- Joined

- Feb 3, 2018

- Messages

- 257 (0.09/day)

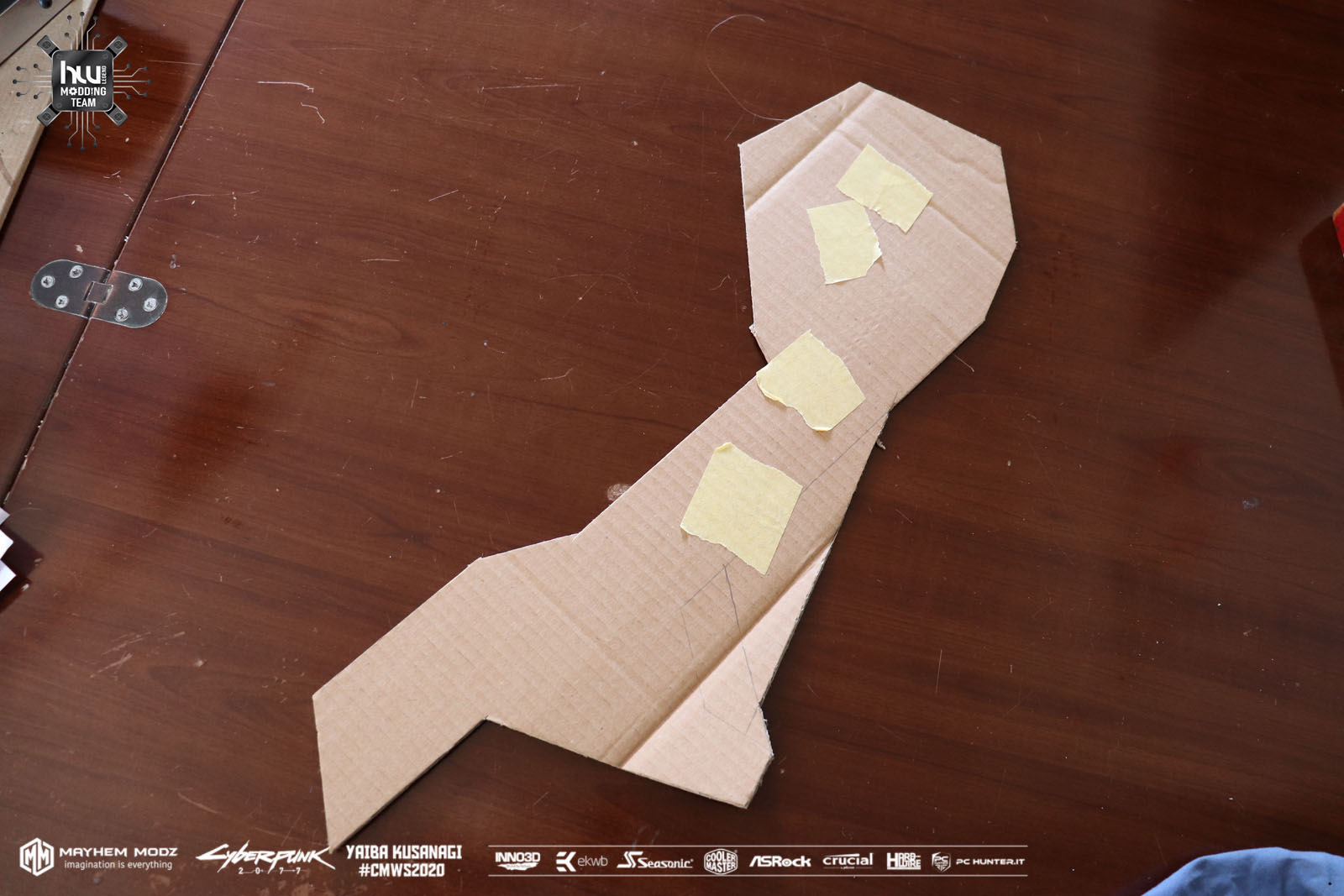

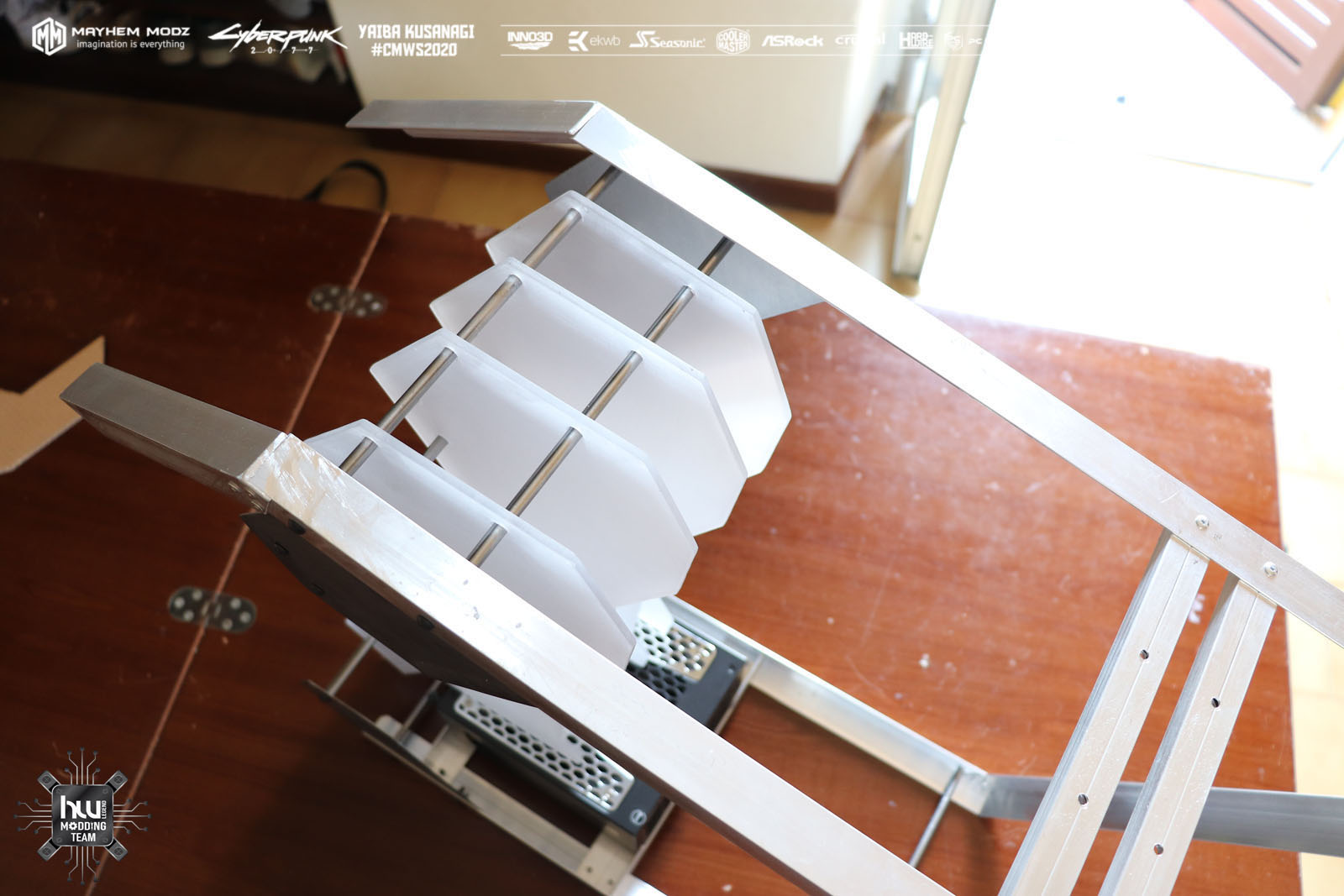

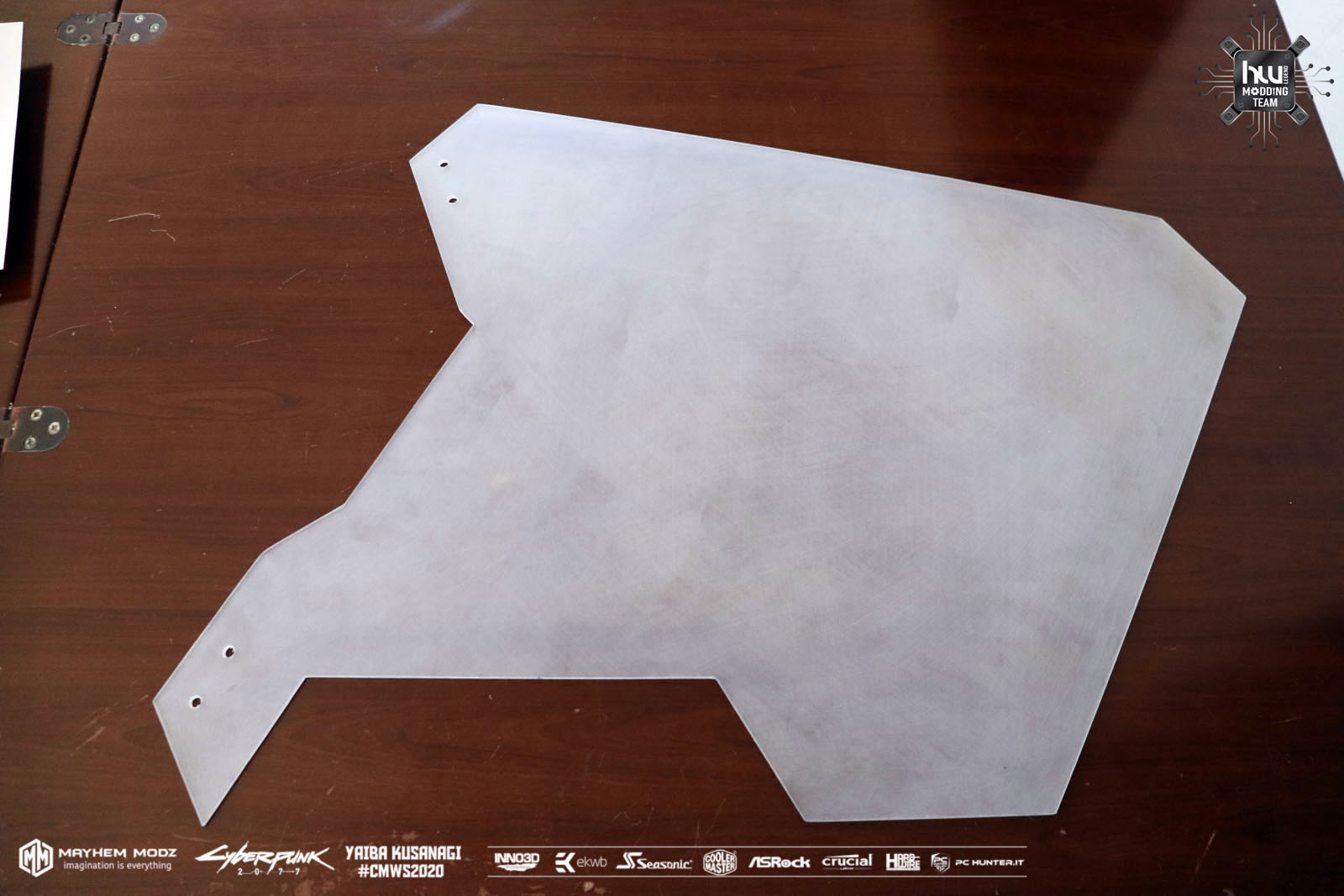

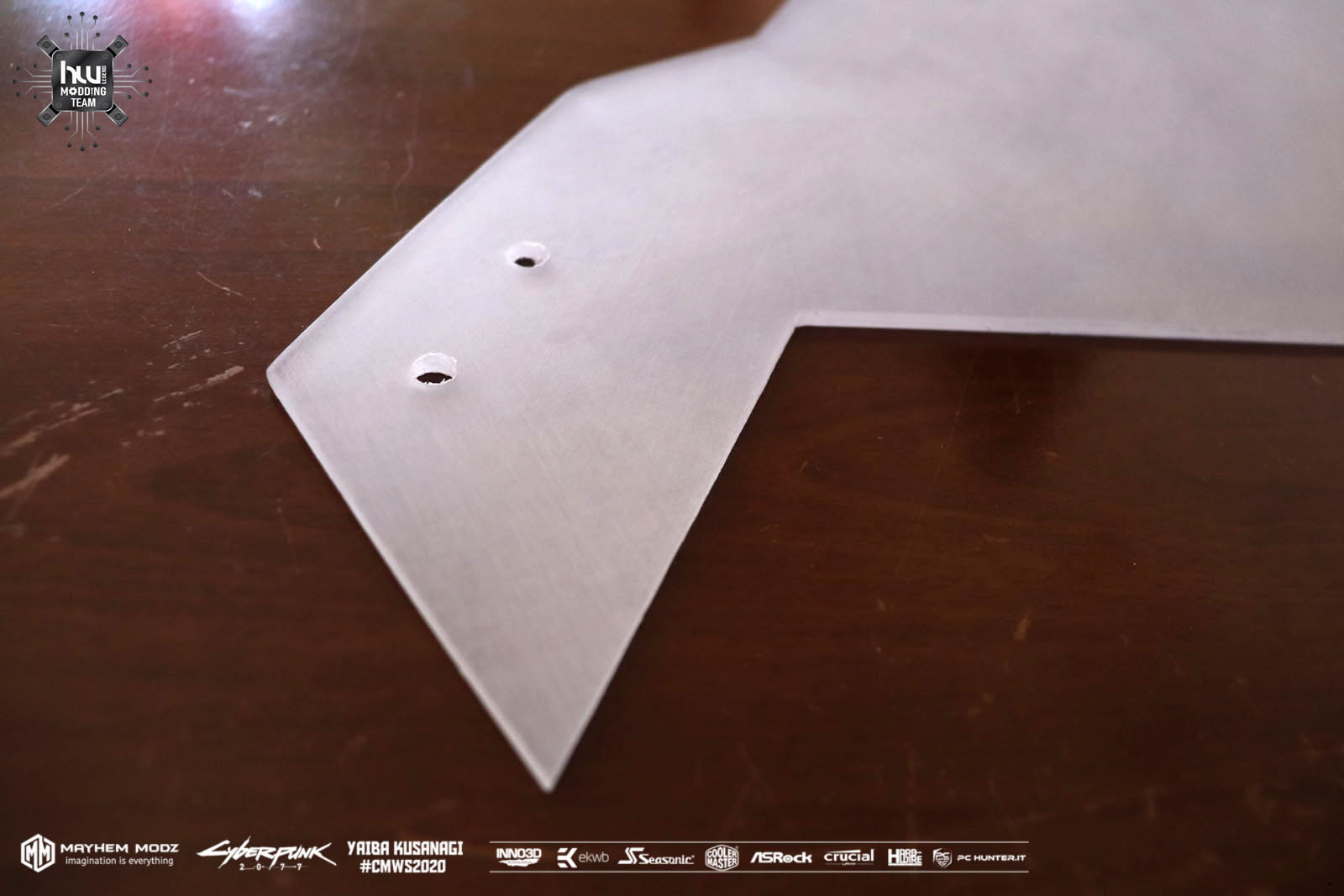

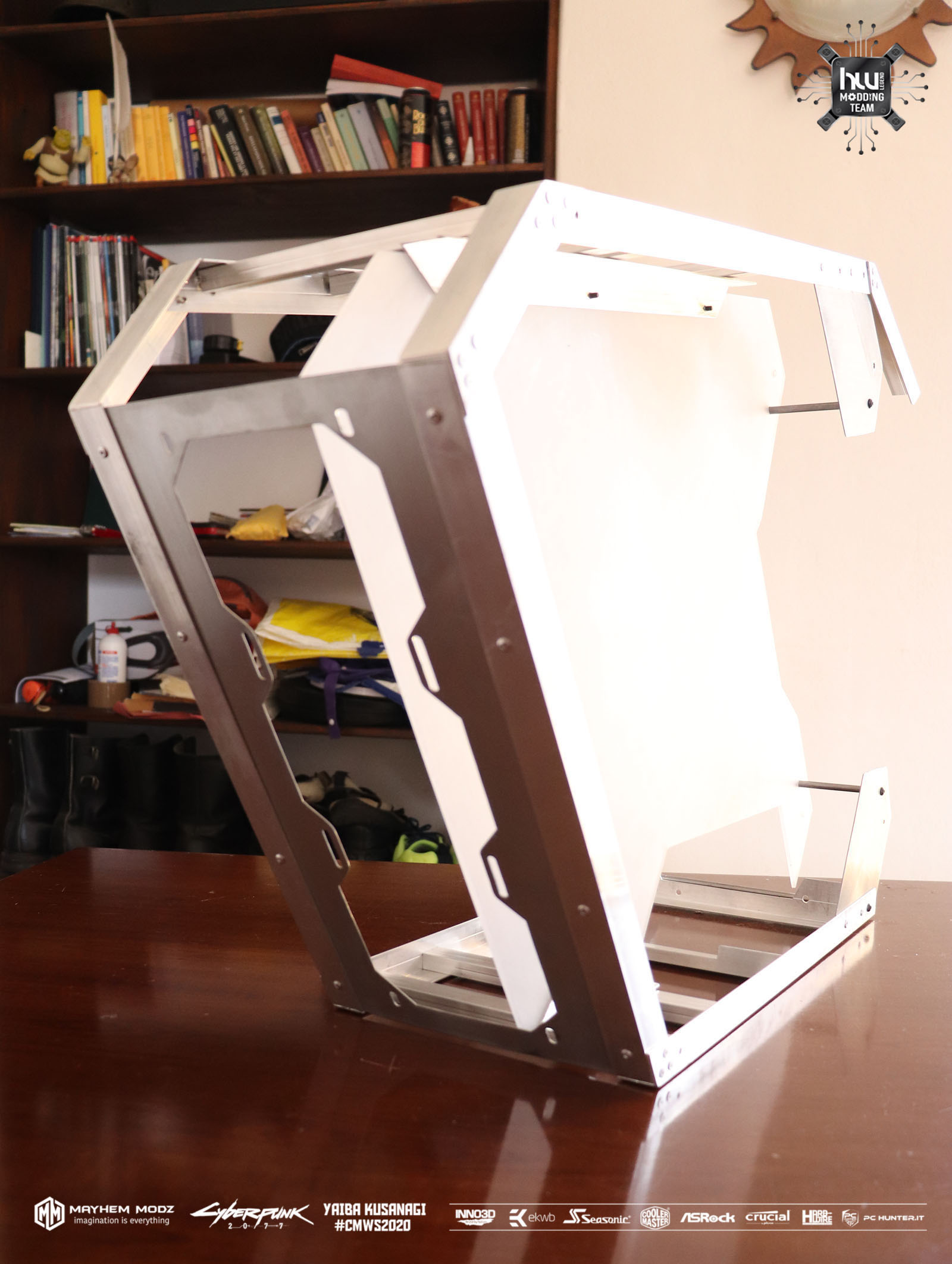

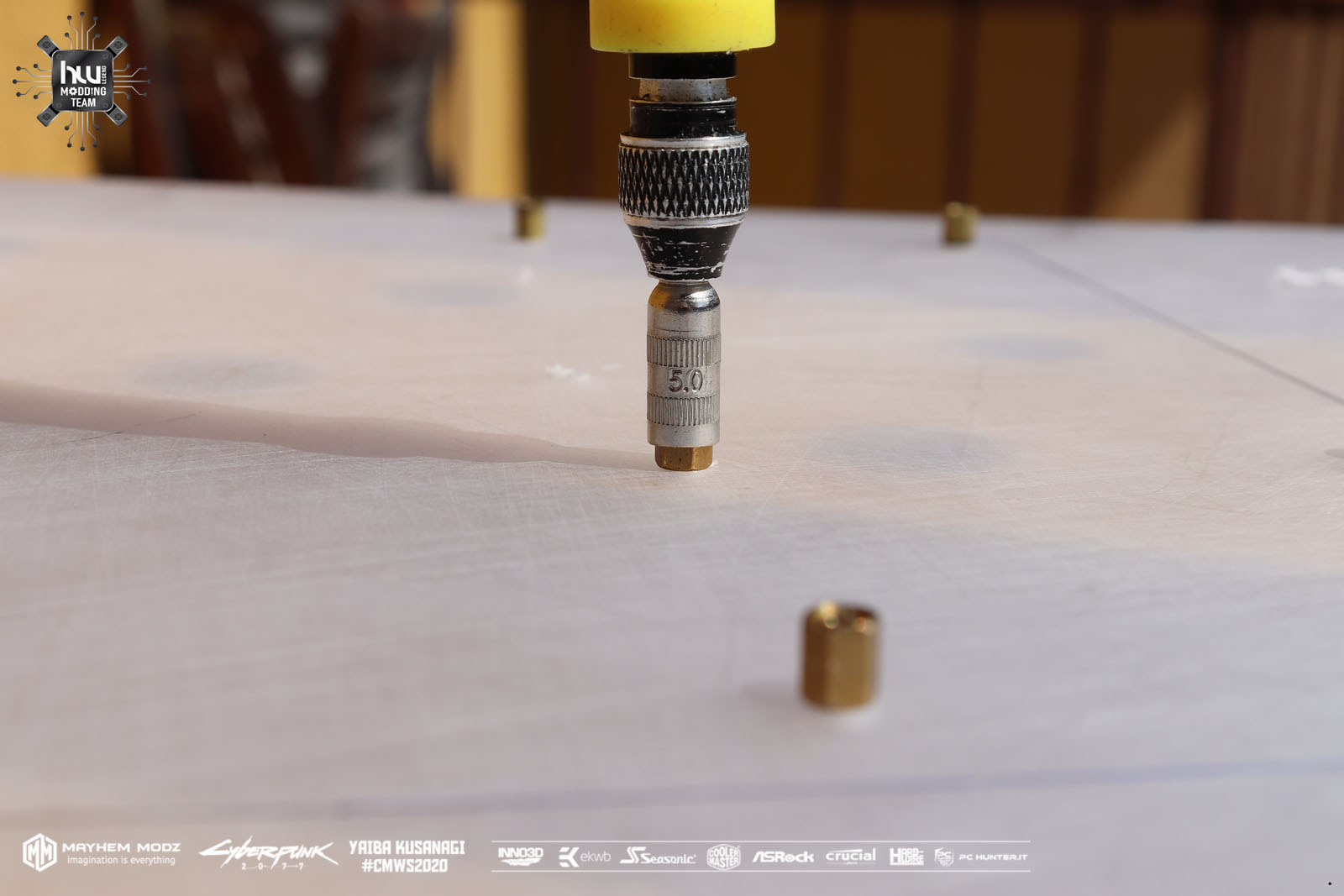

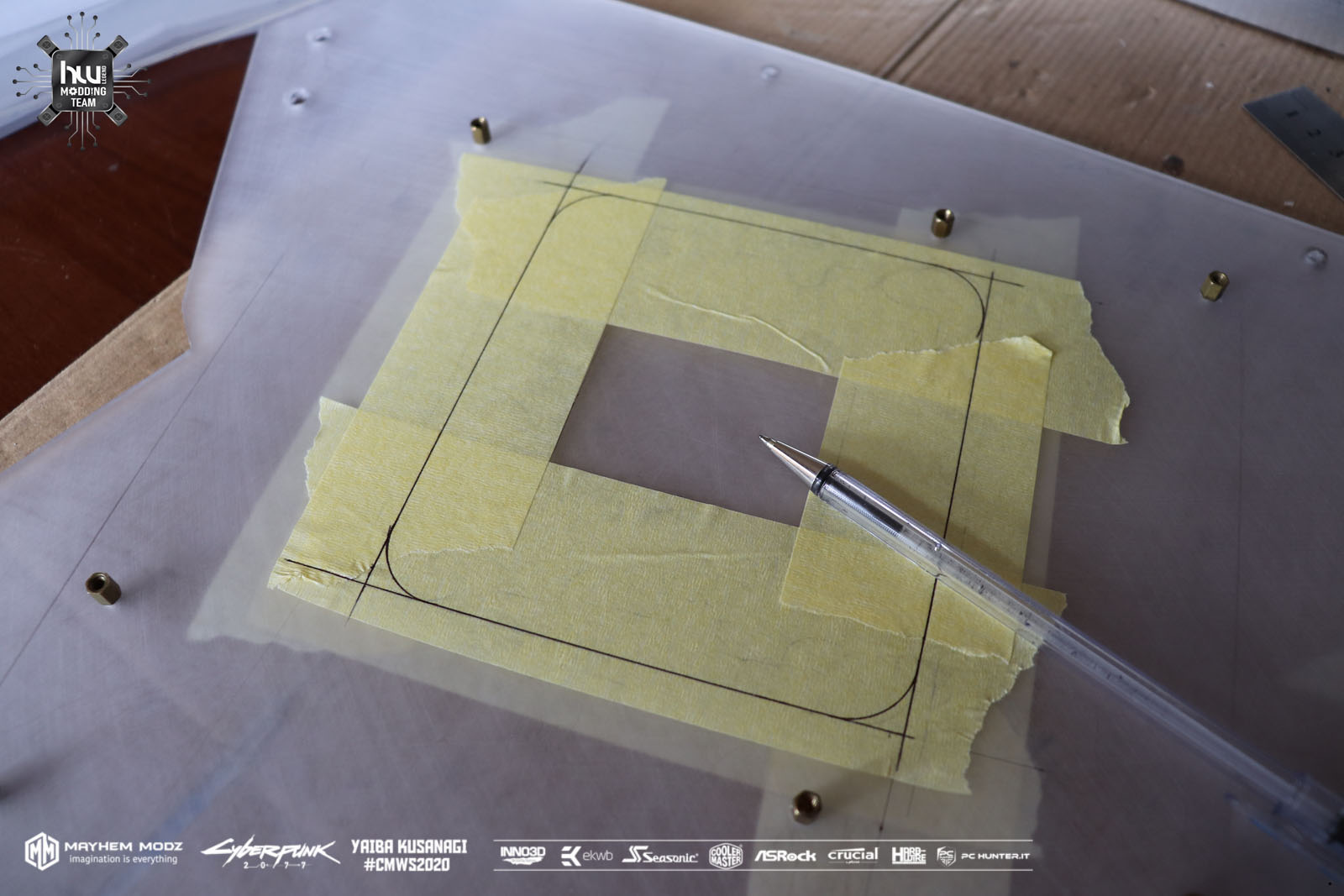

