottles, bananas—will have some kind of smarts thanks to supercheap programmable plastic processors. If you’ve been wondering why that hasn’t happened yet, it’s that nobody has built working processors that can be made in the billions for less than a penny each.

It hasn’t been for want of trying; in 2021 Arm reproduced its simplest 32-bit microcontroller, the M0, in plastic, but even this couldn’t hope to meet the mark. The problem, according to engineers at the University of Illinois Urbana-Champaign and at British flexible-electronics manufacture PragmatIC Semiconductor, is that even the simplest industry-standard microcontrollers are too complex to make on plastic in bulk.

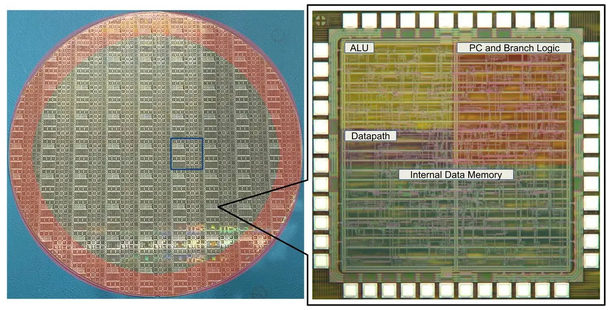

In research to be presented at the International Symposium on Computer Architecture later this month, the transatlantic team presents a simple yet fully functional plastic processor that could be made at sub-penny prices. The Illinois team designed 4-bit and 8-bit processors specifically to minimize size and maximize the percentage of working integrated circuits produced. Eighty-one percent of the 4-bit version worked, and that’s a good enough yield, says team leader Rakesh Kumar, to breach the one-penny barrier.

“Flexible electronics has been niche for decades,” says Kumar. He adds that this yield study shows “that they may be ready for the mainstream.”

The processors his team built were made using the flexible thin-film semiconductor indium gallium zinc oxide (IGZO), which can be built on plastic and continues to work even when bent around a radius of millimeters. But while a reliable manufacturing process is a prerequisite, it was the design that made the difference.

Over the next few days, the International Symposium on Computer Architecture will take place in New York. During this fair, the researchers will present Flexicore, which is expected to reveal more details.

Read more: https://spectrum.ieee.org/plastic-microprocessor

For decades, hopeful techies have been promising a world where absolutely every object you encounter—bandages, bottles, bananas—will have some kind of smarts thanks to supercheap programmable plastic processors. If you’ve been wondering why that hasn’t happened yet, it’s that nobody has built working processors that can be made in the billions for less than a penny each.

It hasn’t been for want of trying; in 2021 Arm reproduced its simplest 32-bit microcontroller, the M0, in plastic, but even this couldn’t hope to meet the mark. The problem, according to engineers at the University of Illinois Urbana-Champaign and at British flexible-electronics manufacture PragmatIC Semiconductor, is that even the simplest industry-standard microcontrollers are too complex to make on plastic in bulk.

In research to be presented at the International Symposium on Computer Architecture later this month, the transatlantic team presents a simple yet fully functional plastic processor that could be made at sub-penny prices. The Illinois team designed 4-bit and 8-bit processors specifically to minimize size and maximize the percentage of working integrated circuits produced. Eighty-one percent of the 4-bit version worked, and that’s a good enough yield, says team leader Rakesh Kumar, to breach the one-penny barrier.

“Flexible electronics has been niche for decades,” says Kumar. He adds that this yield study shows “that they may be ready for the mainstream.”

The processors his team built were made using the flexible thin-film semiconductor indium gallium zinc oxide (IGZO), which can be built on plastic and continues to work even when bent around a radius of millimeters. But while a reliable manufacturing process is a prerequisite, it was the design that made the difference.

Why Not Silicon?

You might be wondering why silicon processors can’t do the job of supercheap flexible computing. Kumar’s analysis suggest it won’t work. Compared to plastic, silicon is expensive and inflexible, but if you make the chip small enough, the plastic can just bend around it. However, silicon fails at the task for two reasons: One is that although the area of circuitry could be made supersmall, you still need to leave a comparatively large amount of space around the edges so that the chip can be cut out of the wafer. In the case of a microcontroller as simple as the Flexicore, there would be more space around the edge than there is area containing circuitry. What’s more, you’ll need still more room to fit enough I/O pads so data and power can get to the chip. Suddenly, you’ve got a large area of costly blank silicon, pushing up expenses past the critical US $0.01 mark.Over the next few days, the International Symposium on Computer Architecture will take place in New York. During this fair, the researchers will present Flexicore, which is expected to reveal more details.

Read more: https://spectrum.ieee.org/plastic-microprocessor

Last edited: