Compound removal

Overview

I thought people would benefit from both an understanding of 'how' to remove ICD and irrefutable proof that IC Diamond does not damage the IHS markings.

A test model was developed to demonstrate a worst case contact scenario of a high pressure heat sink/IHS mount with IC Diamond as the interface material against surface coating fragile enough to be an indicator of surface polishing under extreme conditions

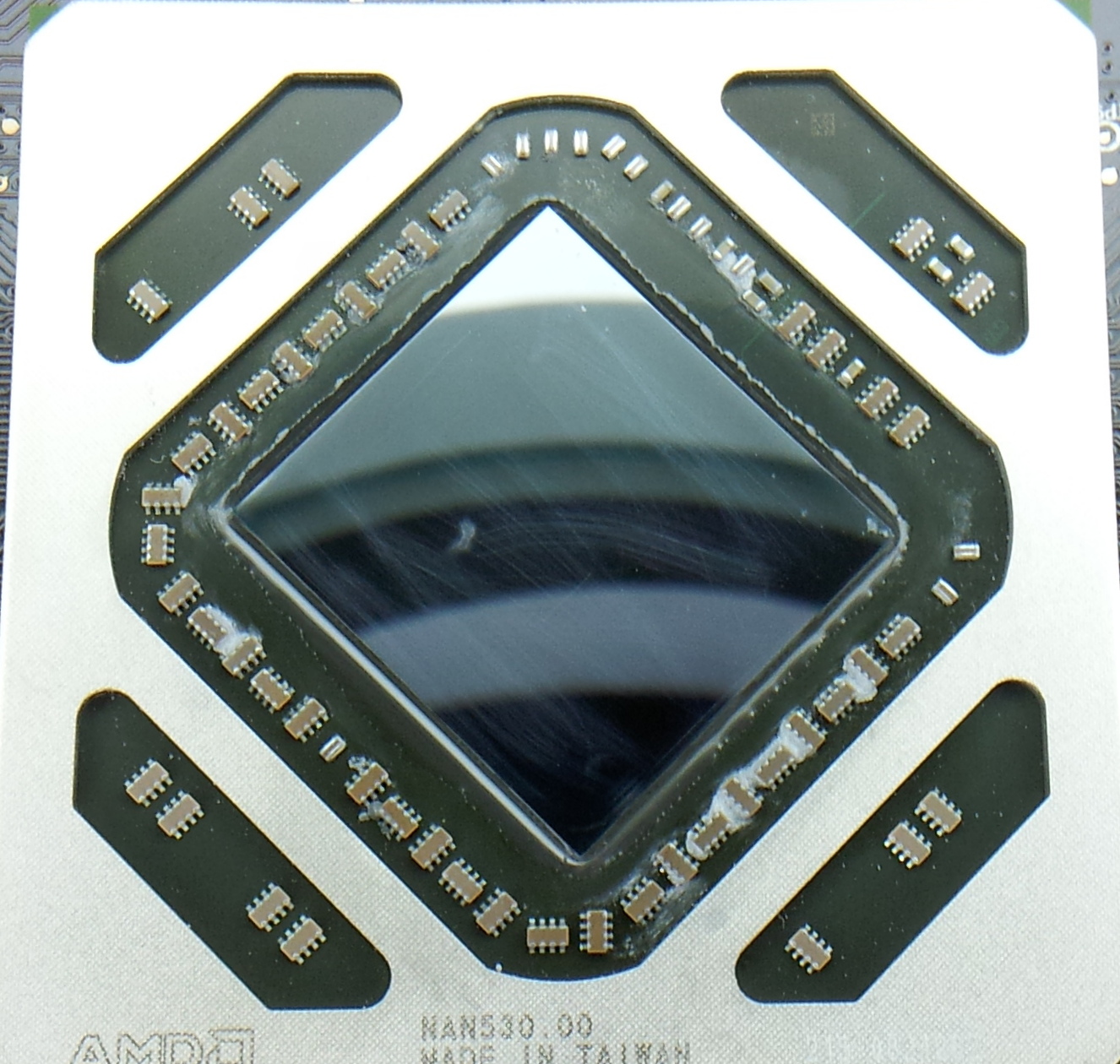

For a demonstration to prove that IC Diamond does not damage IHS markings we needed a surface coating/finish that was much thinner than the 1 or 2 micron lettering found on Intel and AMD IHS. A number of potential candidates were ruled out. Paint was no good as it reacted to solvents on a clean up and was too thick thinner, non reactive coatings Like AR (anti reflective) and anodized aluminum while thin enough, were too hard for an adequate comparison.

We finally settled on an oxidized copper sheet. Copper oxidation growth in an open, natural, rural weather environment proceeds at a very slow rate of perhaps .5 microns a year . So on some copper sheet that's been sitting around in our lab a couple of years and in an interior , air - conditioned environment, you can anticipate oxide growth to be 1/10 of an exterior exposure. We had the ideal situation, oxidized copper with a coating of .1 to .2 microns. and with IHS serial markings that have a estimated thickness of just 1 to 2 microns, the copper oxide coating represents approx 10-20 % the thickness of the the manufacturer serial markings, Additionally is soft enough to polish back to its original shine with nothing more abrasive than a finger, in less than 5 seconds.