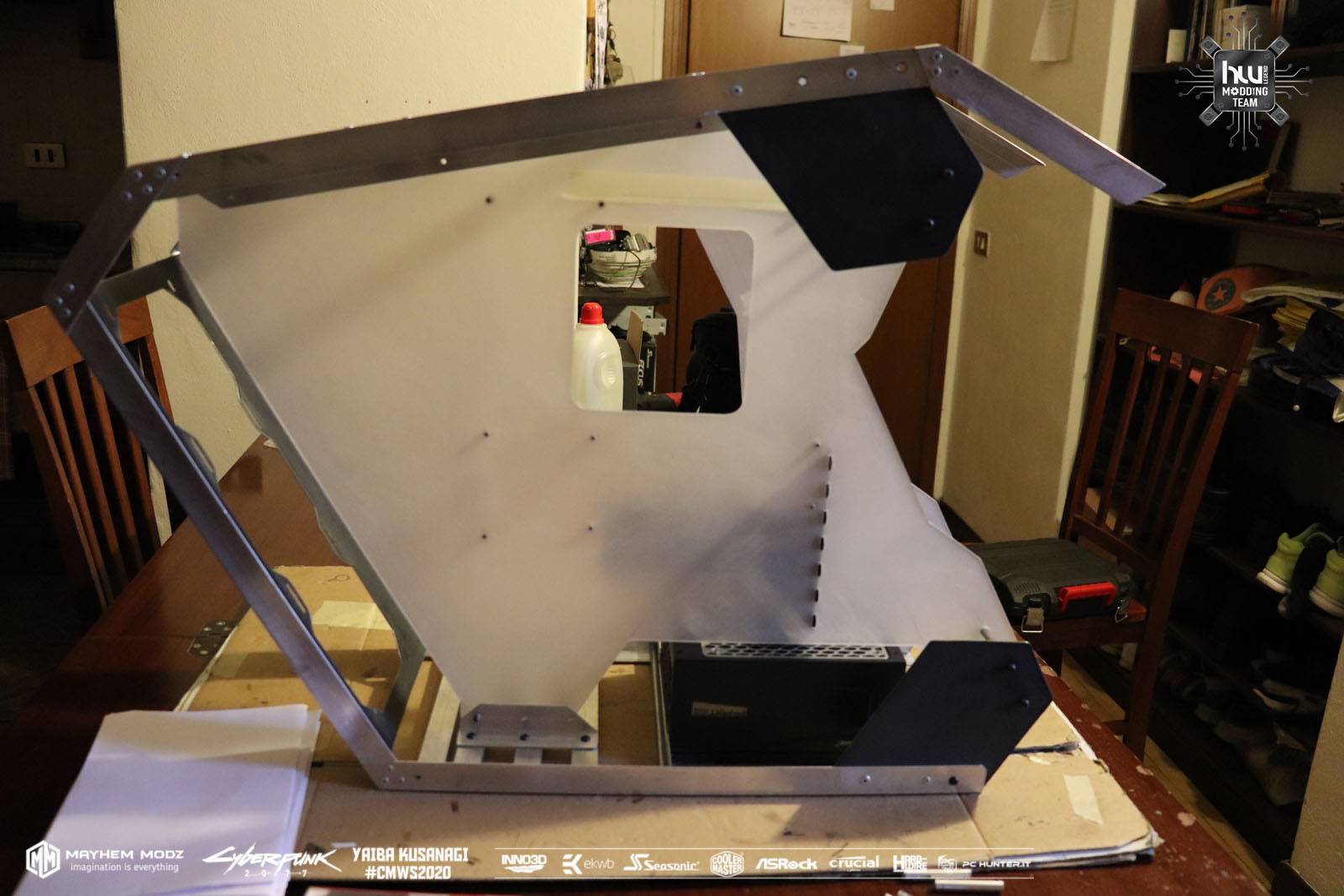

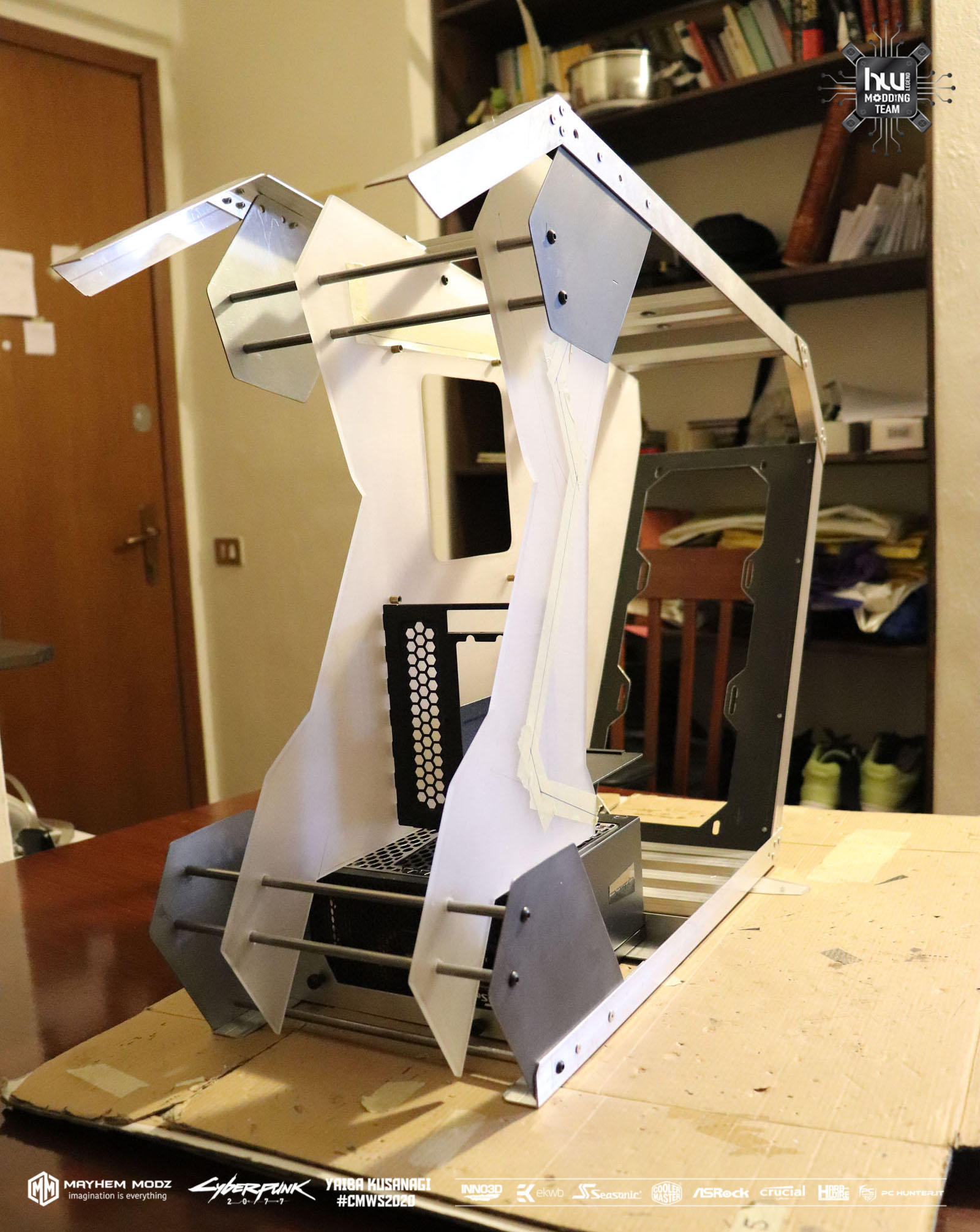

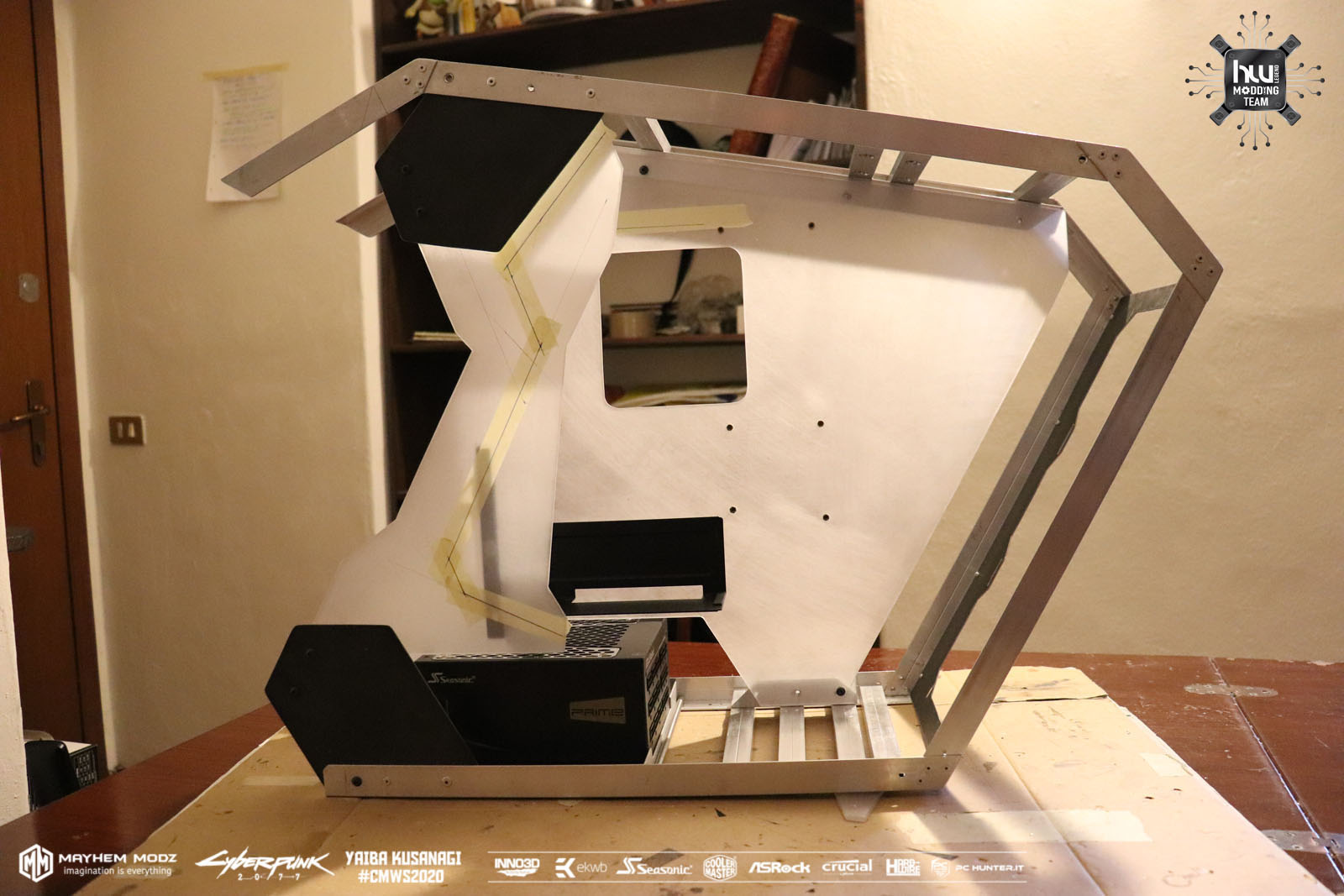

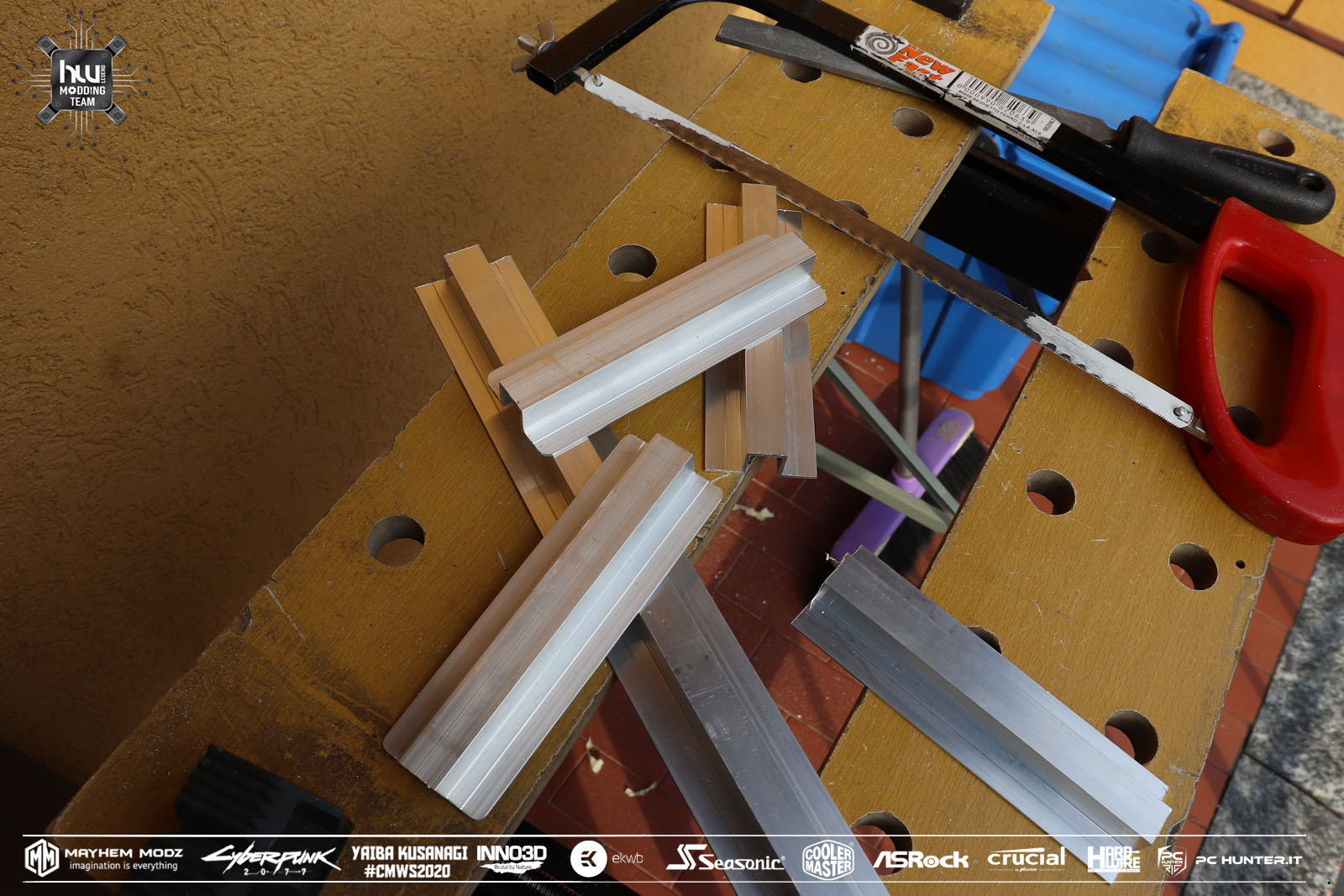

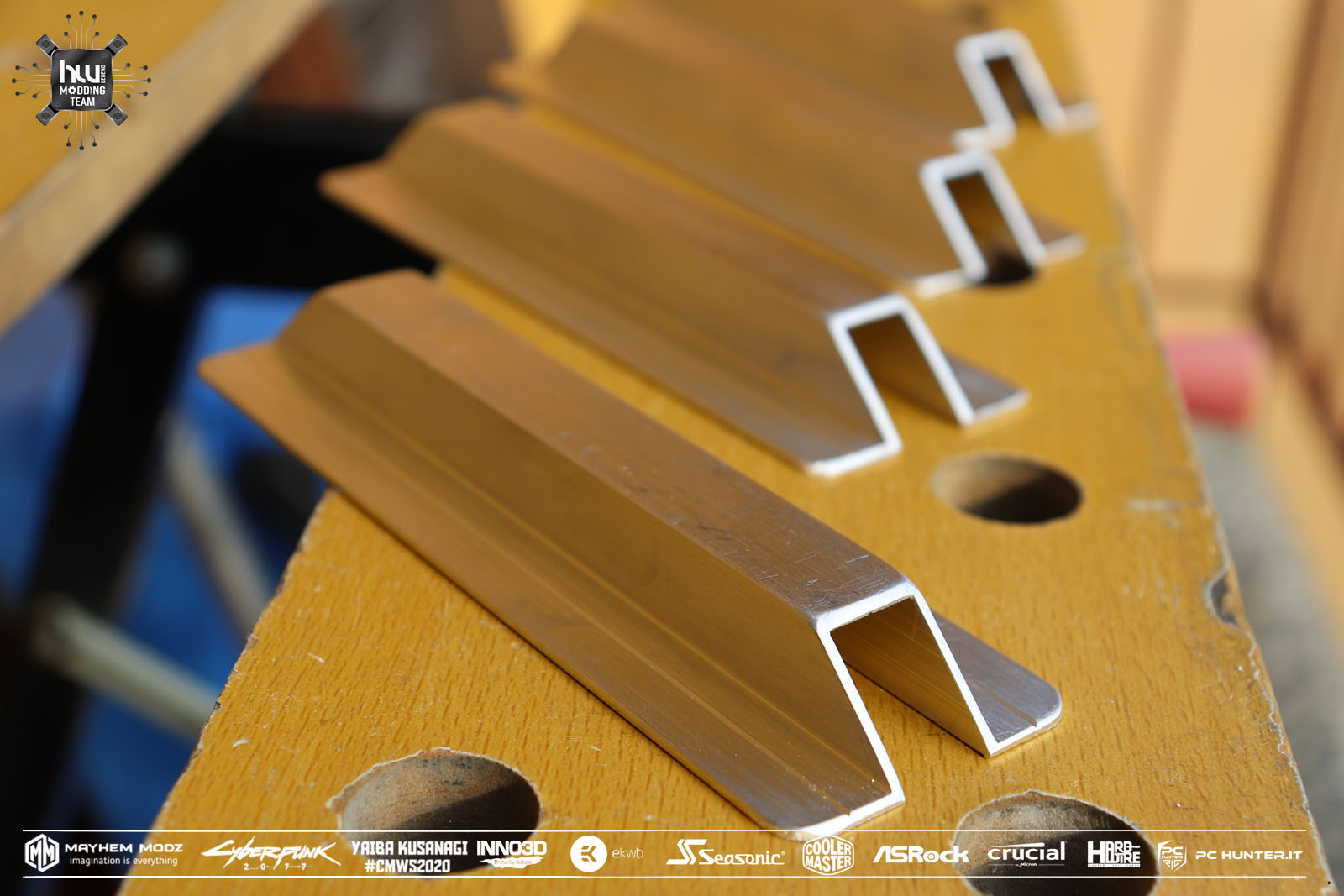

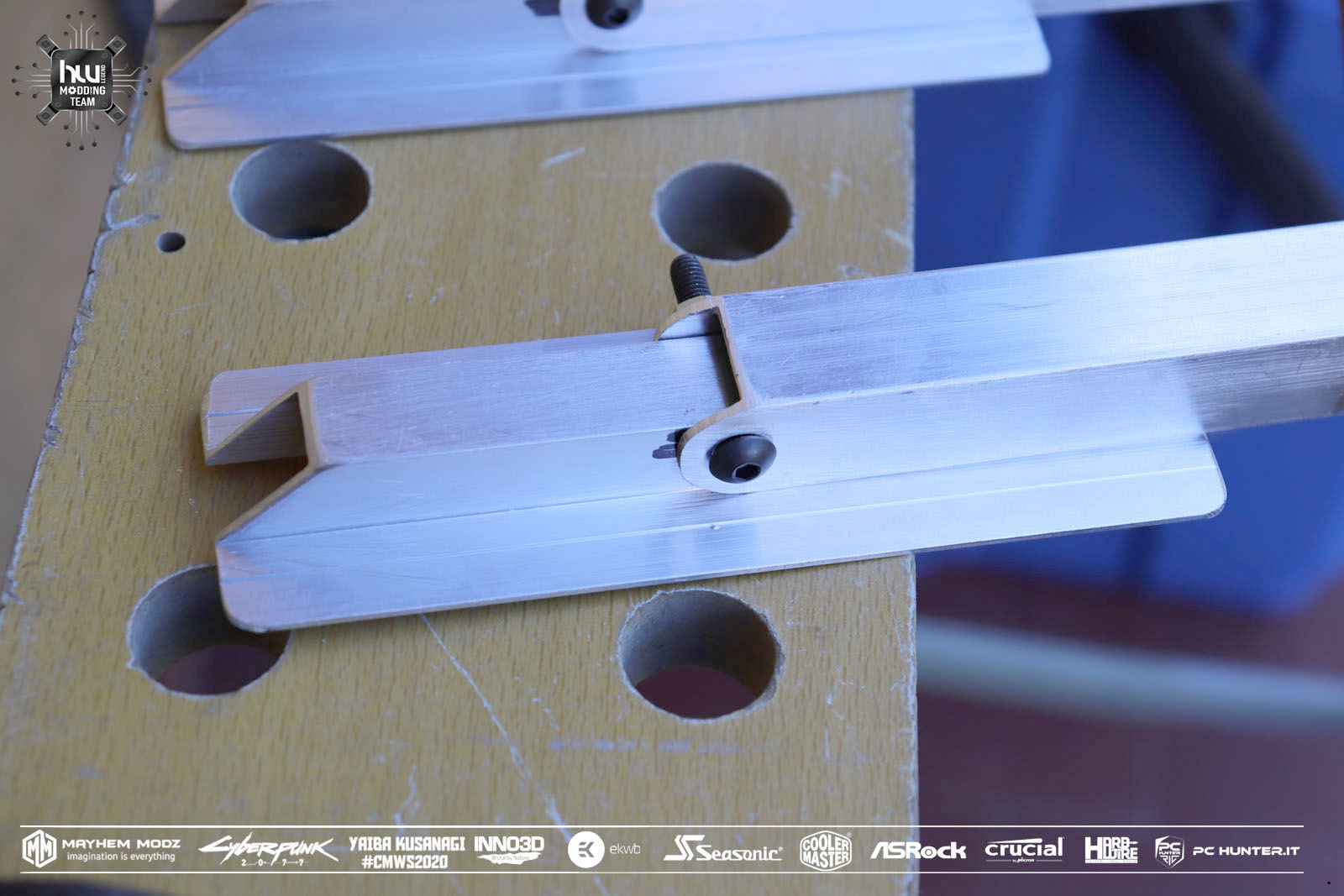

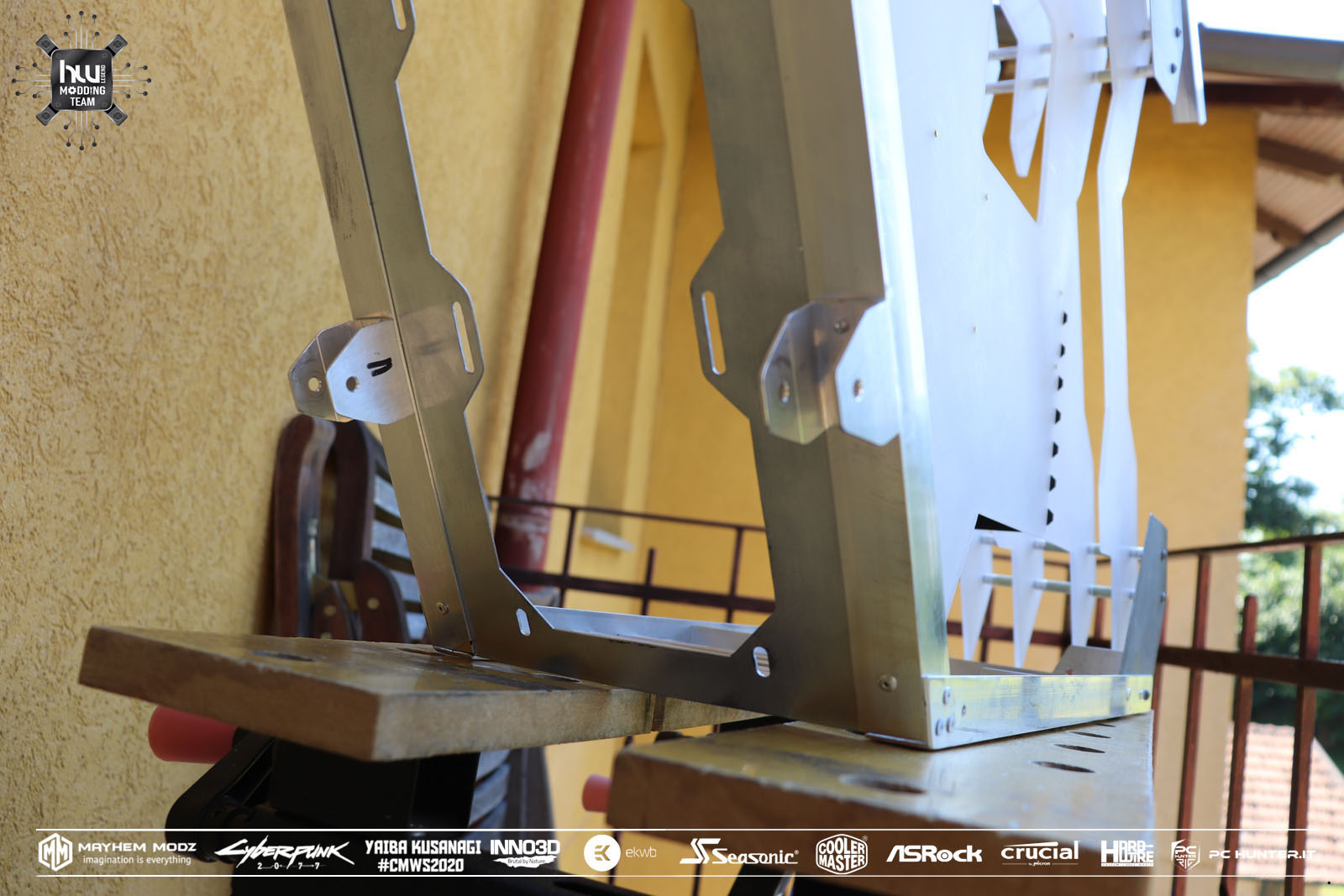

