- Joined

- Dec 14, 2013

- Messages

- 2,762 (0.66/day)

- Location

- Alabama

| Processor | Ryzen 2600 |

|---|---|

| Motherboard | X470 Tachi Ultimate |

| Cooling | AM3+ Wraith CPU cooler |

| Memory | C.R.S. |

| Video Card(s) | GTX 970 |

| Software | Linux Peppermint 10 |

| Benchmark Scores | Never high enough |

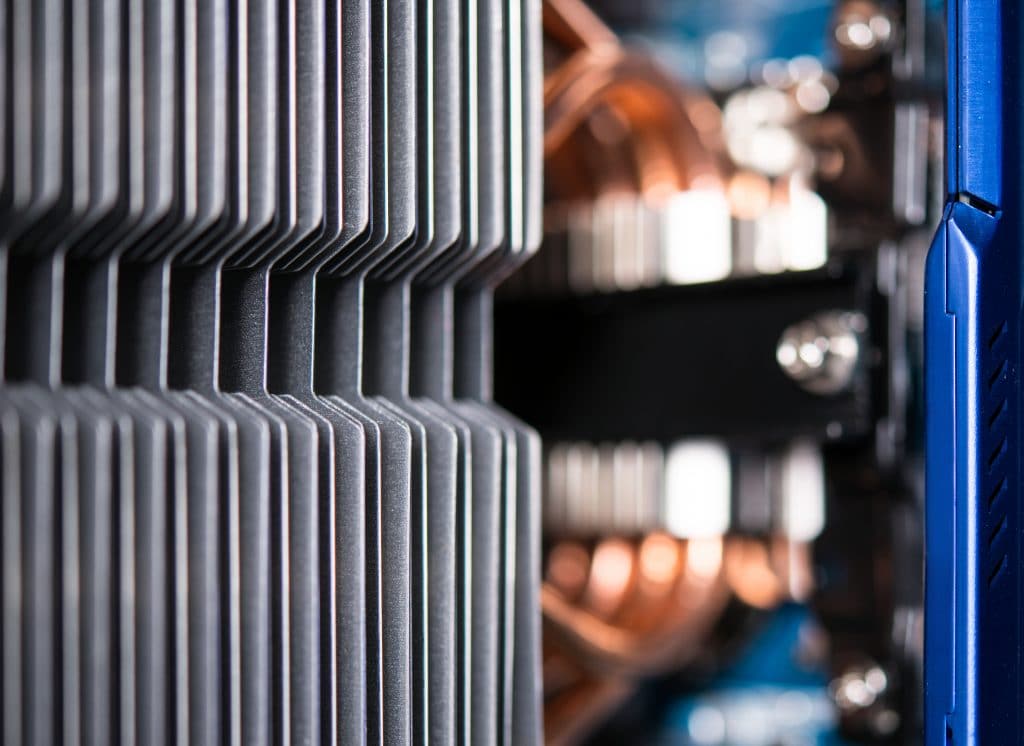

It may or may not still be there but much, if not most of the heatsinks themselves will at least show alot of damage due to contact with the stuff.I was referring to people who use it normally, like a PS5 system for example. Open a PS5 in 40 years, and it will still be liquid in form. I'd bet money on it anyway, but yes if I knew we were talking about idiots who combine it with metals they shouldn't, my answer would have been different, lol

I'm willing to bet at least some PS5's you see up for grabs on fleabay with symptoms due to overheating have this problem, similar to the PS3 "LED's of death" that also being due to overheating.

If I ever get a PS5, LM removal and heatsink inspection/cleaning/repair will be the first thing I do and I don't care if it's new or used.