- Joined

- Oct 9, 2007

- Messages

- 47,676 (7.43/day)

- Location

- Dublin, Ireland

| System Name | RBMK-1000 |

|---|---|

| Processor | AMD Ryzen 7 5700G |

| Motherboard | Gigabyte B550 AORUS Elite V2 |

| Cooling | DeepCool Gammax L240 V2 |

| Memory | 2x 16GB DDR4-3200 |

| Video Card(s) | Galax RTX 4070 Ti EX |

| Storage | Samsung 990 1TB |

| Display(s) | BenQ 1440p 60 Hz 27-inch |

| Case | Corsair Carbide 100R |

| Audio Device(s) | ASUS SupremeFX S1220A |

| Power Supply | Cooler Master MWE Gold 650W |

| Mouse | ASUS ROG Strix Impact |

| Keyboard | Gamdias Hermes E2 |

| Software | Windows 11 Pro |

TSMC today introduced its N4X process technology, tailored for the demanding workloads of high performance computing (HPC) products. N4X is the first of TSMC's HPC-focused technology offerings, representing ultimate performance and maximum clock frequencies in the 5-nanometer family. The "X" designation is reserved for TSMC technologies that are developed specifically for HPC products.

"HPC is now TSMC's fastest-growing business segment and we are proud to introduce N4X, the first in the 'X' lineage of our extreme performance semiconductor technologies," said Dr. Kevin Zhang, senior vice president of Business Development at TSMC. "The demands of the HPC segment are unrelenting, and TSMC has not only tailored our 'X' semiconductor technologies to unleash ultimate performance but has also combined it with our 3DFabric advanced packaging technologies to offer the best HPC platform."

Leveraging its experience in 5 nm volume production, TSMC further enhanced its technology with features ideal for high performance computing products to create N4X. These features include:

For more information, visit this page.

View at TechPowerUp Main Site

"HPC is now TSMC's fastest-growing business segment and we are proud to introduce N4X, the first in the 'X' lineage of our extreme performance semiconductor technologies," said Dr. Kevin Zhang, senior vice president of Business Development at TSMC. "The demands of the HPC segment are unrelenting, and TSMC has not only tailored our 'X' semiconductor technologies to unleash ultimate performance but has also combined it with our 3DFabric advanced packaging technologies to offer the best HPC platform."

Leveraging its experience in 5 nm volume production, TSMC further enhanced its technology with features ideal for high performance computing products to create N4X. These features include:

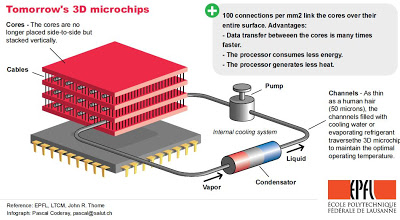

- Device design and structures optimized for high drive current and maximum frequency

- Back-end metal stack optimization for high-performance designs

- Super high density metal-insulator-metal capacitors for robust power delivery under extreme performance loads

- These HPC features will enable N4X to offer a performance boost of up to 15% over N5, or up to 4% over the even faster N4P at 1.2 volt. N4X can achieve drive voltages beyond 1.2 volt and deliver additional performance. Customers can also draw on the common design rules of the N5 process to accelerate the development of their N4X products. TSMC expects N4X to enter risk production by the first half of 2023.

For more information, visit this page.

View at TechPowerUp Main Site