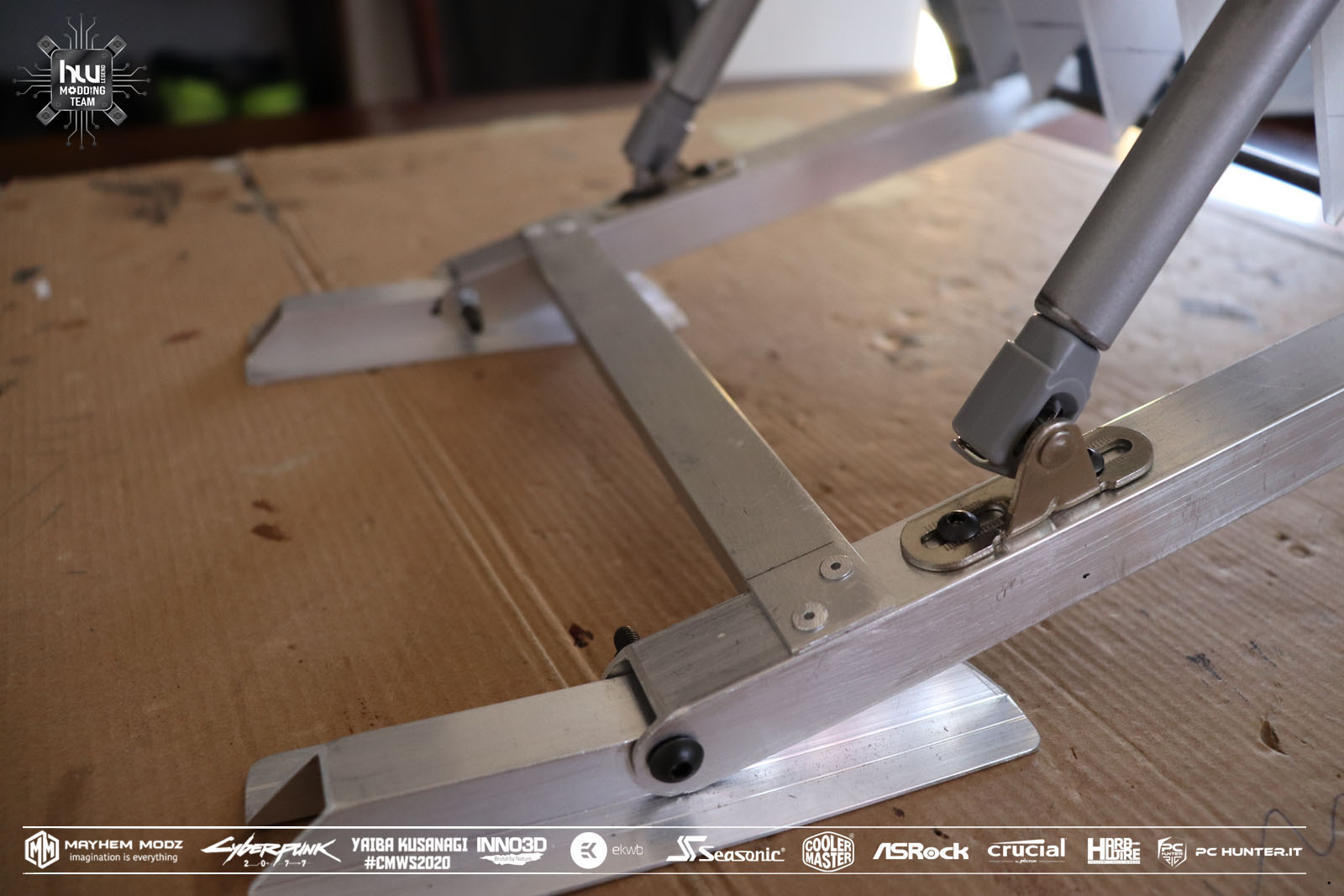

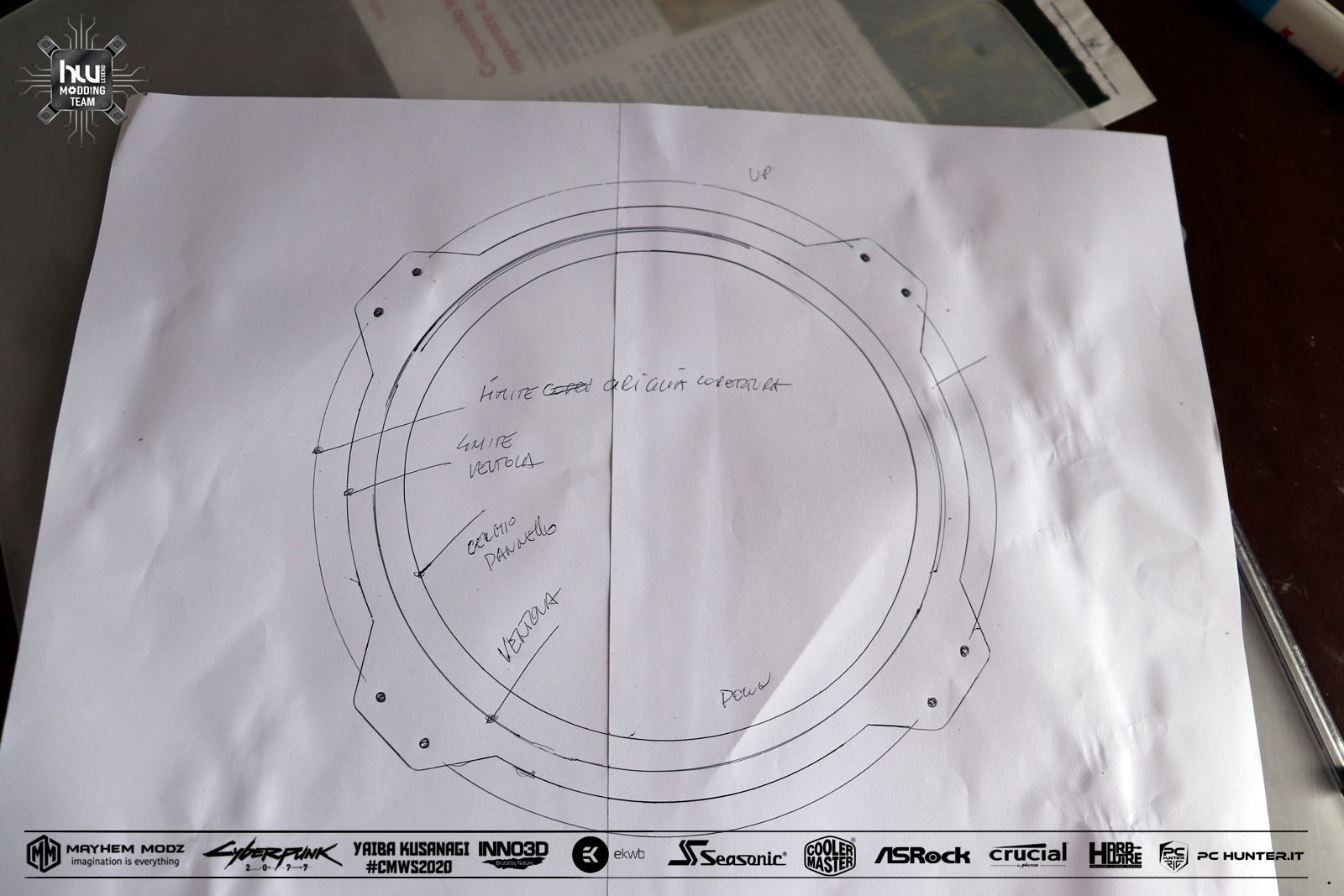

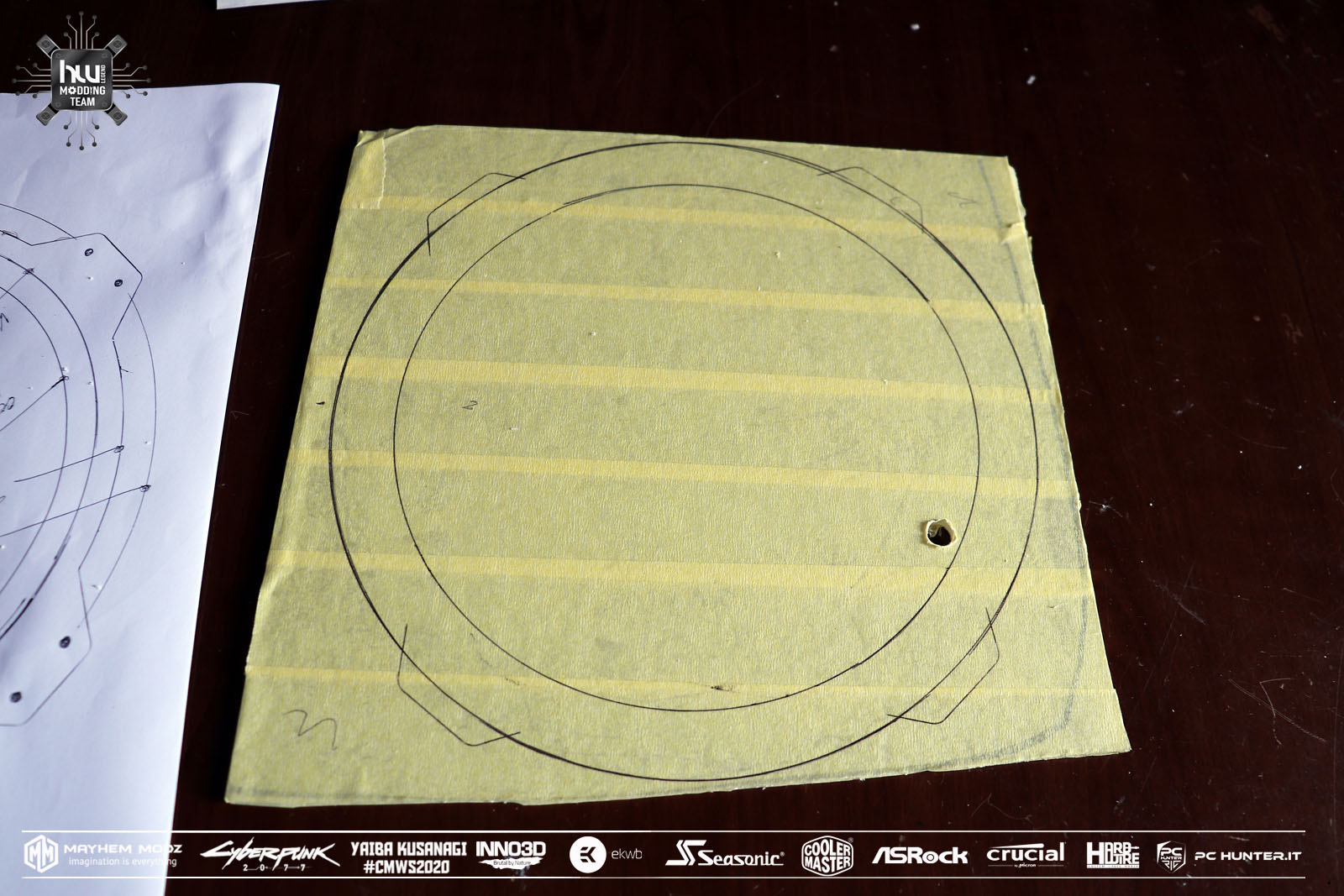

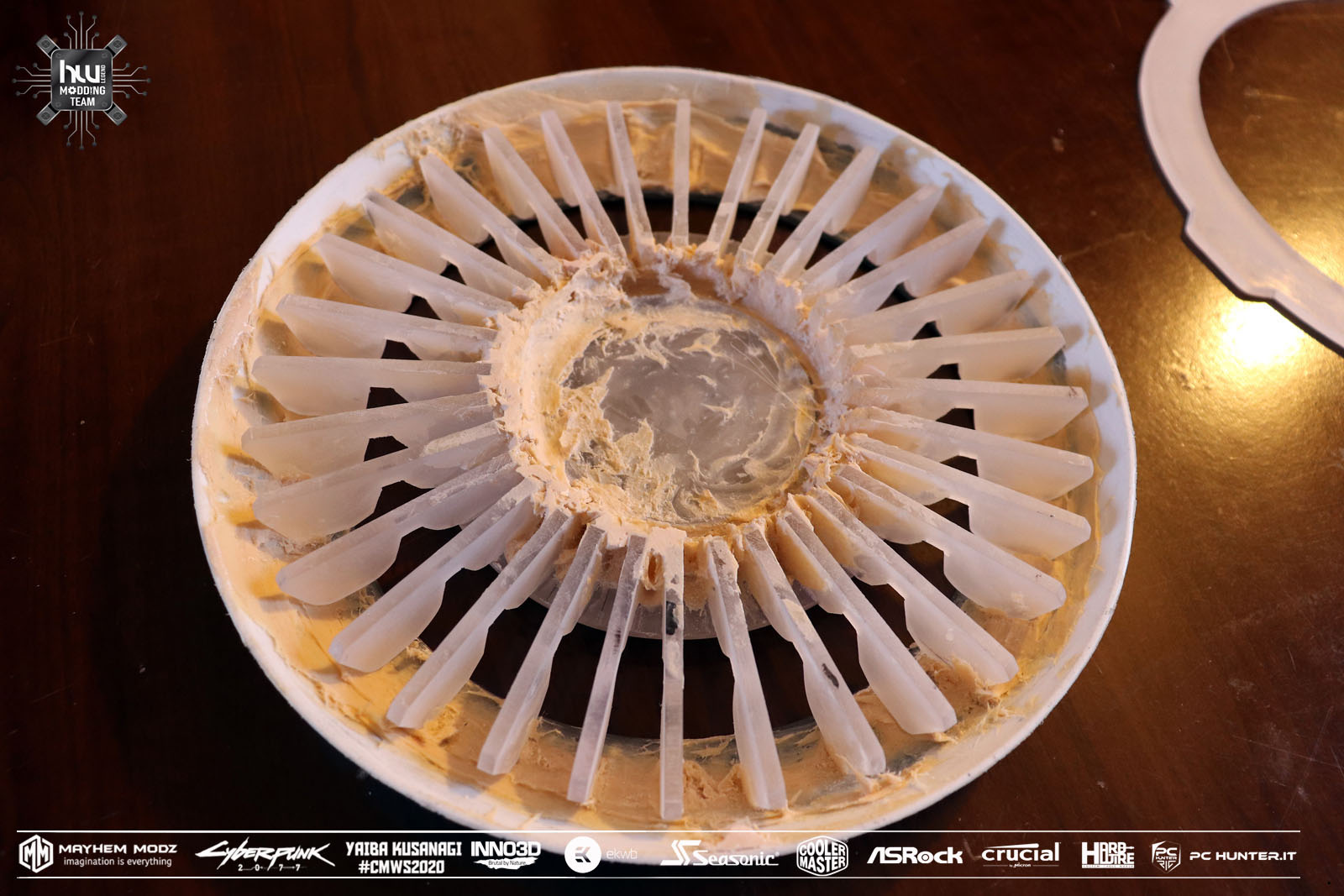

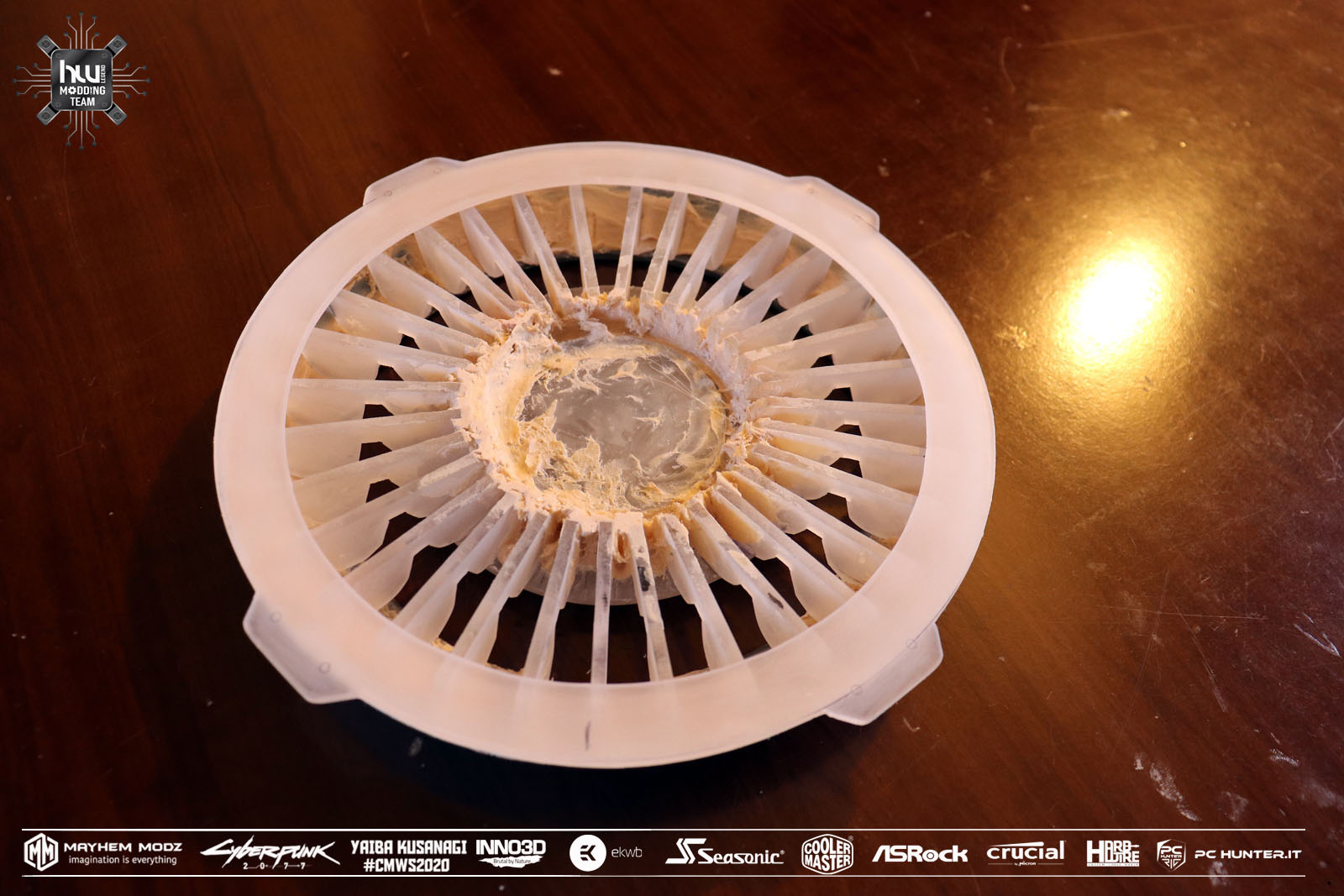

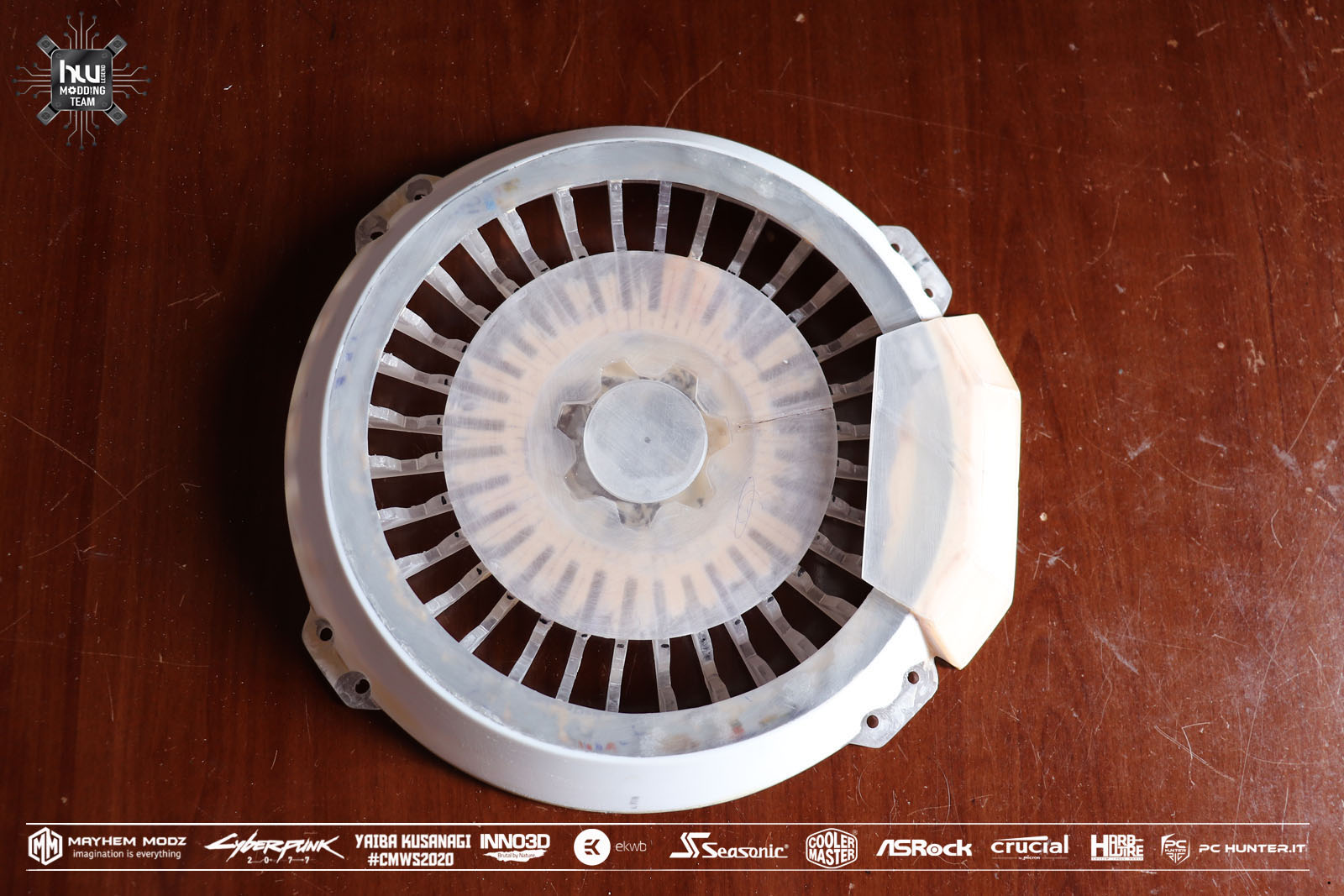

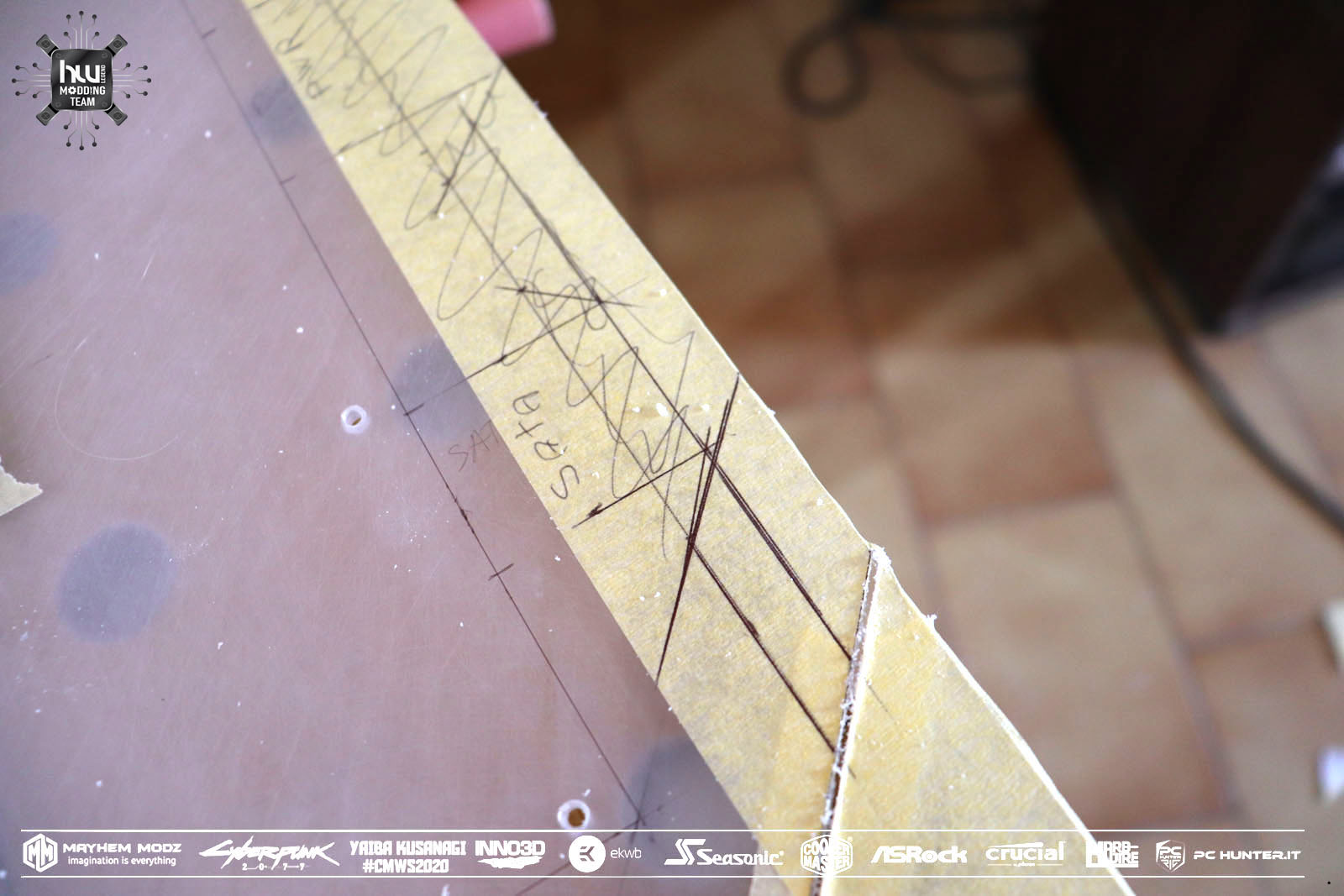

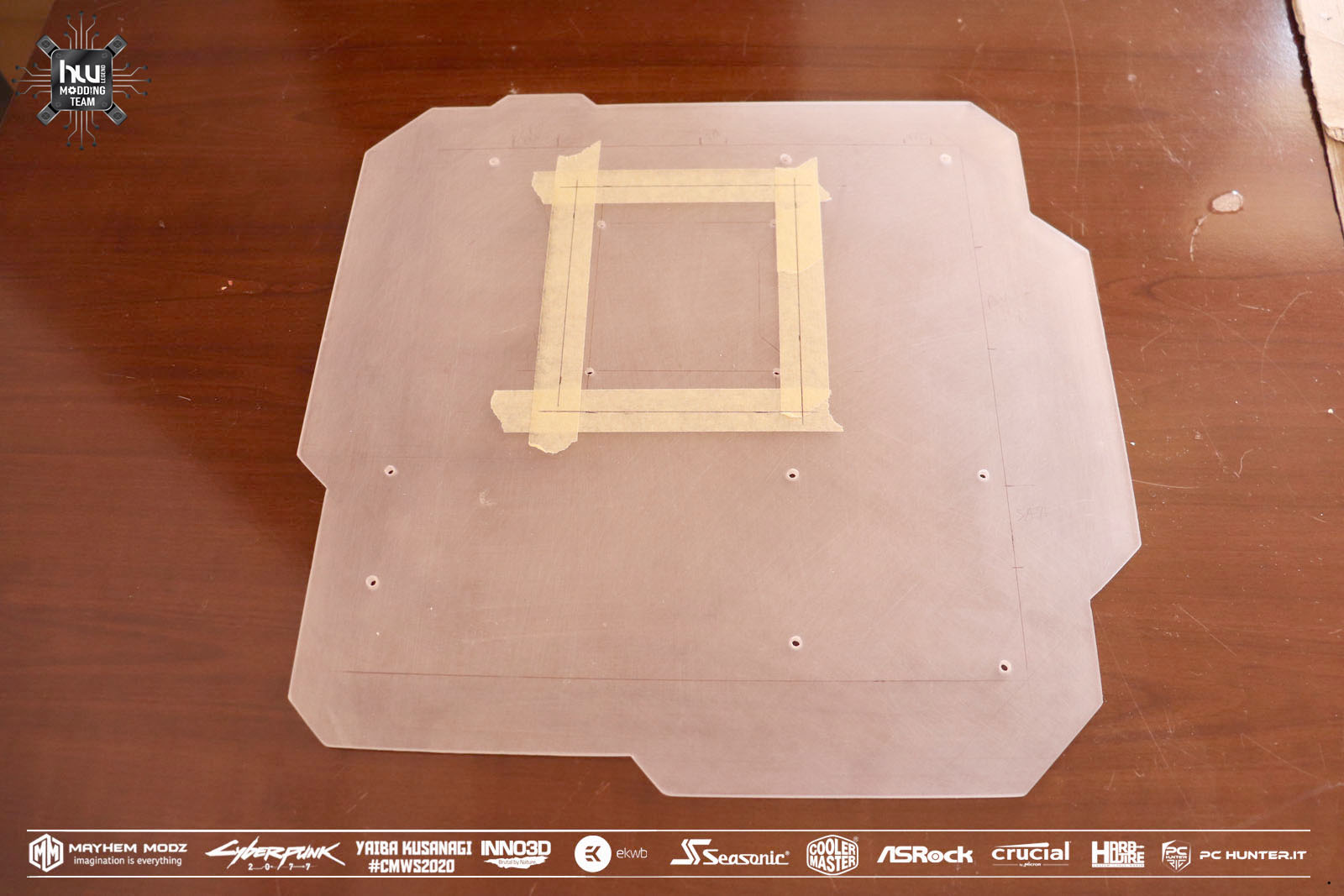

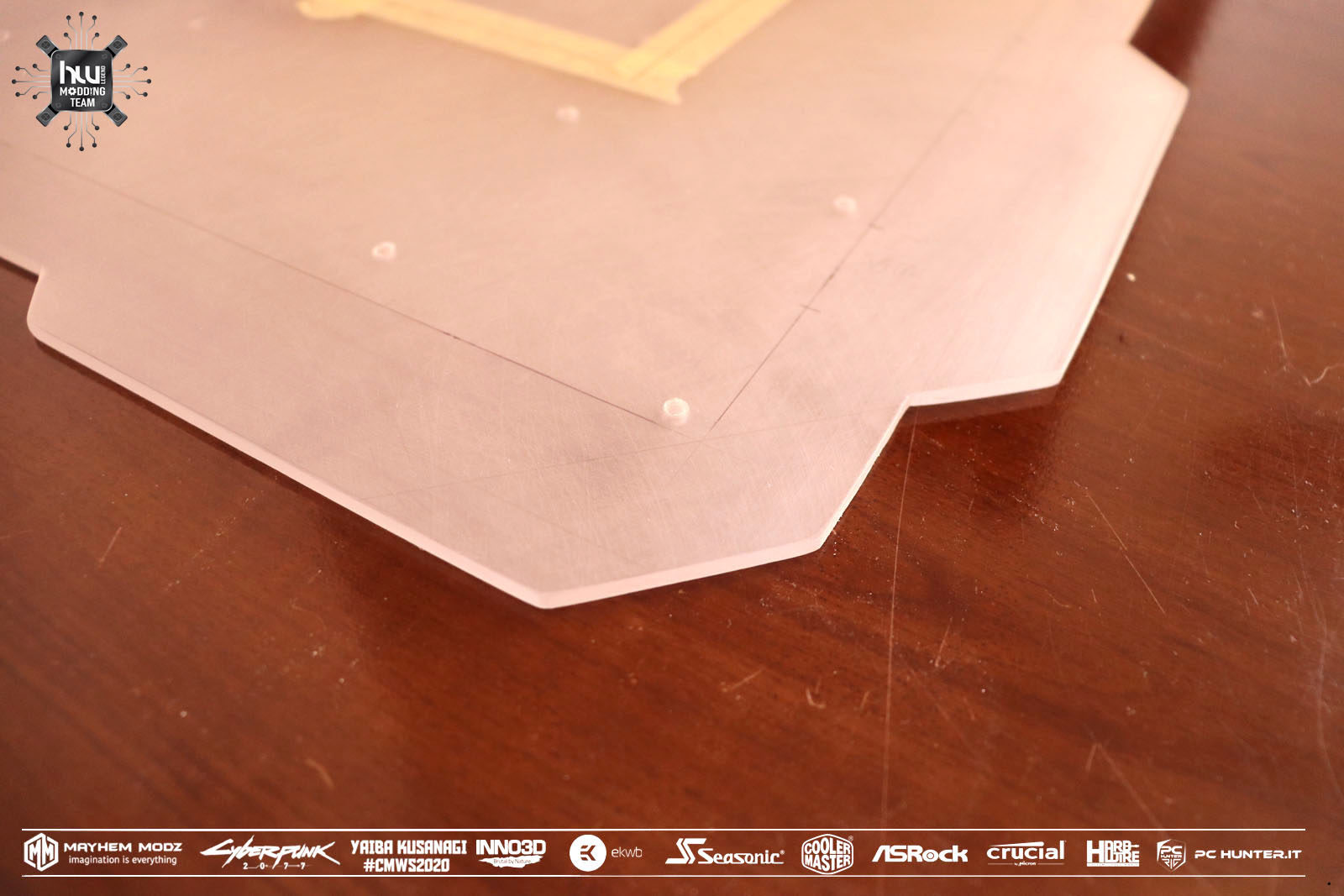

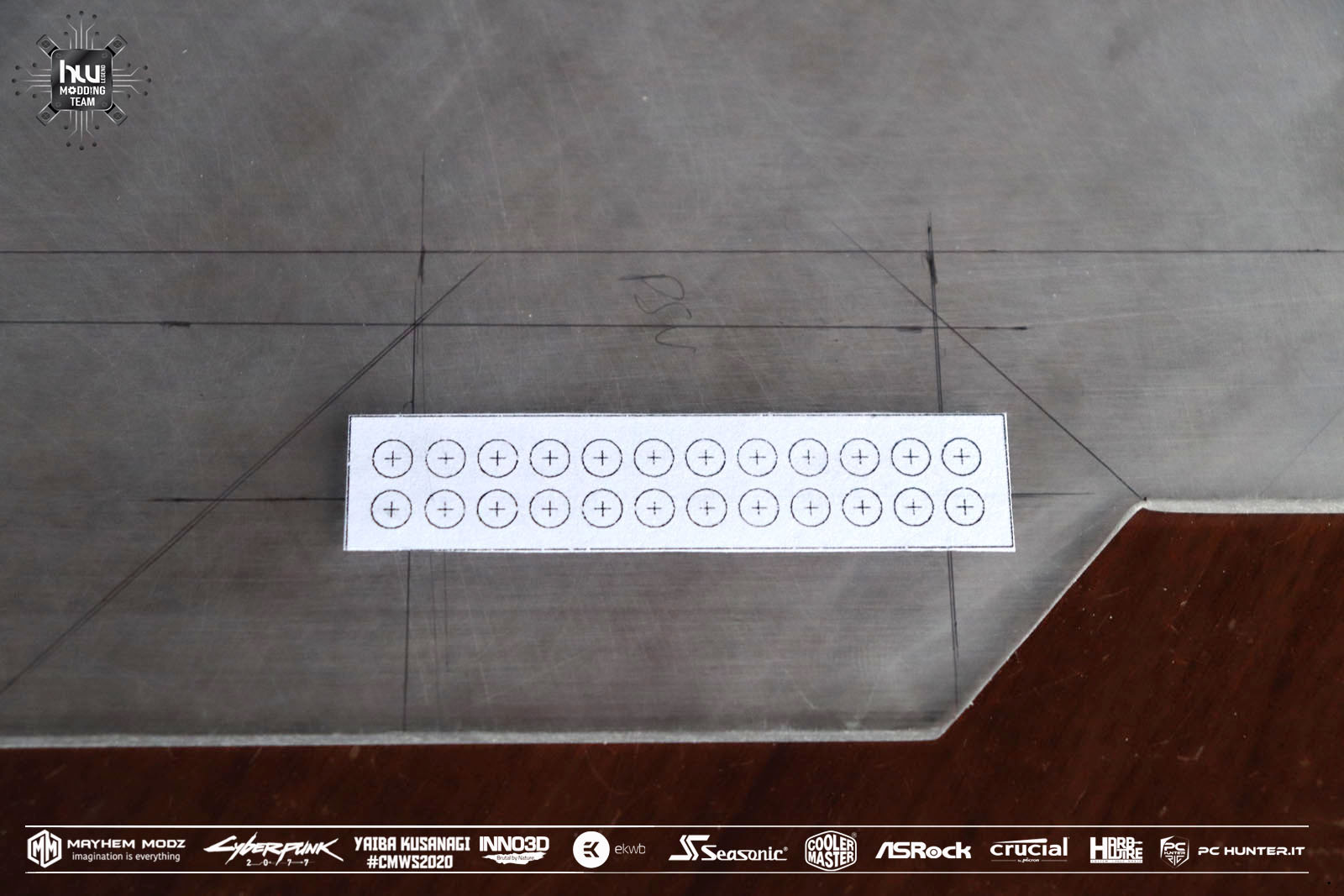

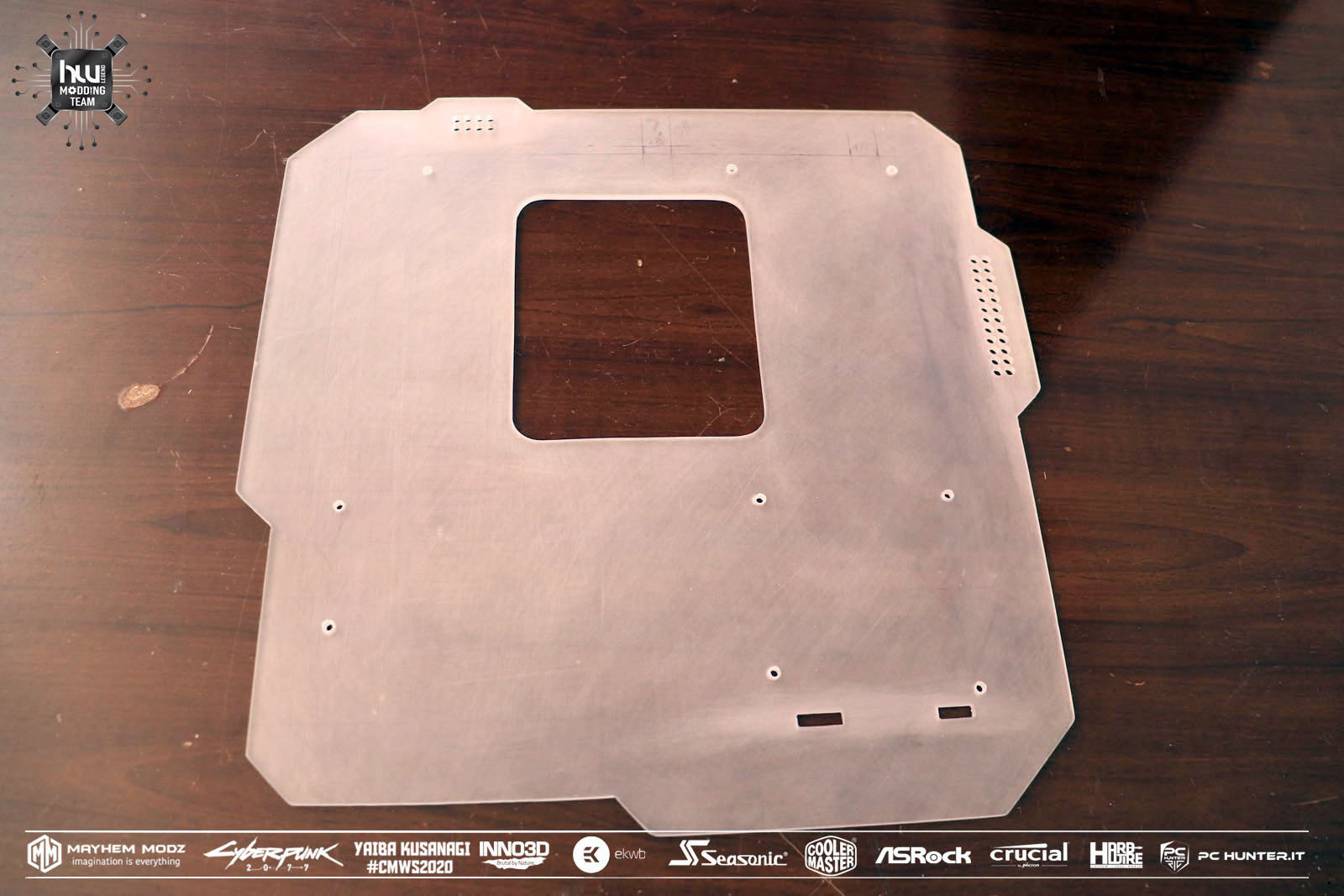

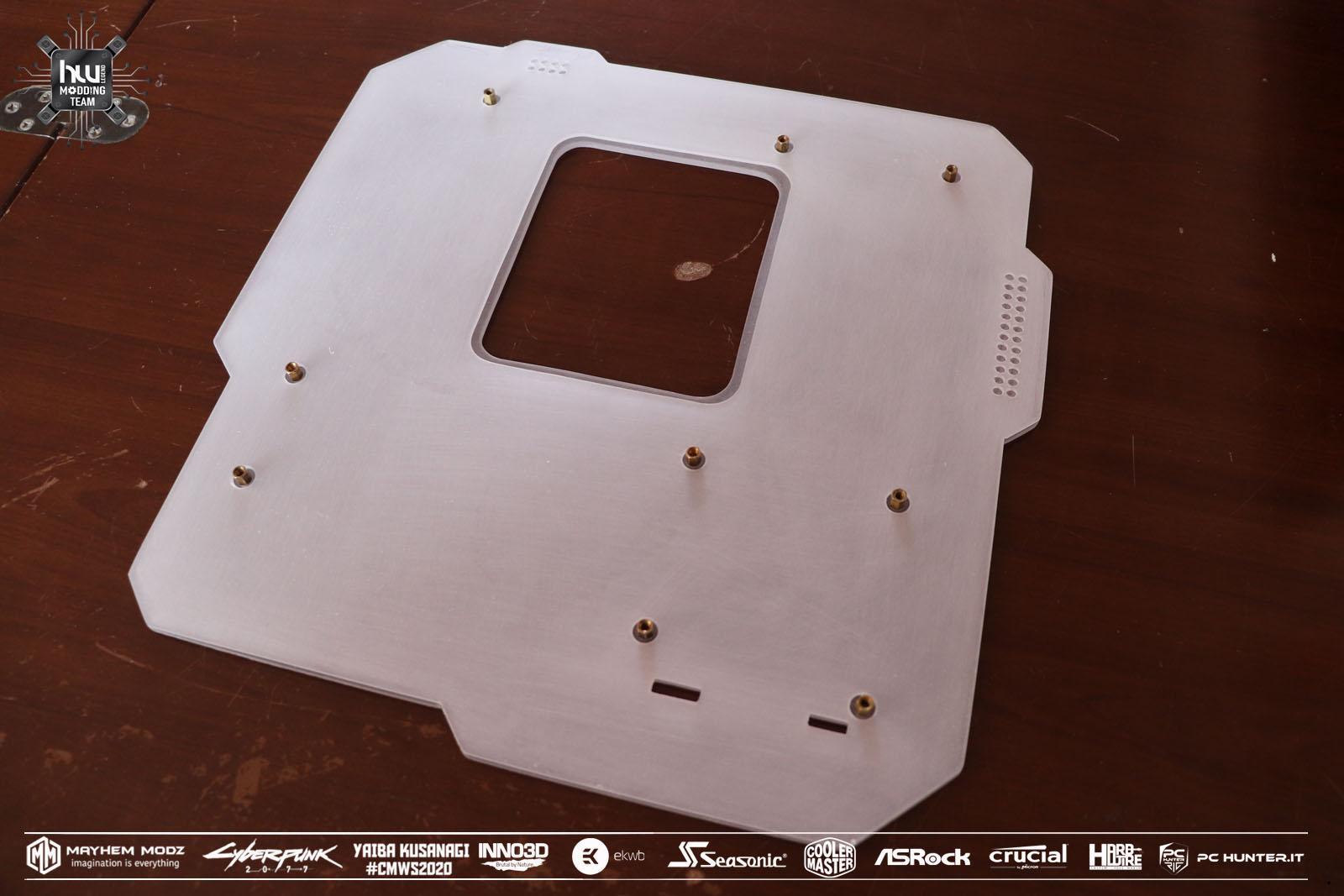

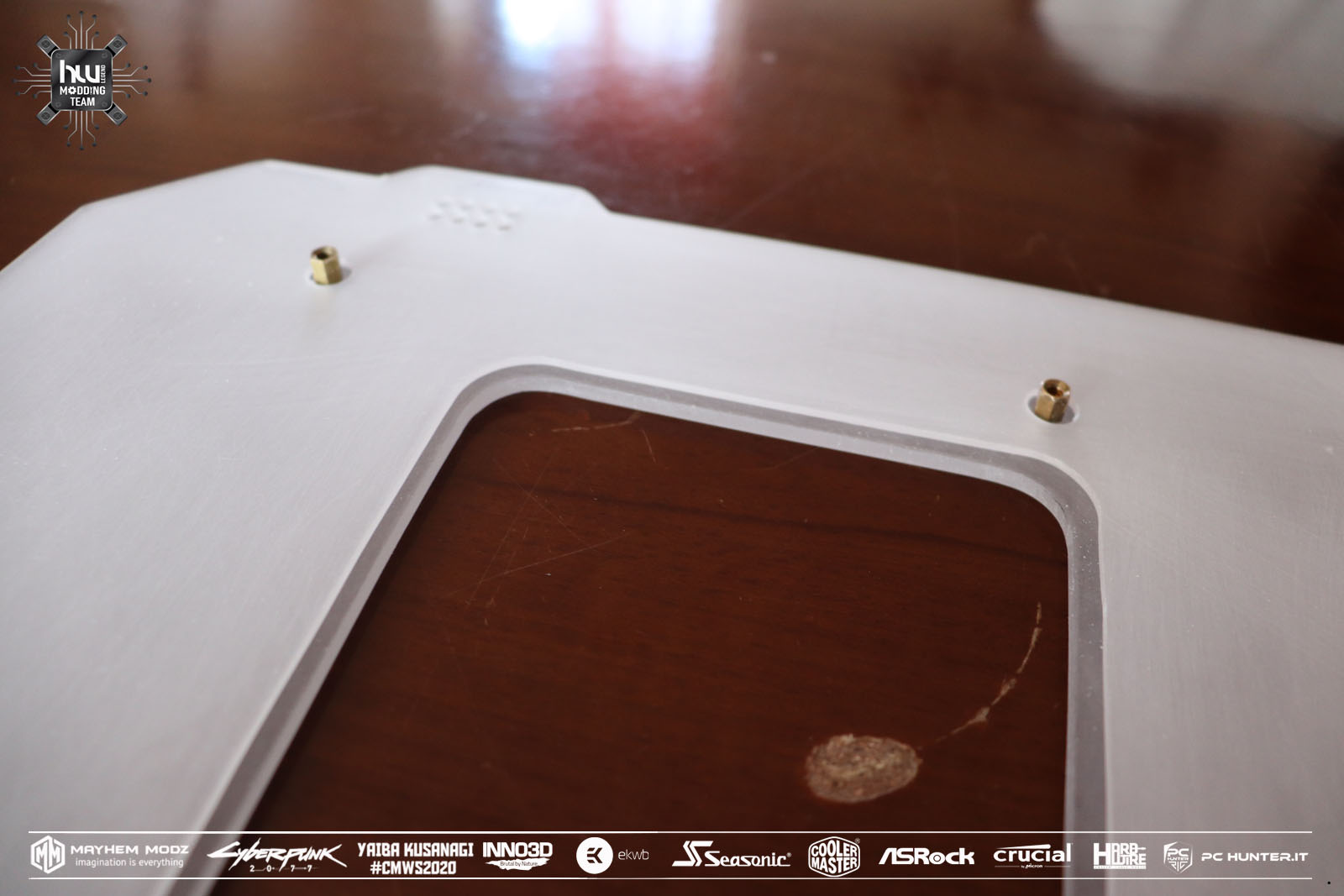

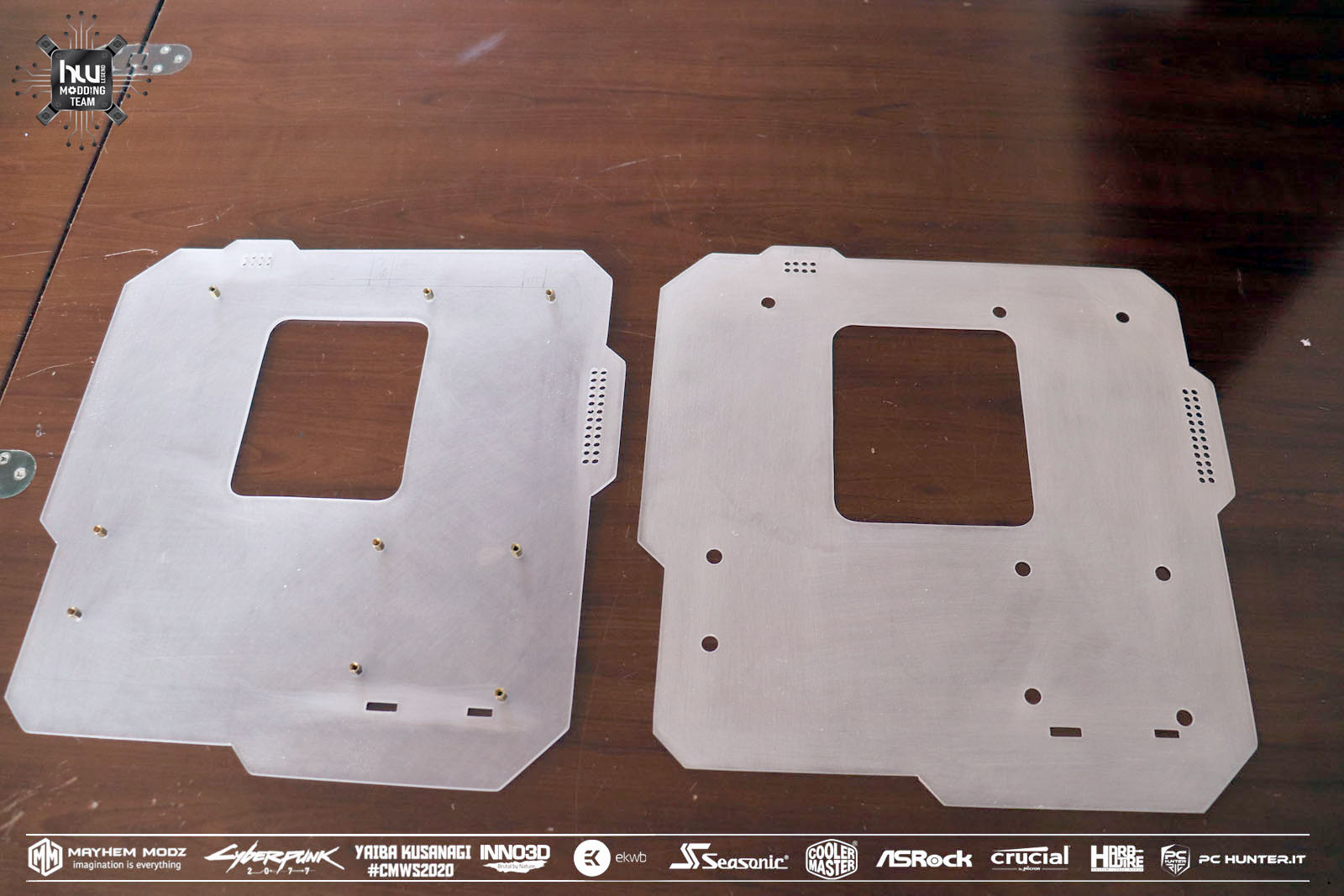

next mod coming soon I could not miss this new project another adventure begins.

thanks to my sponsors

ASROCK, INNO3D, CRUCIAL, SEASONIC, EKWB, HARDWIRE, COOLERMASTER, PC HUNTER

configuration

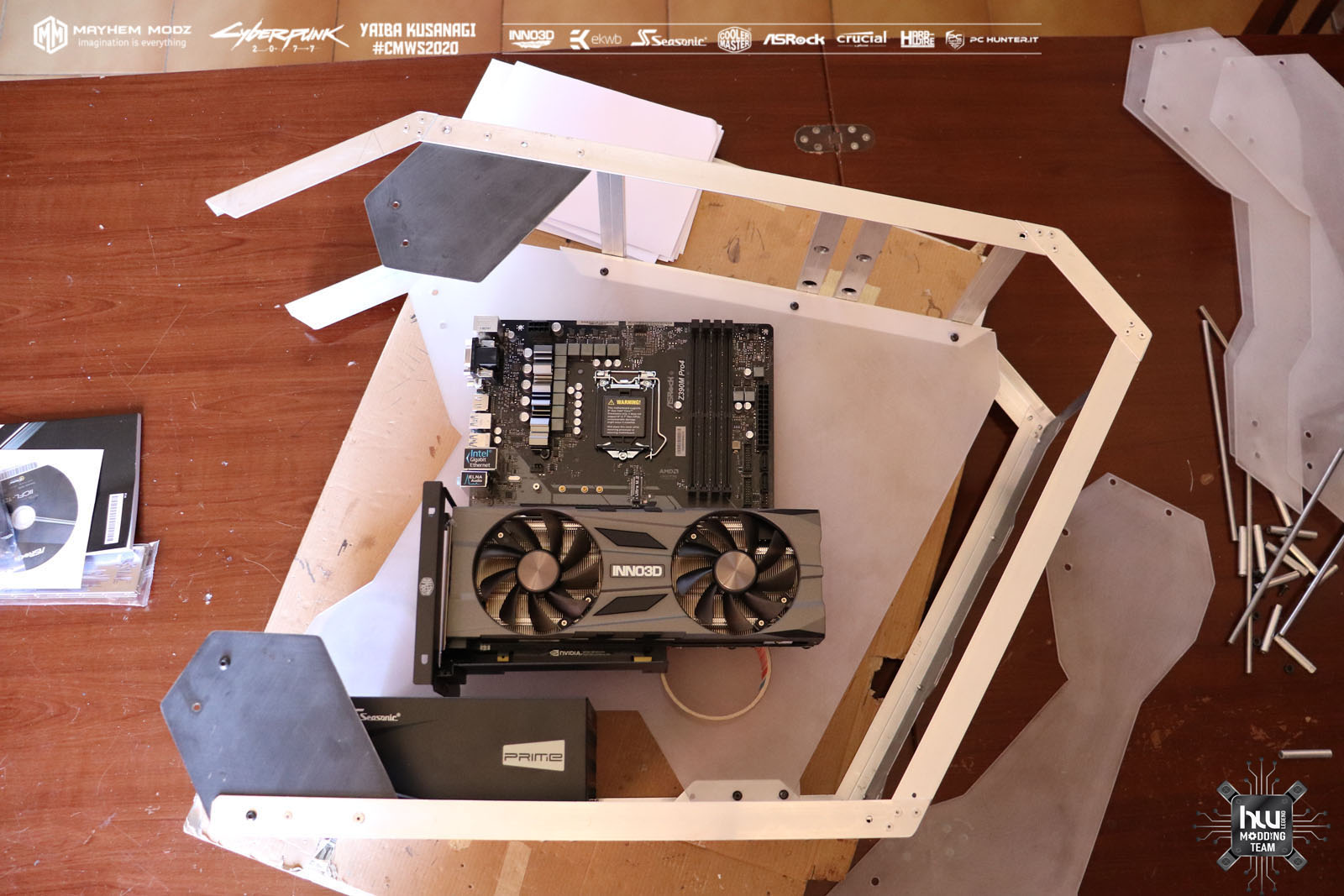

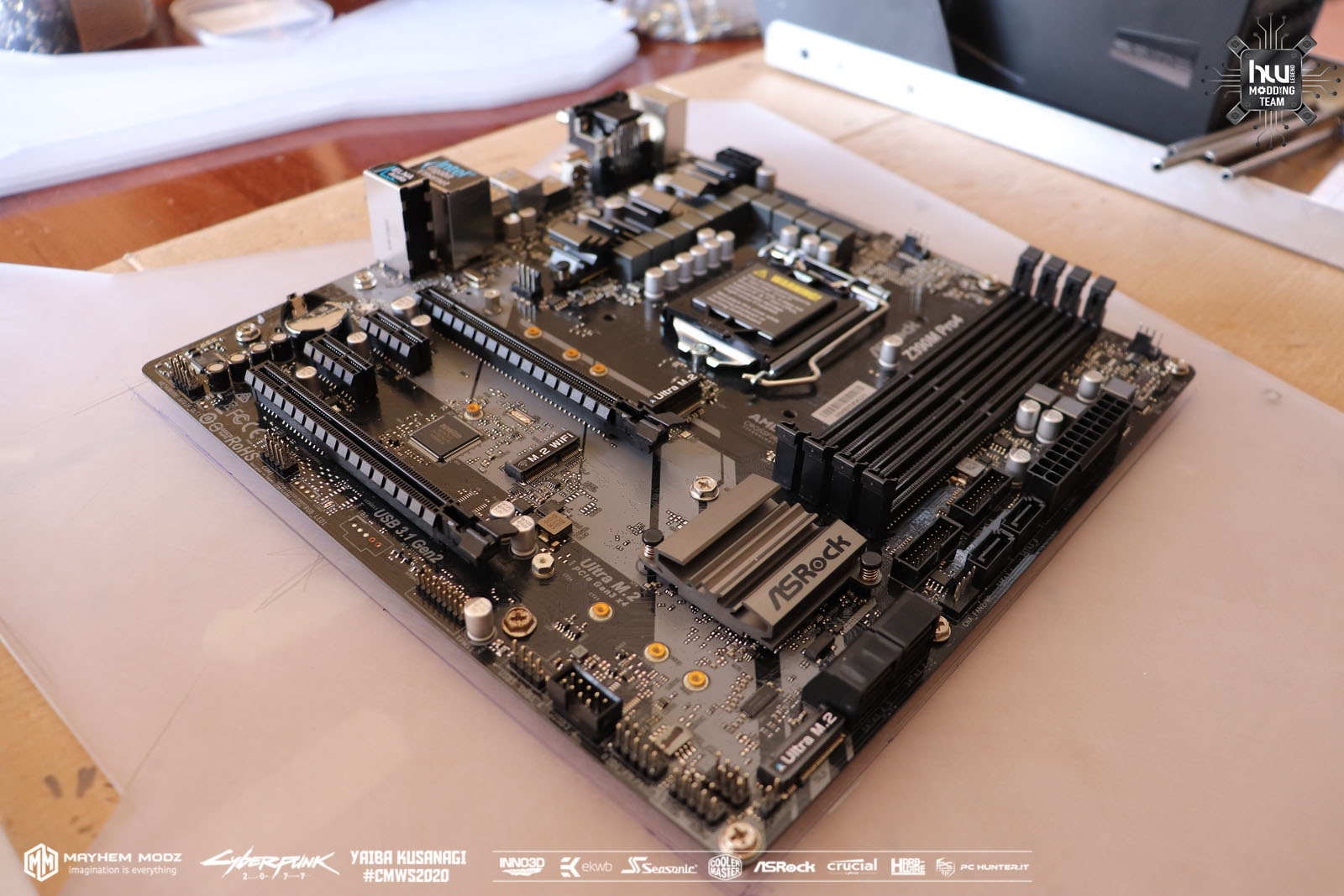

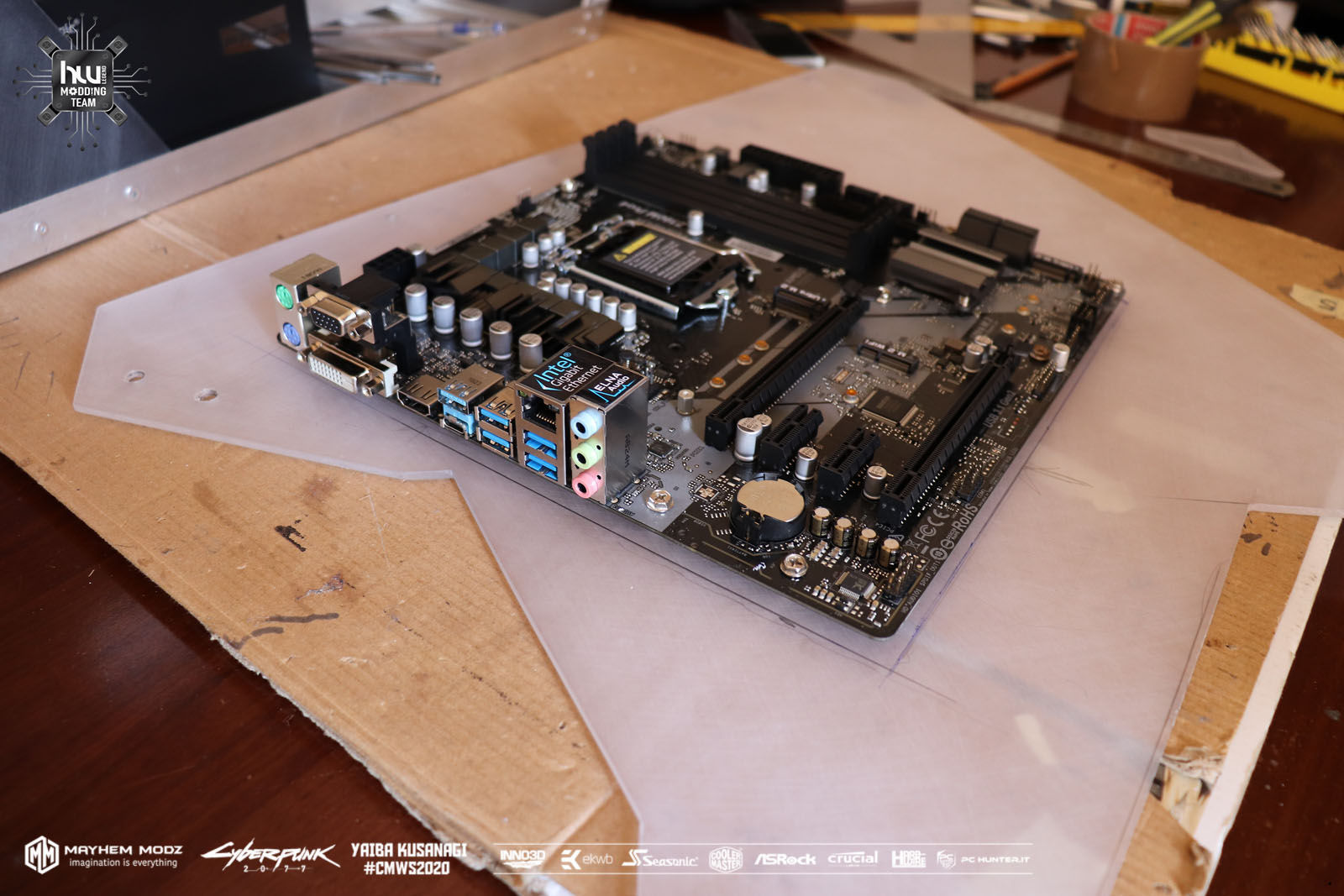

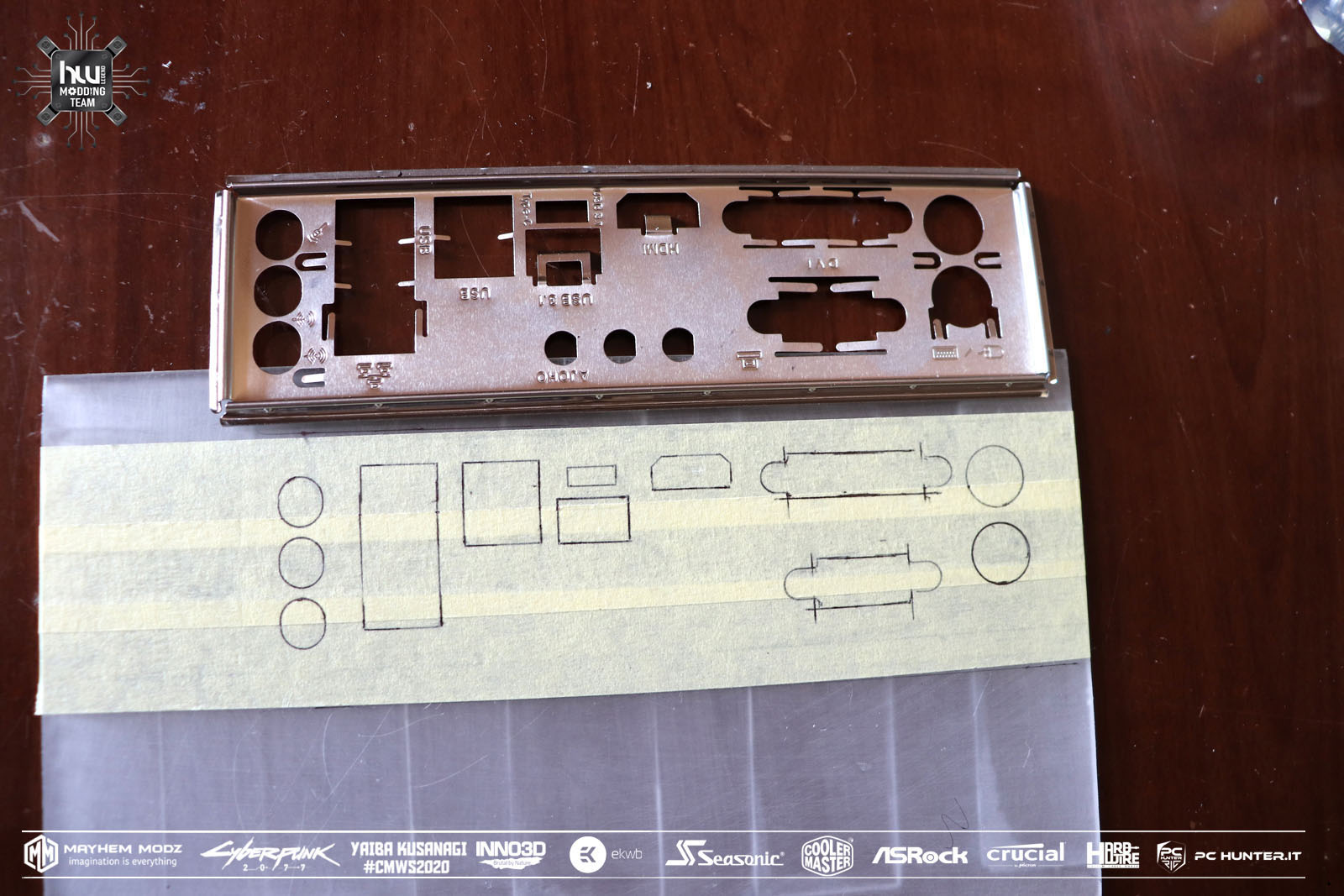

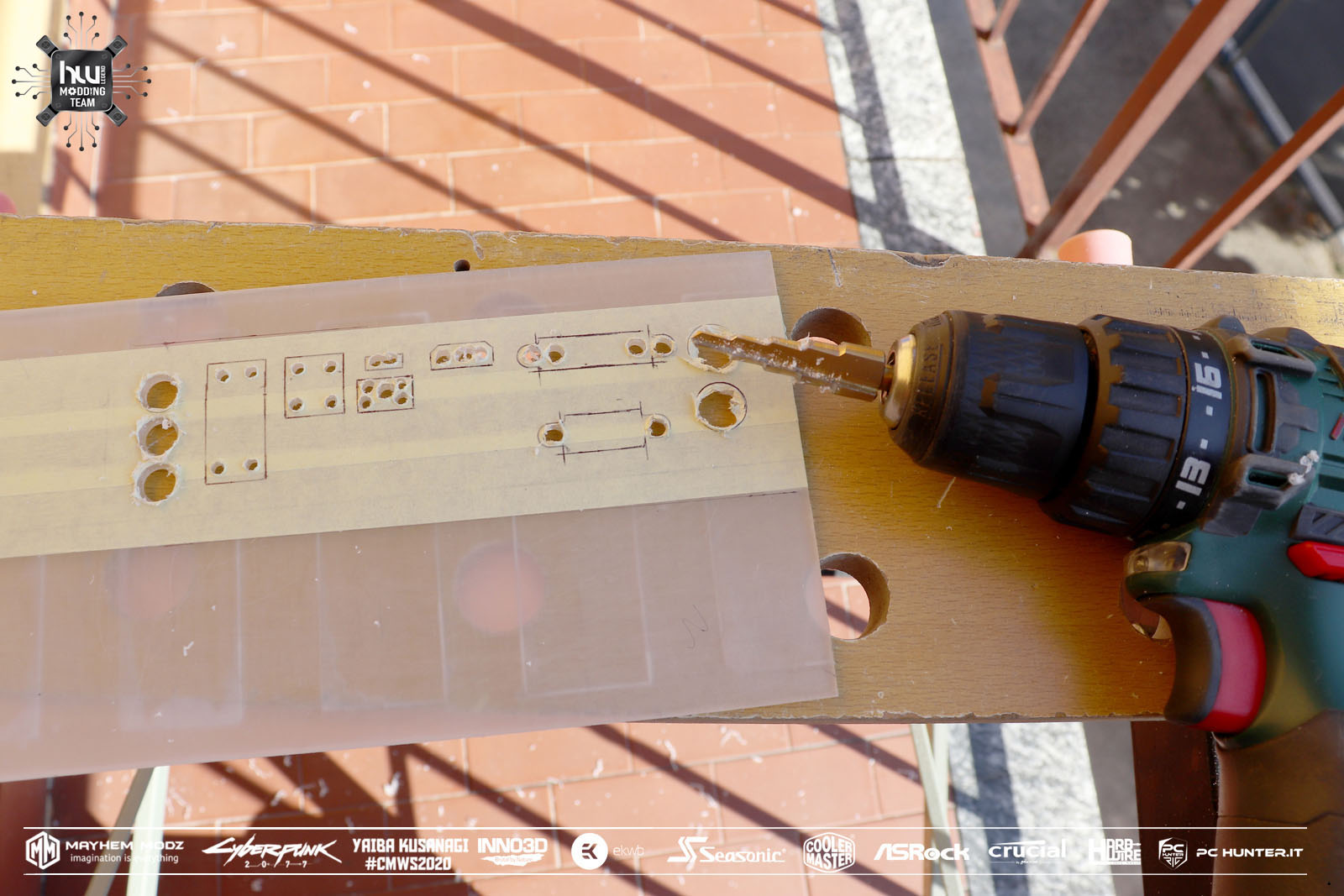

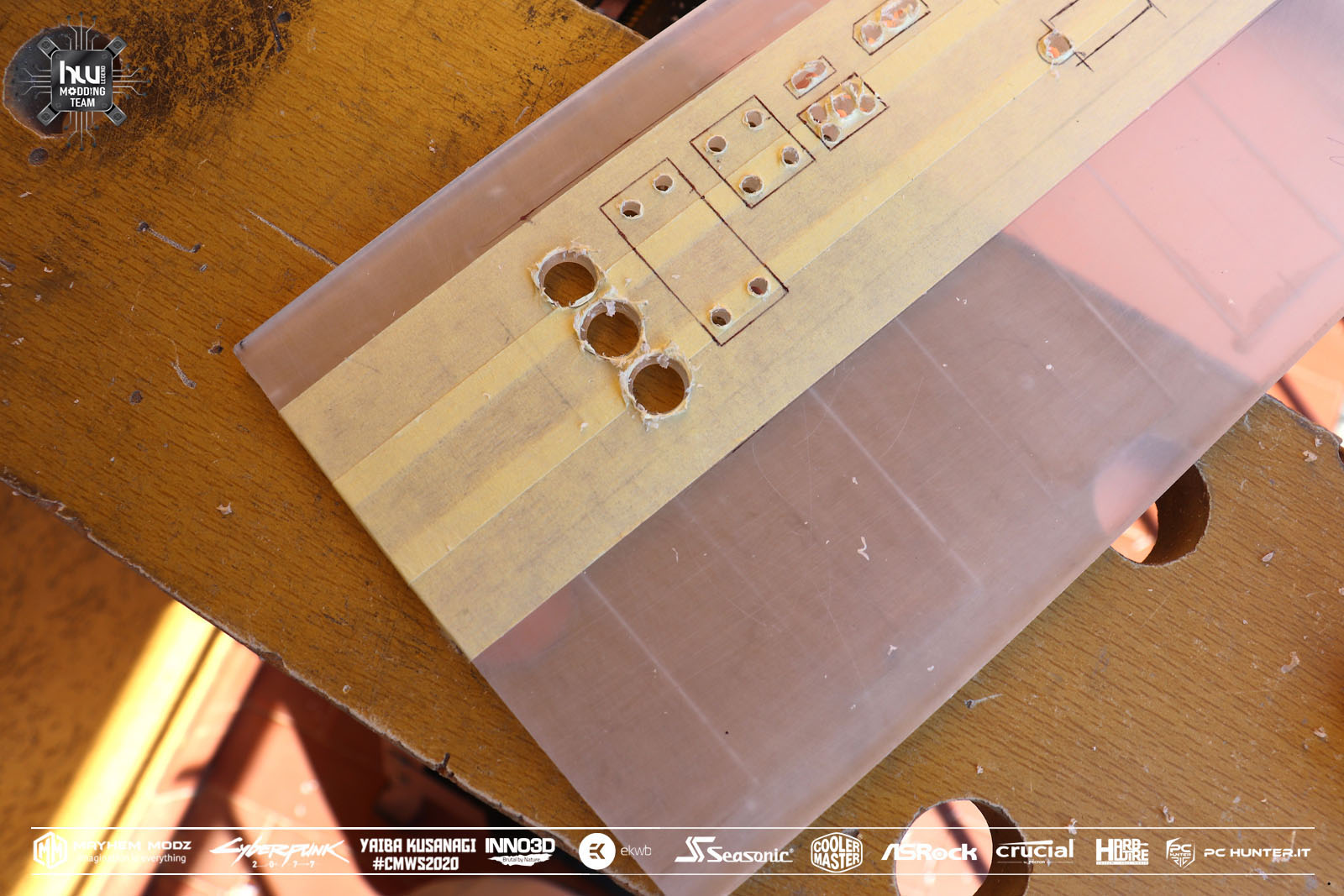

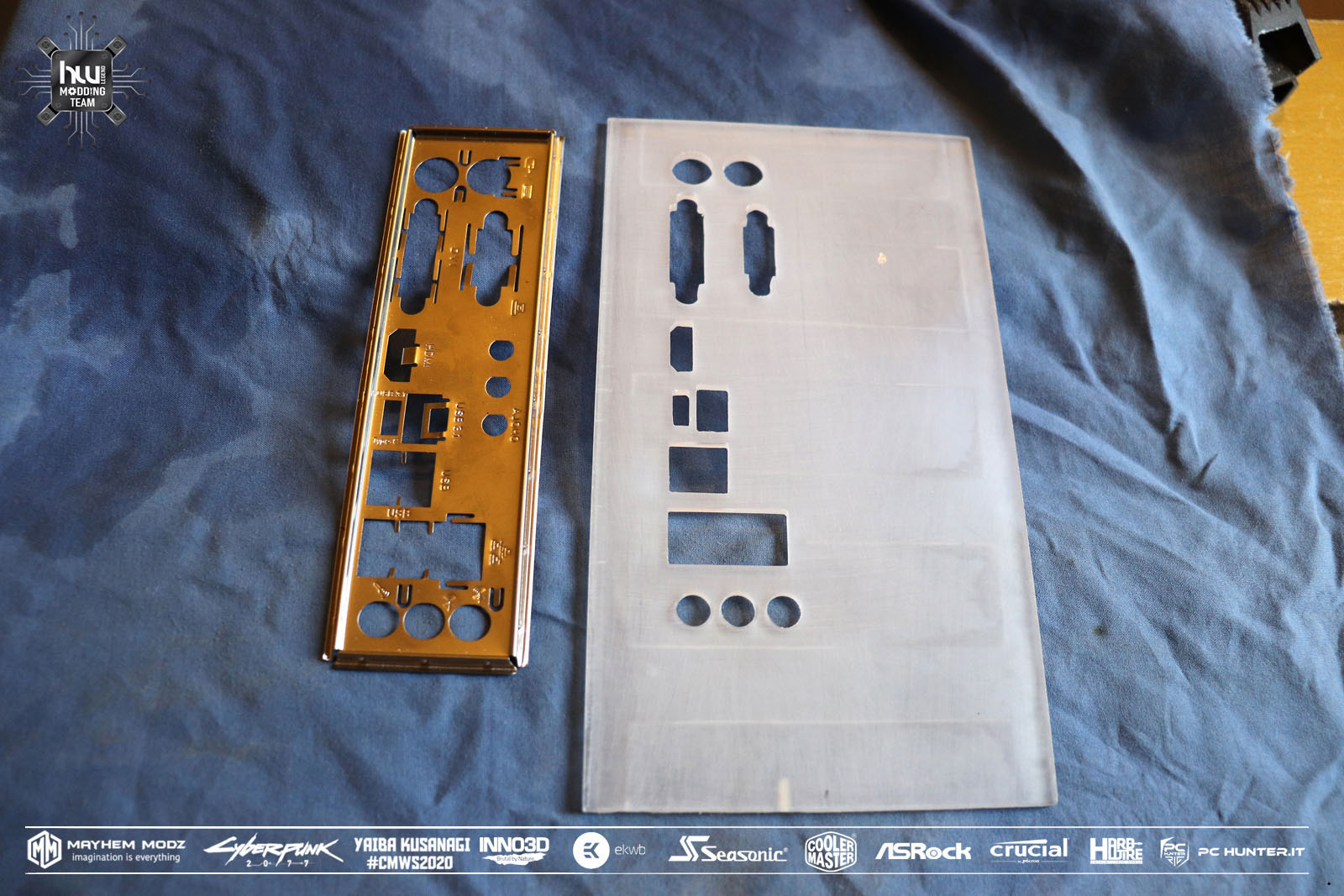

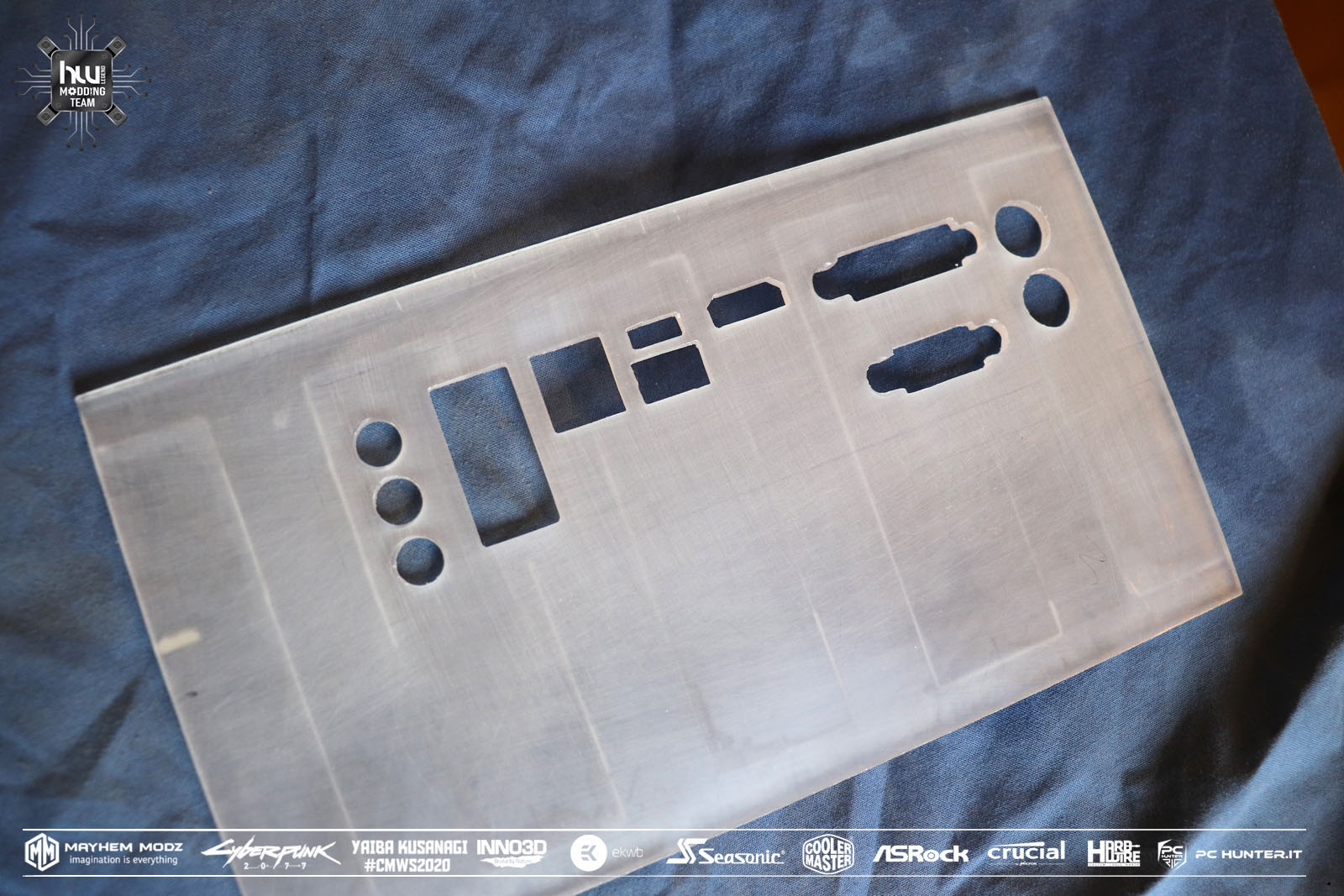

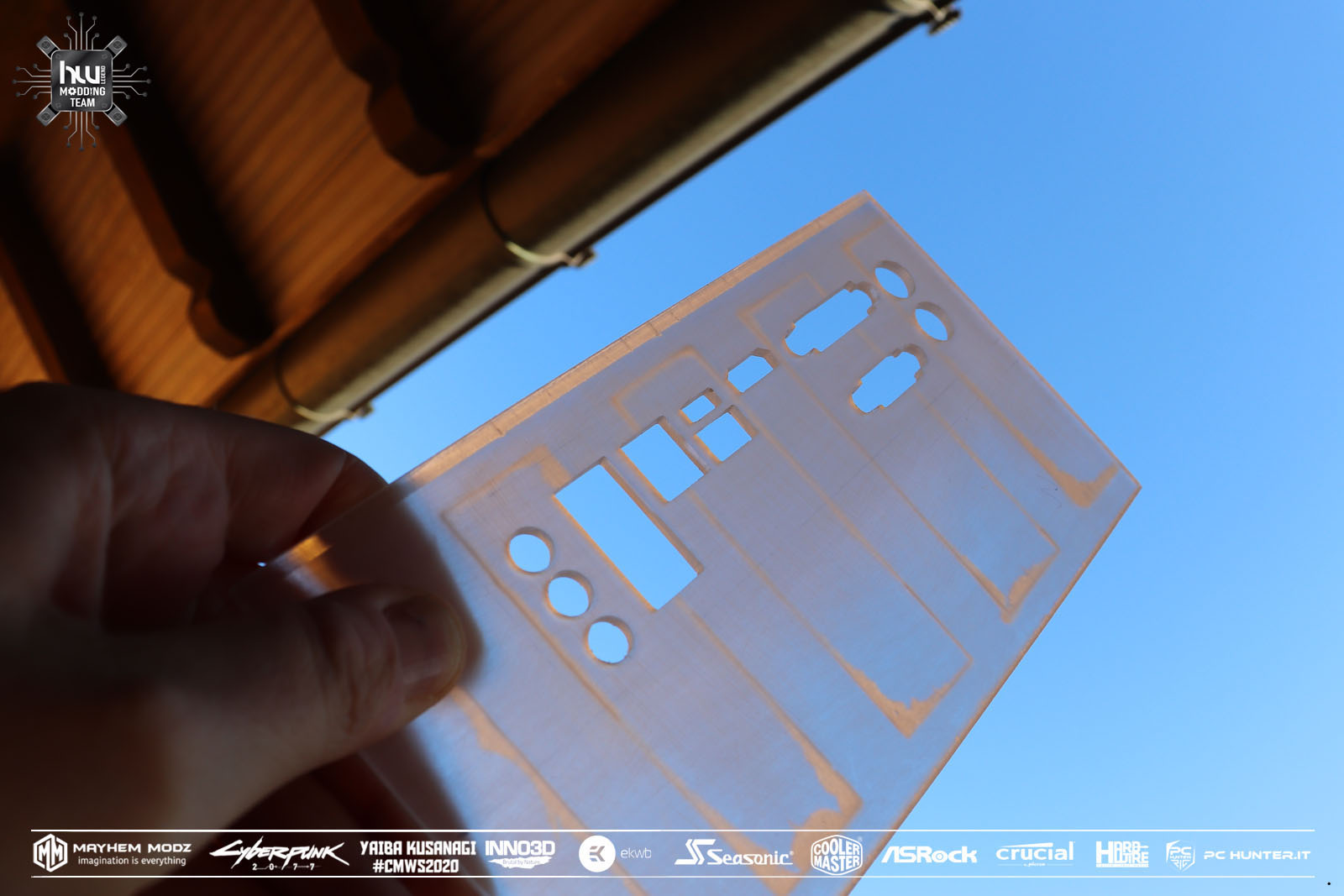

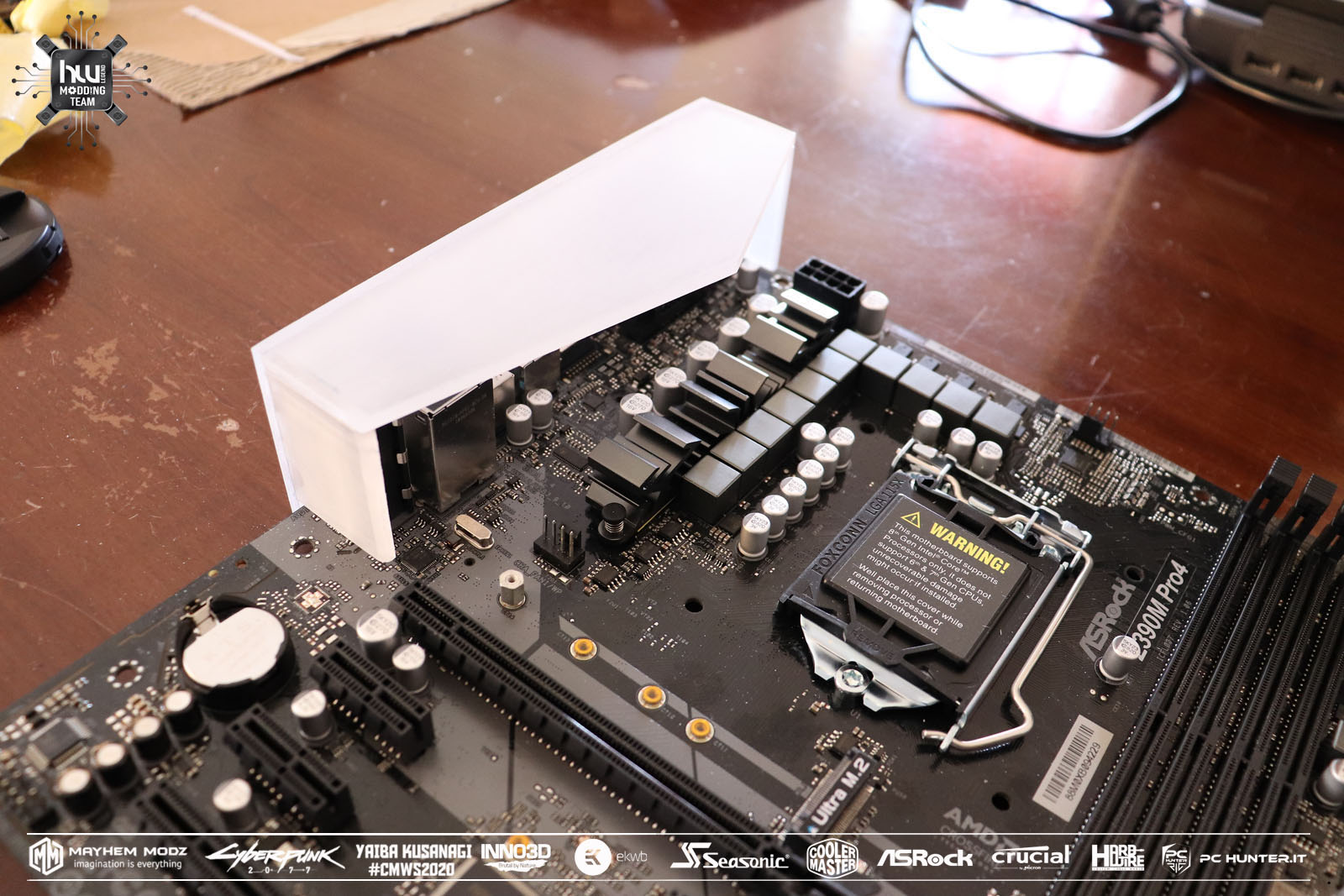

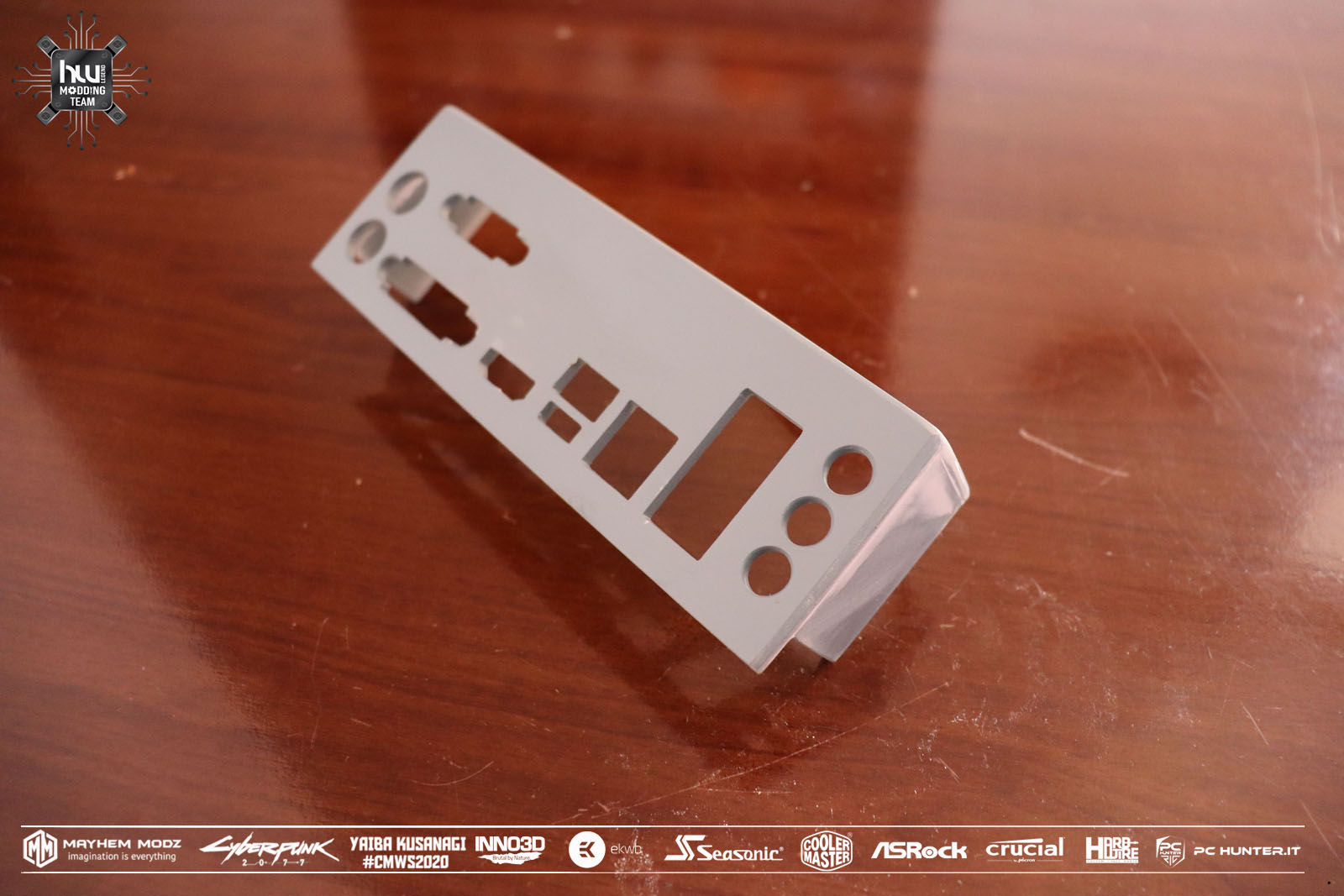

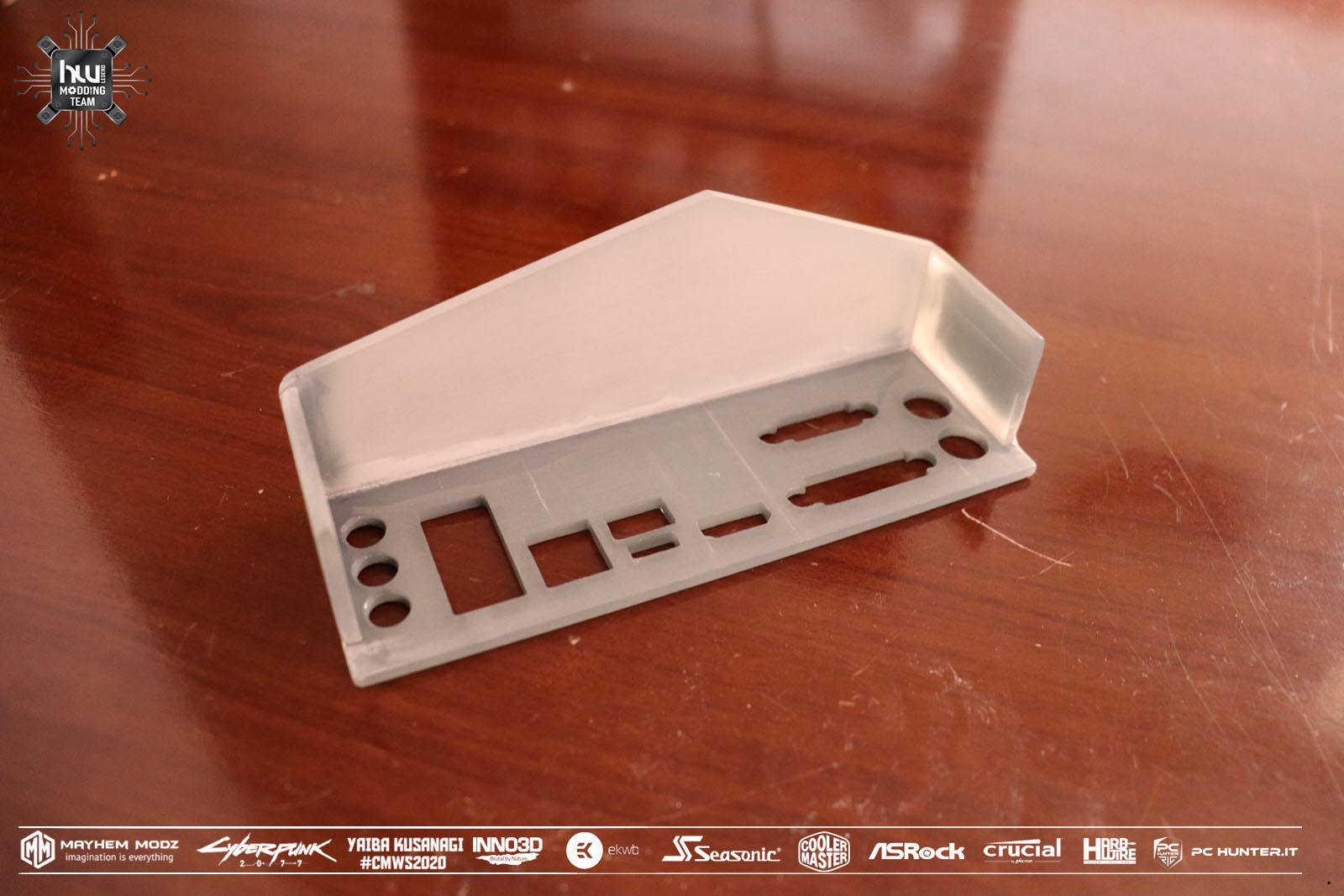

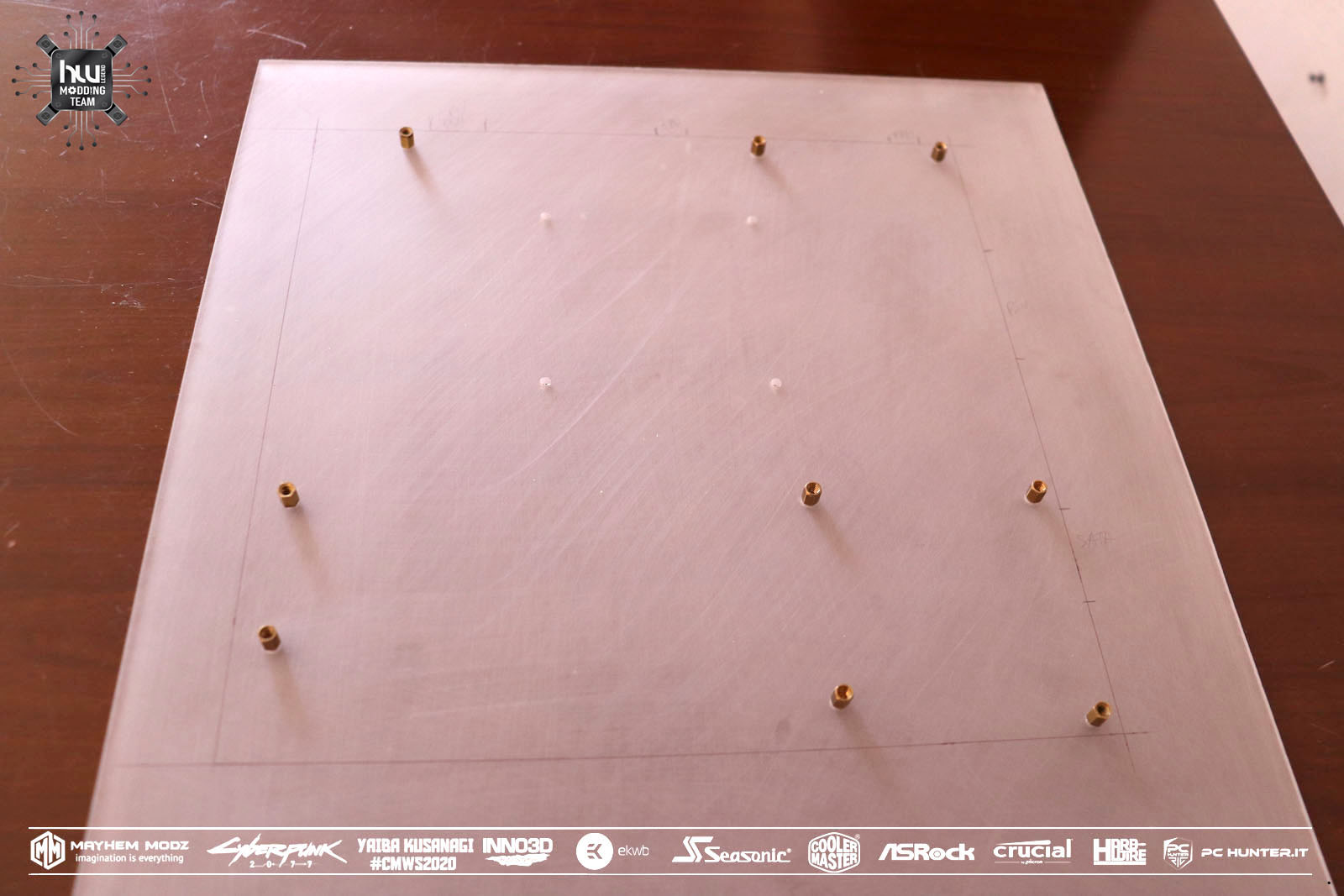

motherboard asrock Z390M PRO 4

cpu intel core I7 9700KF

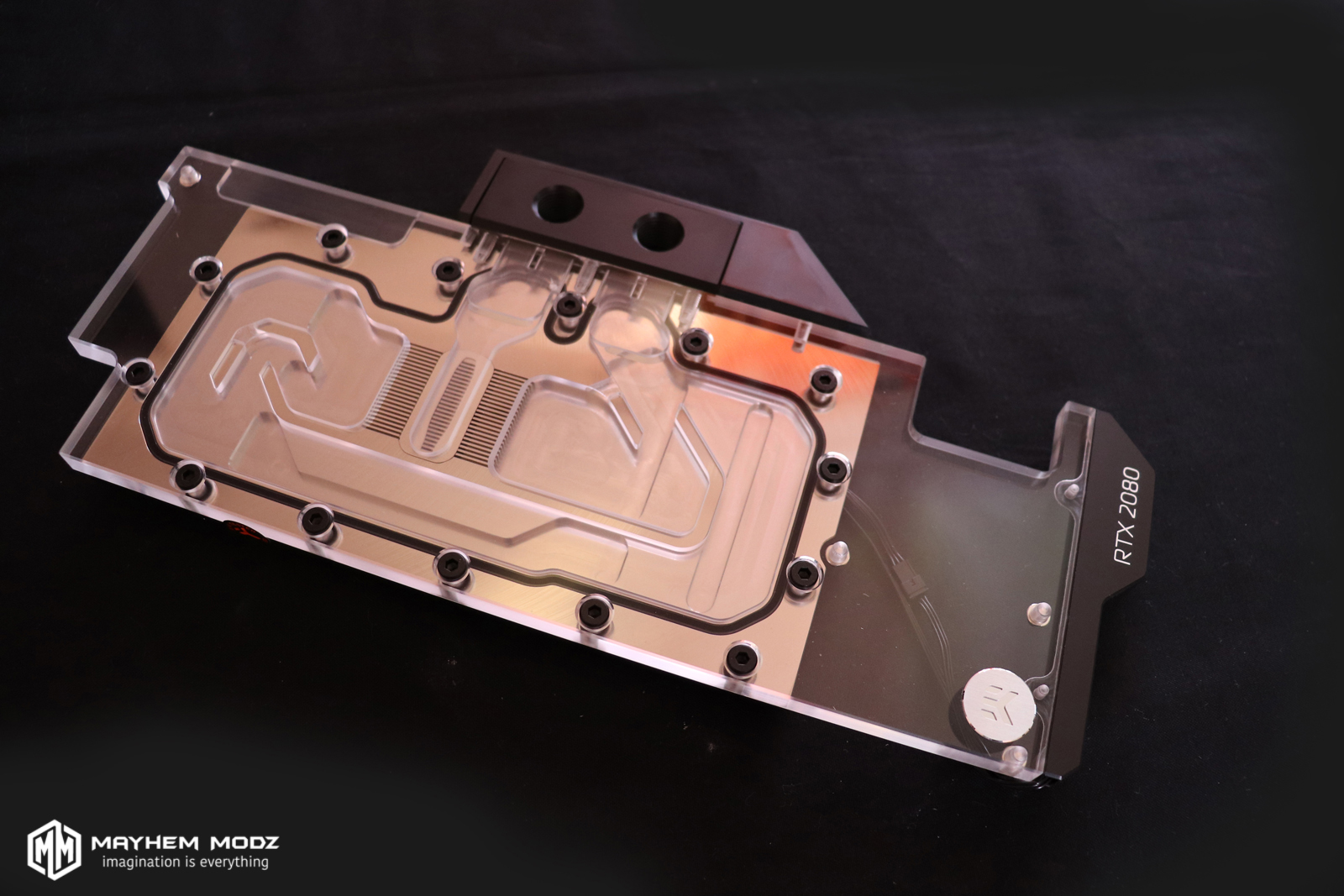

gpu inno3d geforce rtx 2080 super twin x2 oc

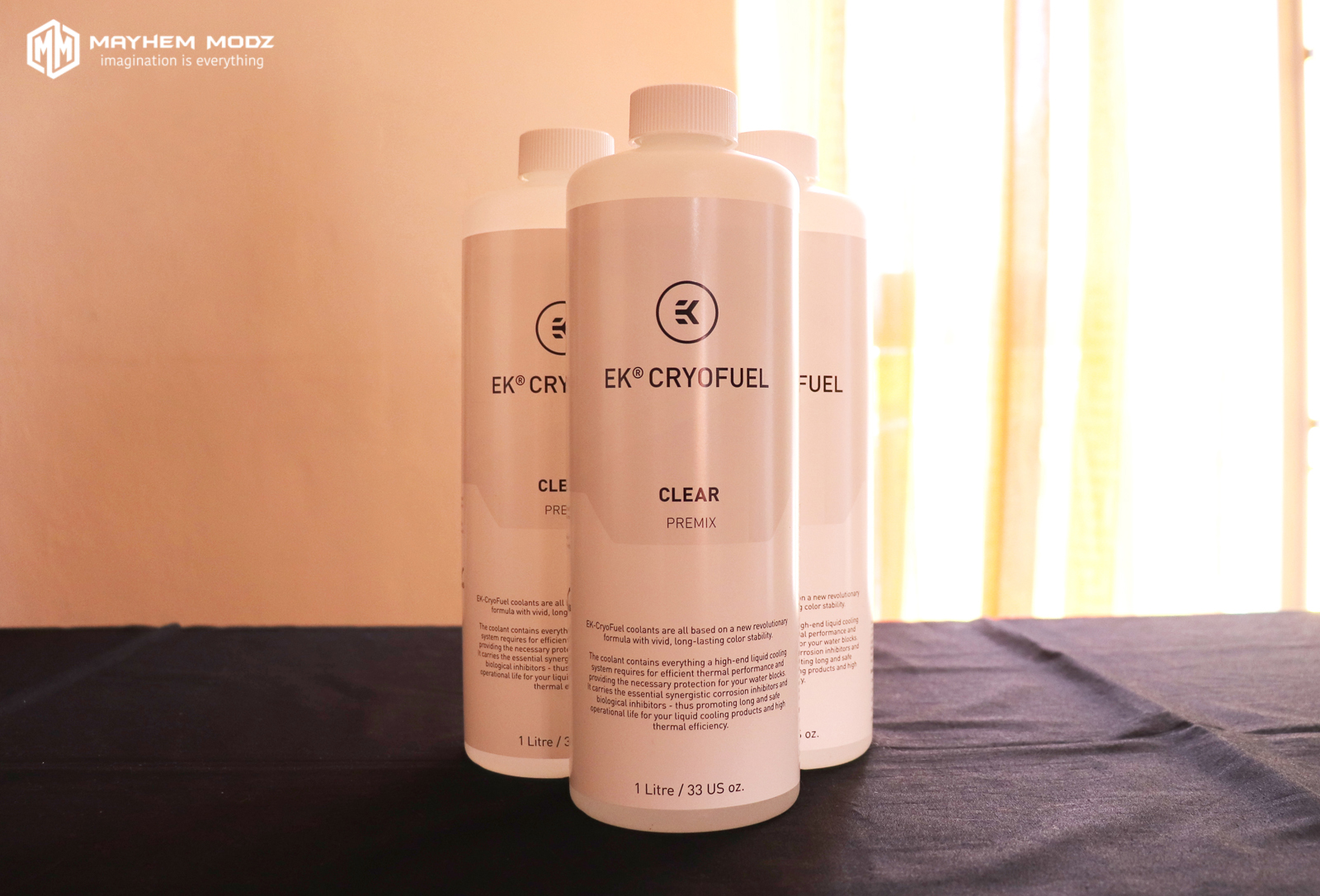

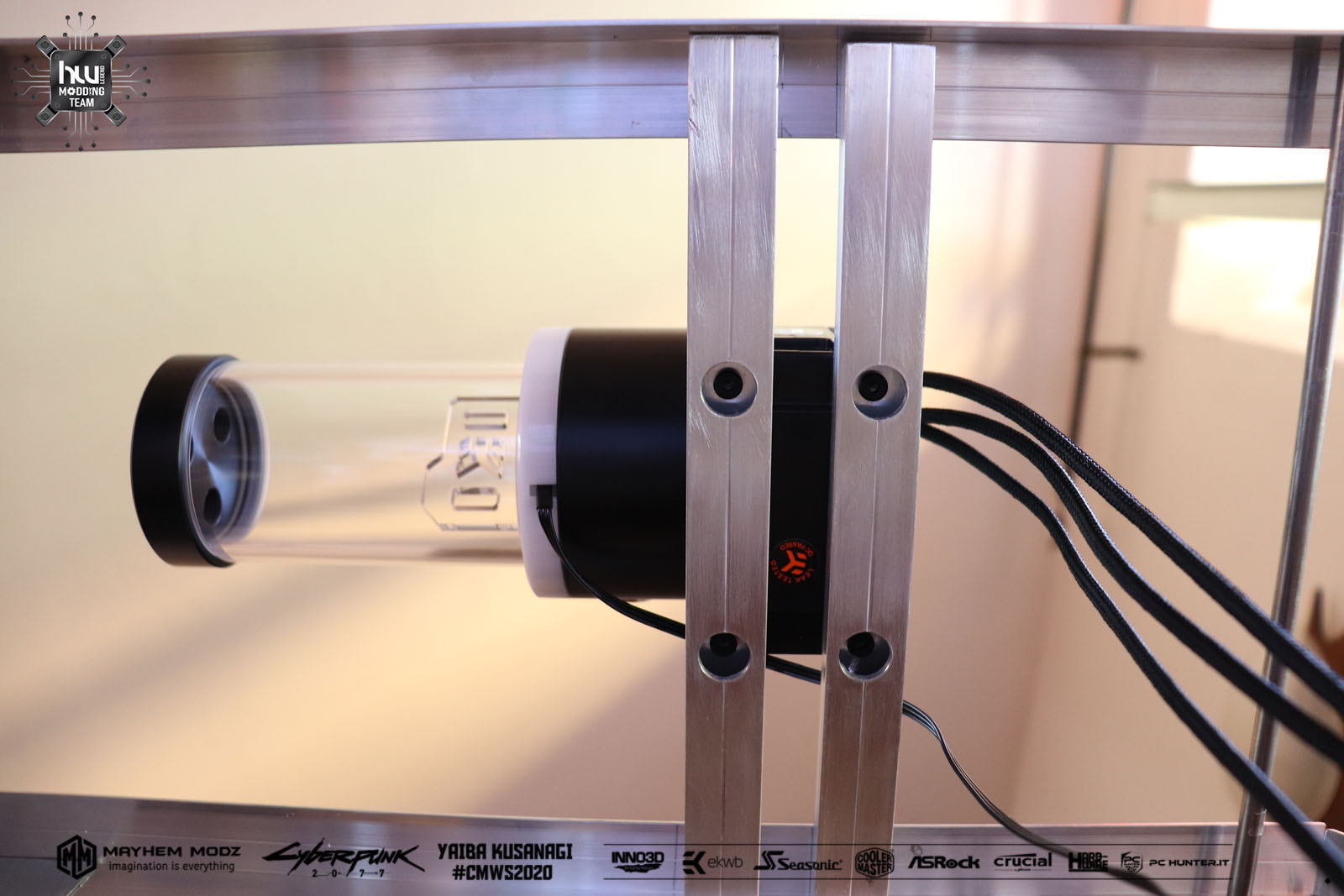

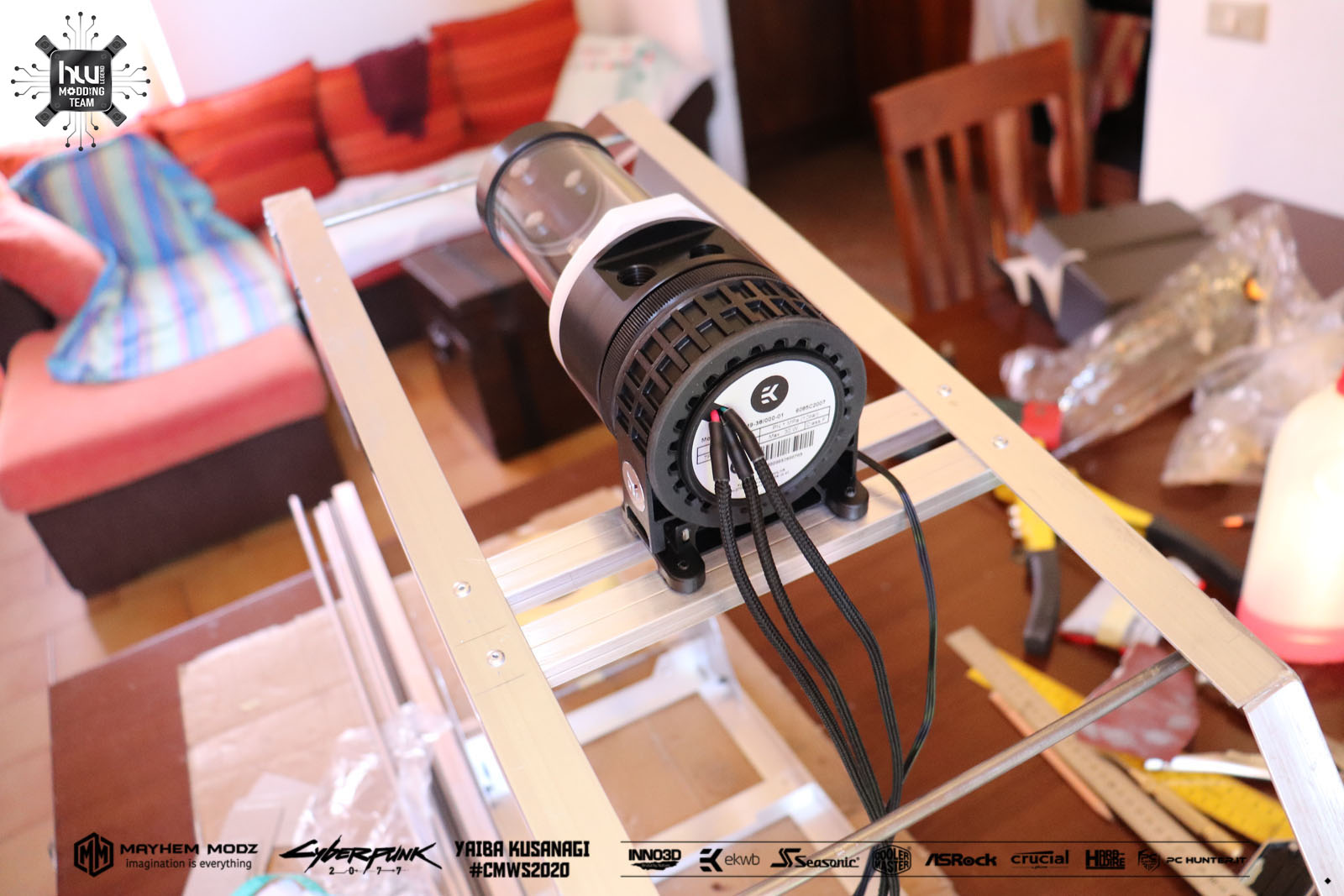

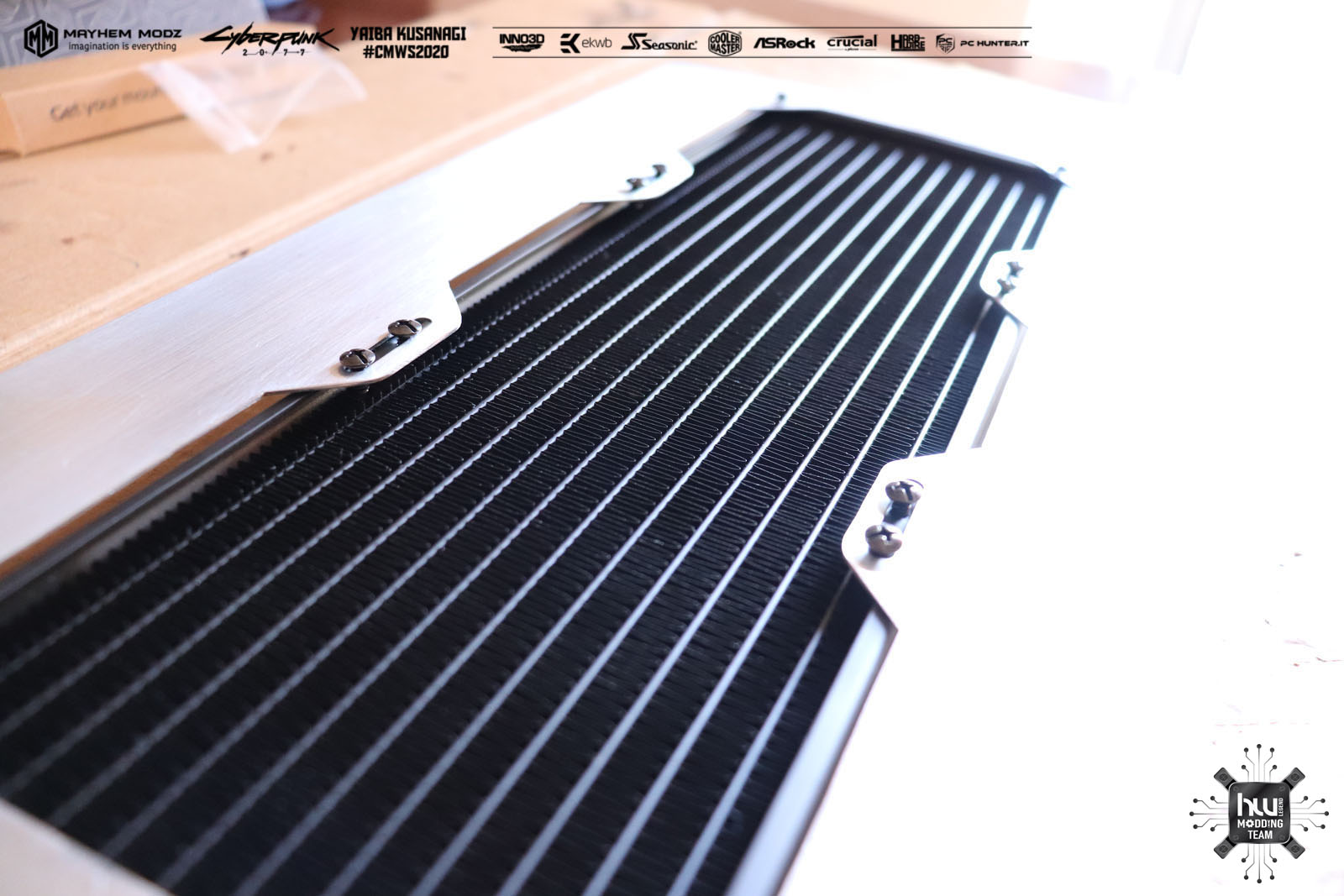

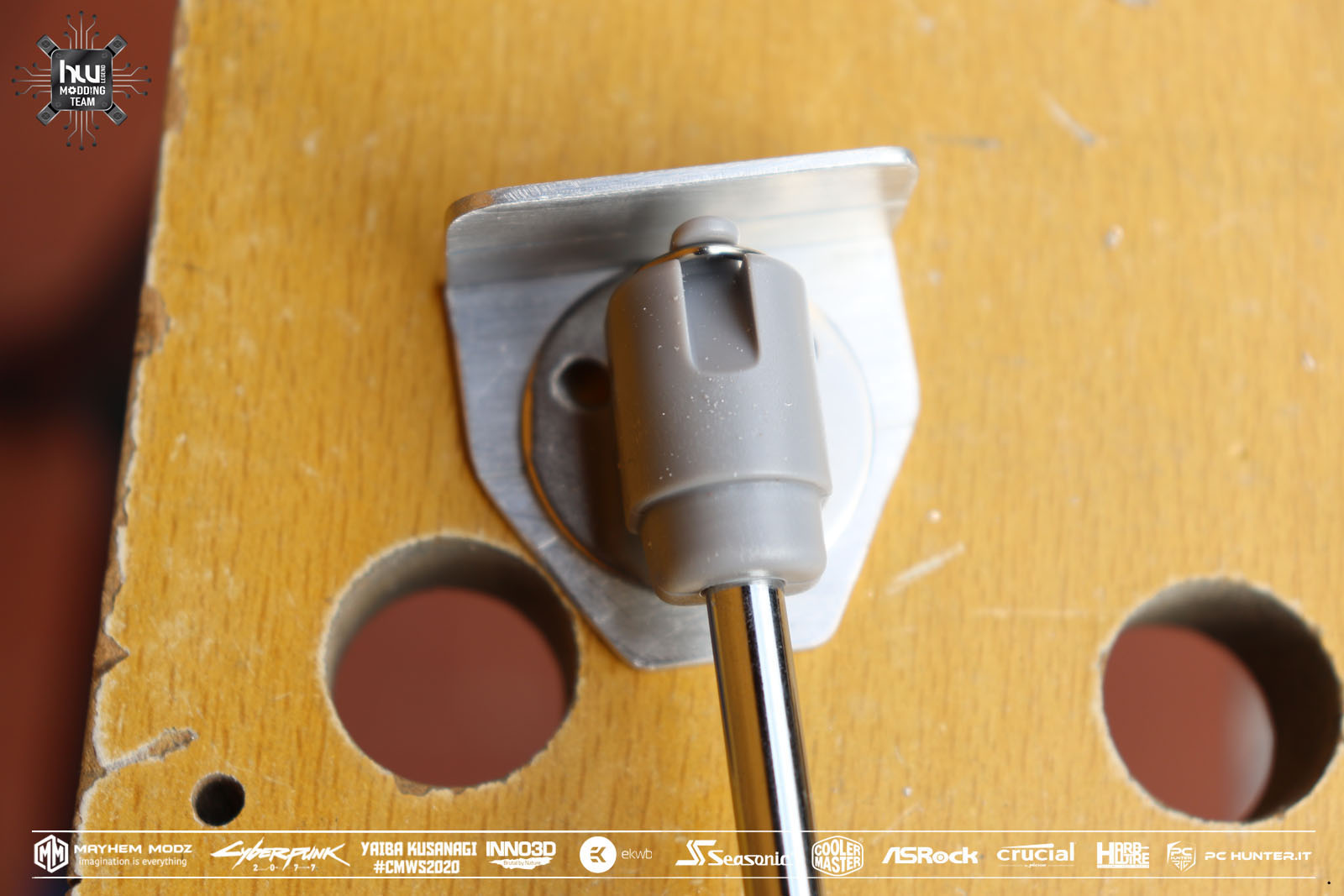

cooling EKWB custom loop

crucial memory ballistix max 32 gb kit

crucial memory ssdmx500 x2

crucial memory M2 1TB P1

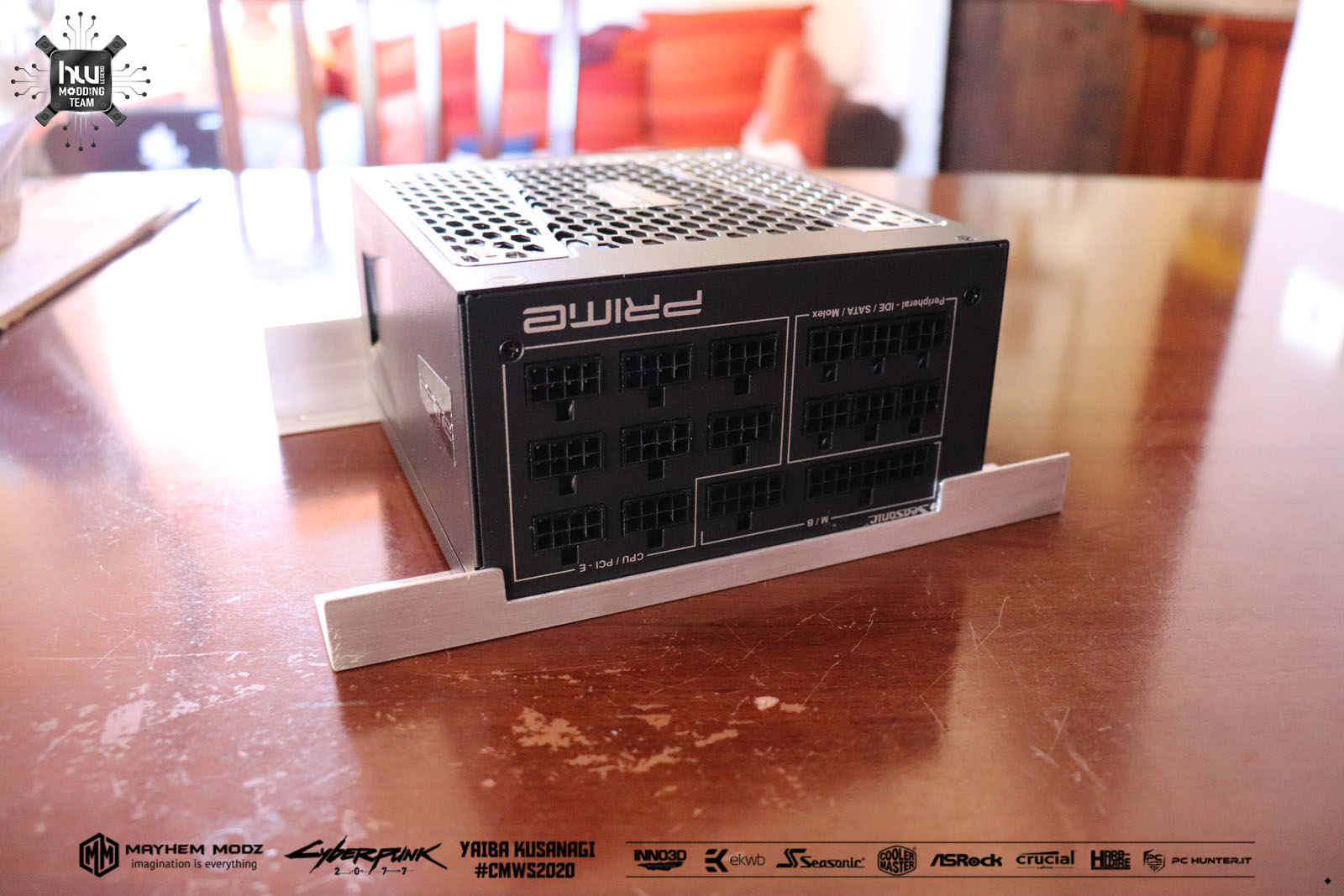

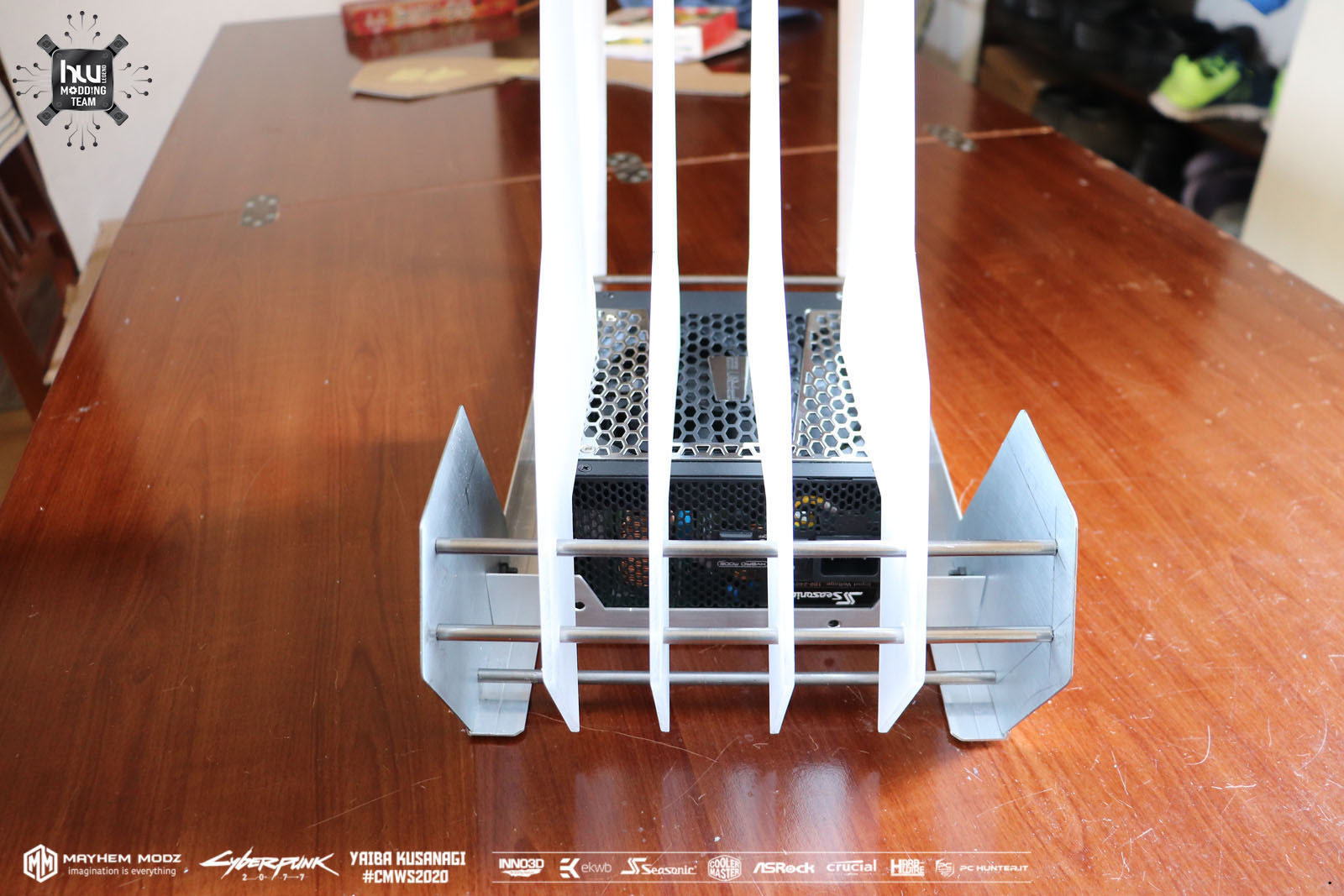

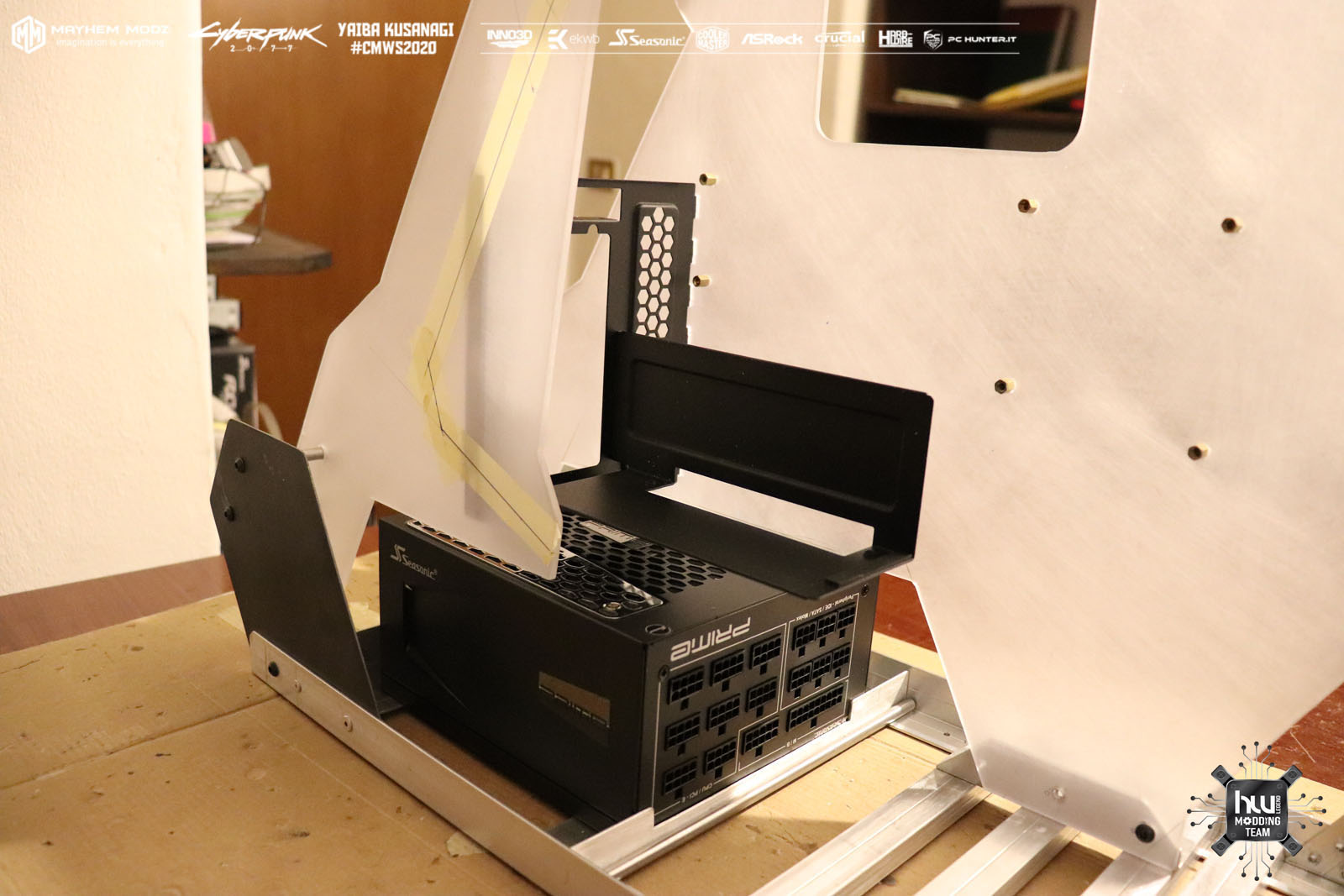

psu seasonic prime PX850W

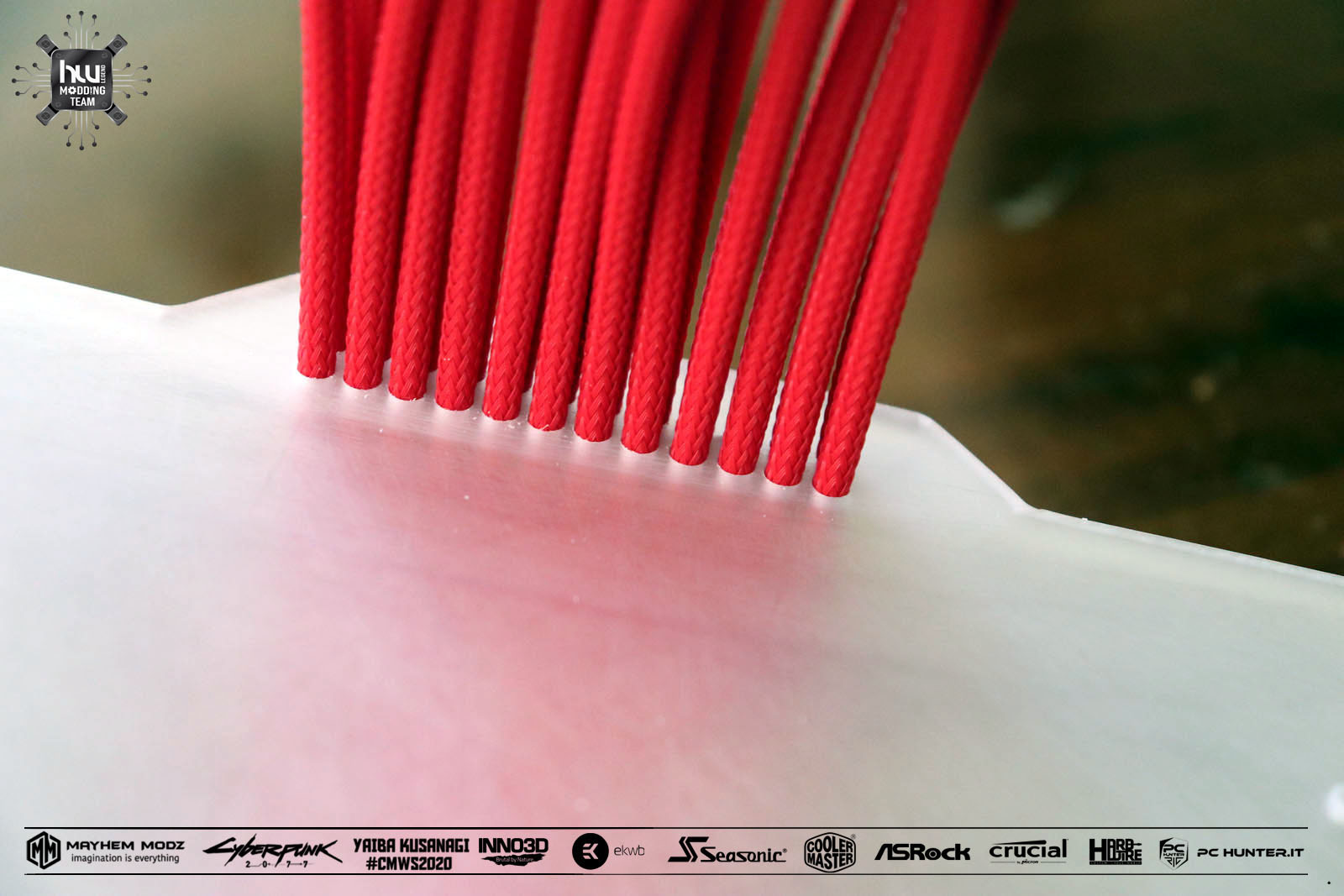

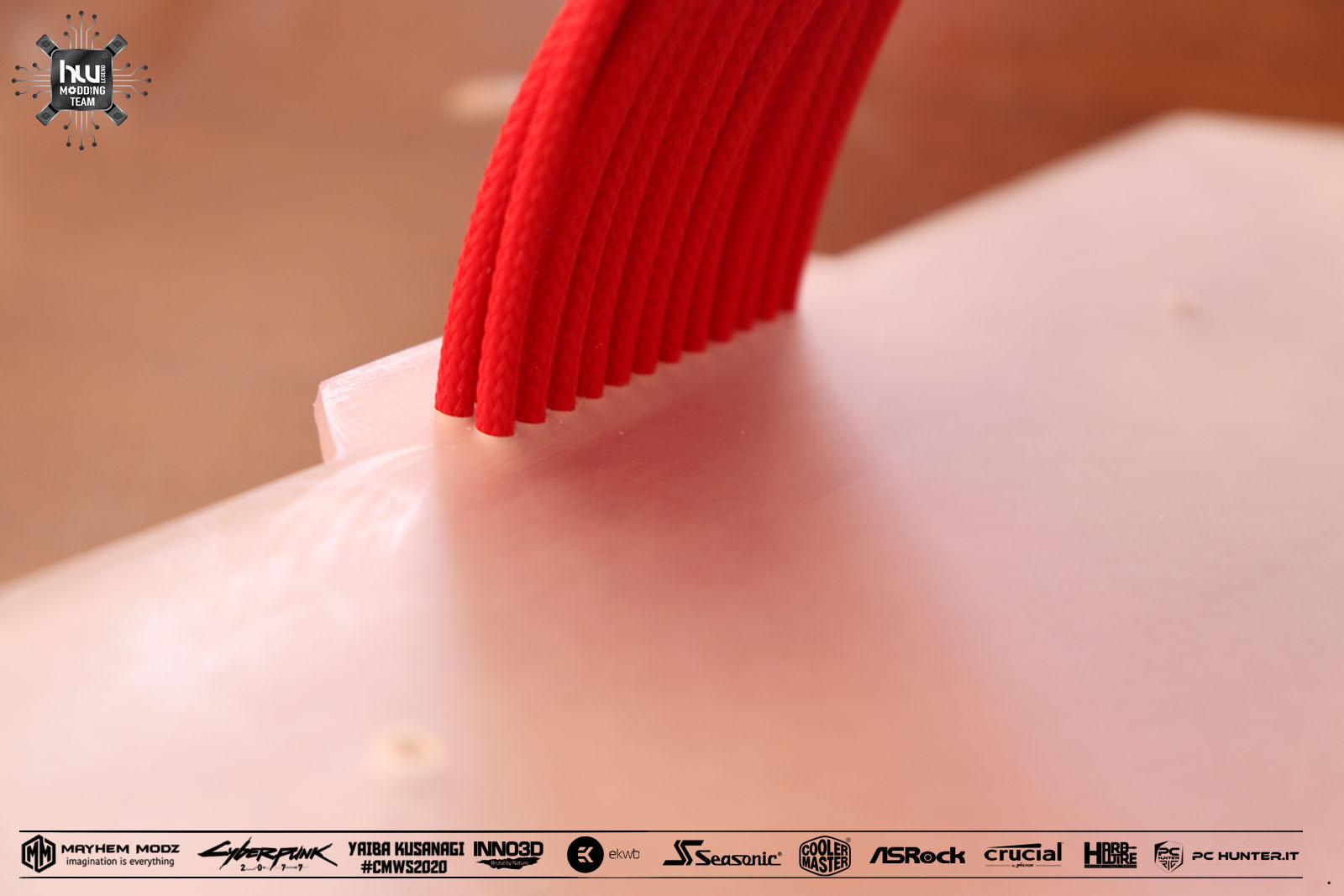

cable mod hardwire

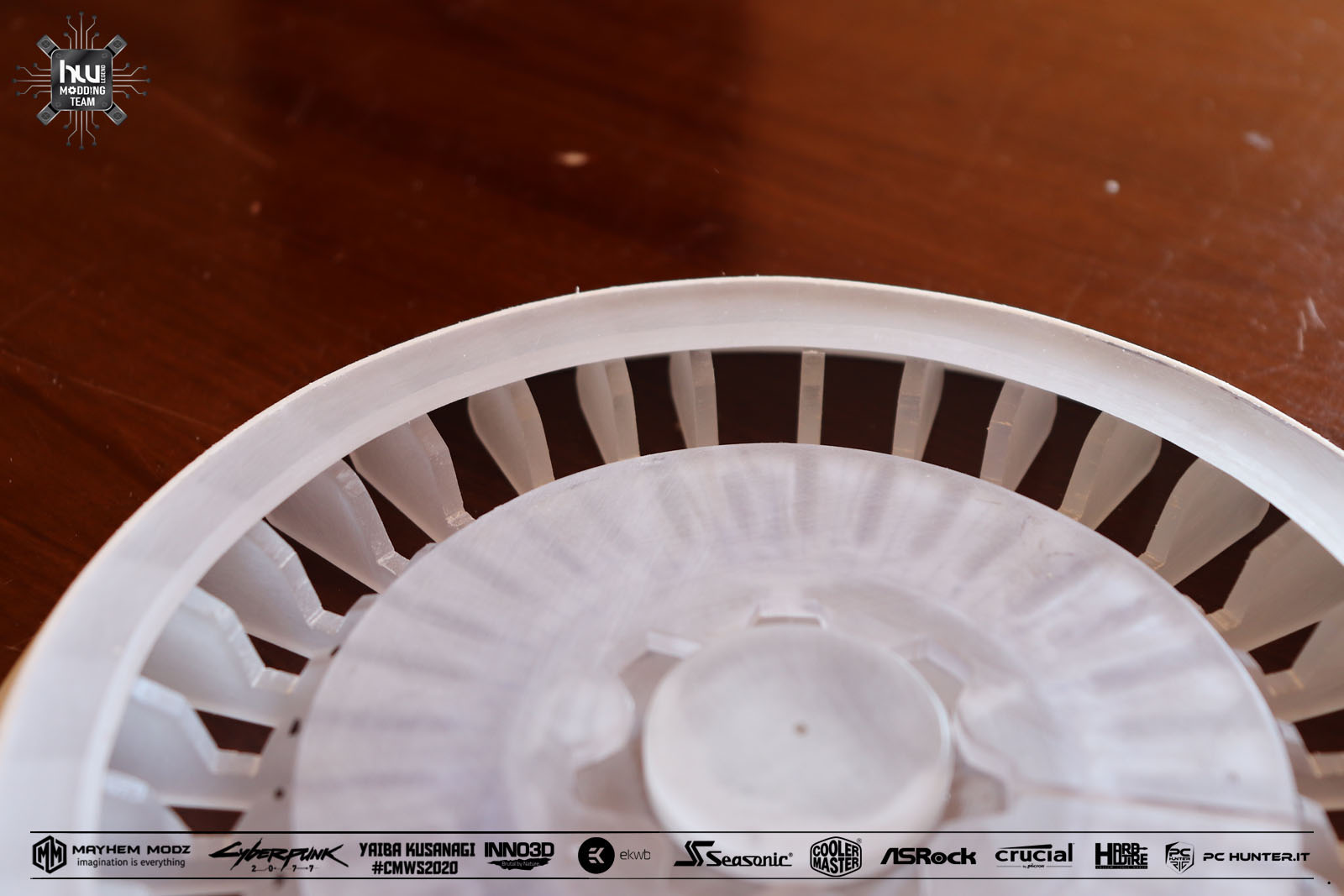

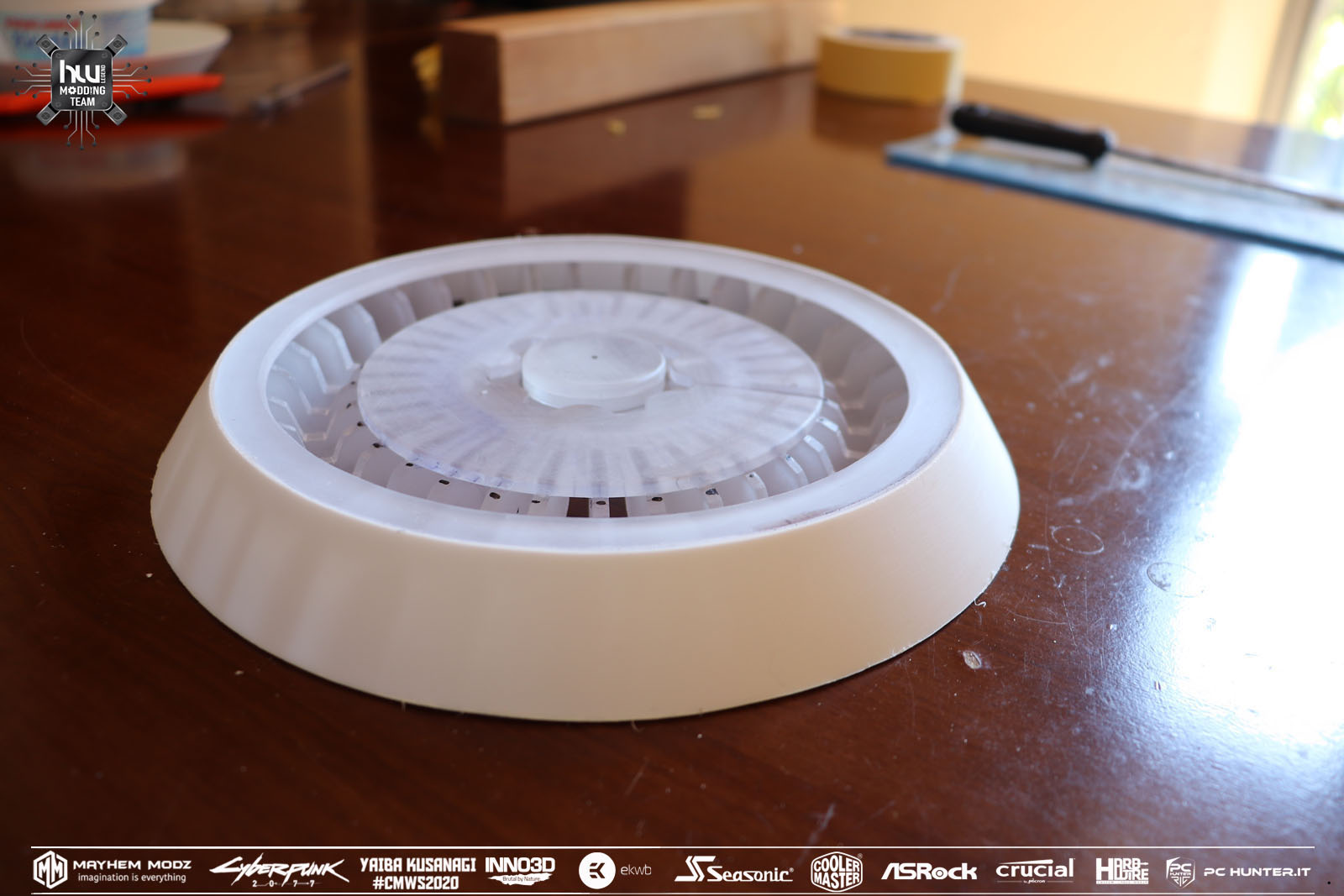

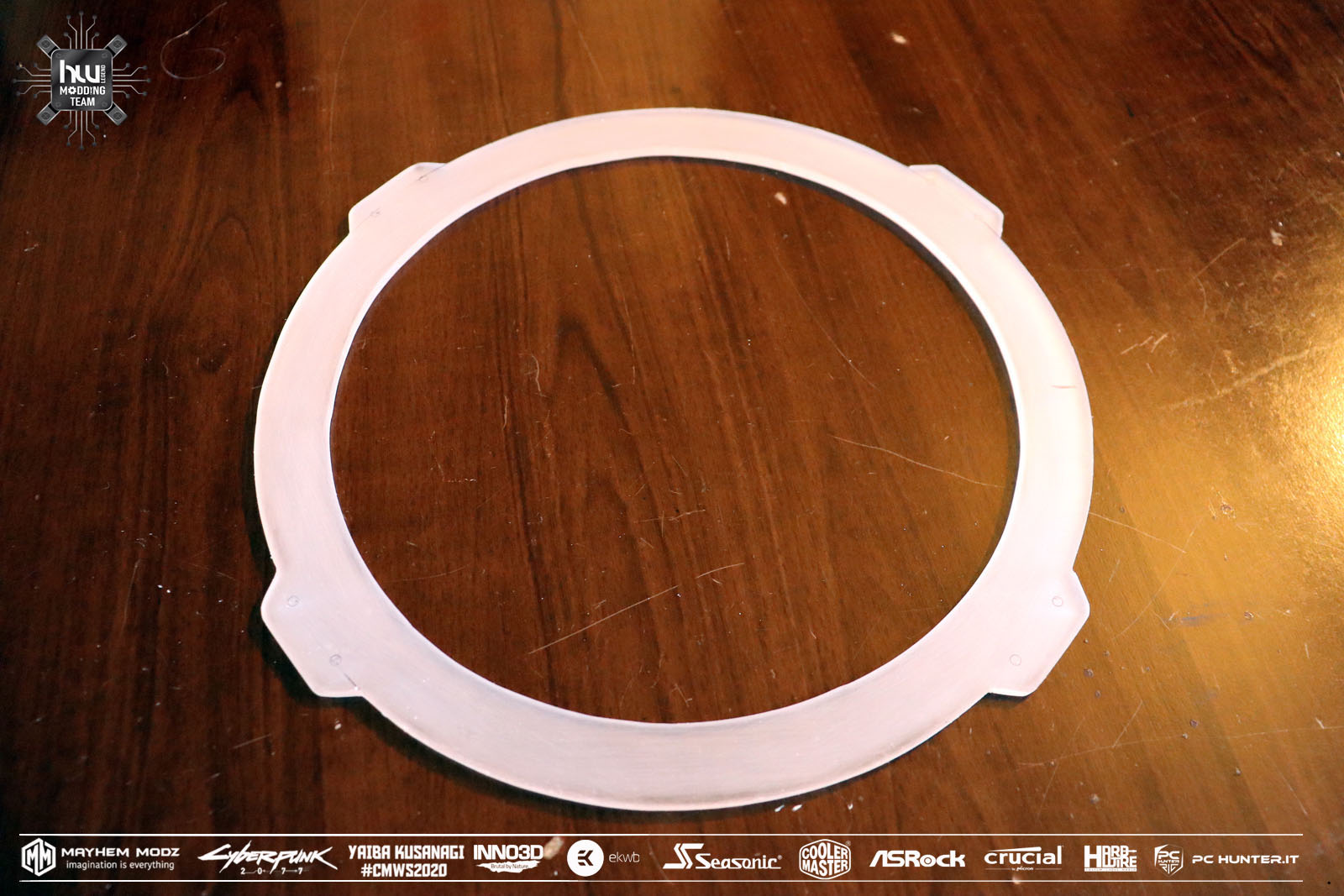

addictional fan coolermaster 200 MF R RGB

thanks to my sponsors

ASROCK, INNO3D, CRUCIAL, SEASONIC, EKWB, HARDWIRE, COOLERMASTER, PC HUNTER

configuration

motherboard asrock Z390M PRO 4

cpu intel core I7 9700KF

gpu inno3d geforce rtx 2080 super twin x2 oc

cooling EKWB custom loop

crucial memory ballistix max 32 gb kit

crucial memory ssdmx500 x2

crucial memory M2 1TB P1

psu seasonic prime PX850W

cable mod hardwire

addictional fan coolermaster 200 MF R RGB