Below is the selected copper sheet

http://i291.photobucket.com/albums/ll300/ICD7/5X5copperoxidetestplate.png

Test Model

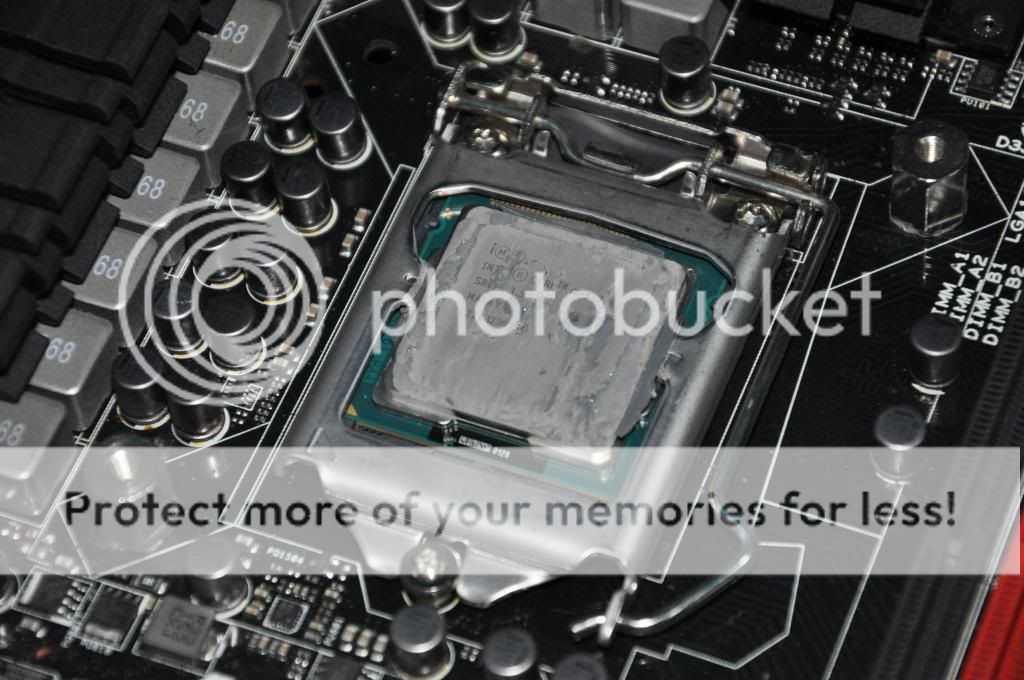

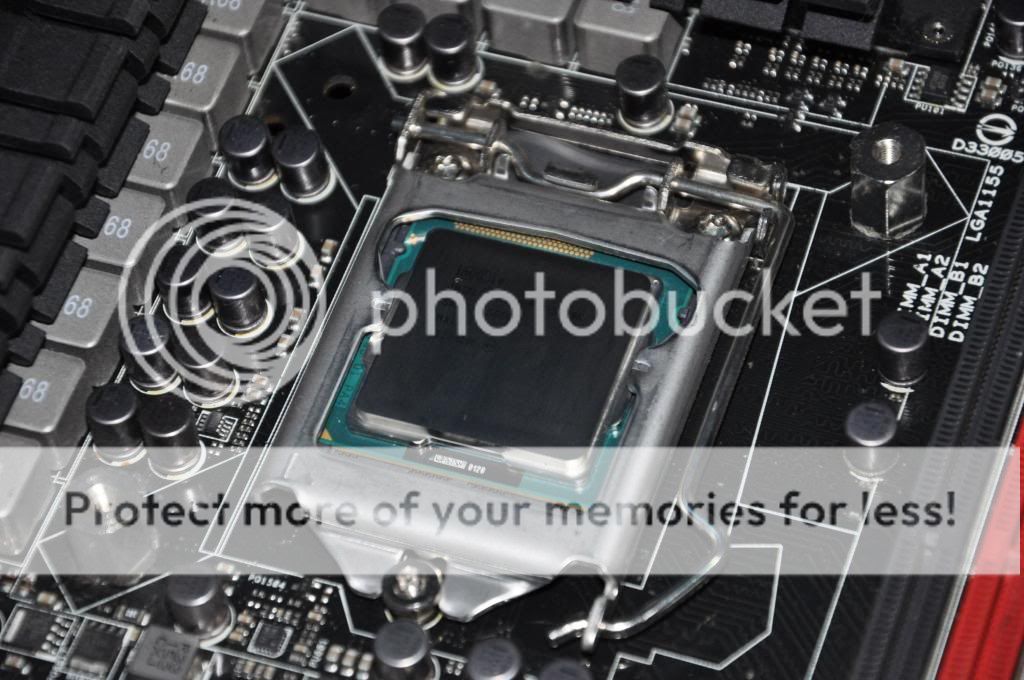

Picture of the test set up

http://i291.photobucket.com/albums/ll300/ICD7/testsetup.png

The complete set materials/components used here are

1) A 150 lb. Digital shipping scale

2) 2 pony 40 lb. spring clamps

3) 1 tube of IC Diamond 24

4) One 5X5 1.35 mm thick oxidized copper sheet

5) One 30mm X 3mm thick copper block to model base heat sink contact

Test Description

The test set up simulates application of IC Diamond on a contact area approximately equal to to an IHS on a 5 X 5 inch oxidized copper sheet.

The copper oxide simulates, at a lower extreme, the 1-2 micron thickness of manufacturers serial markings which are 80 to 90% thicker by comparison to the oxide surface finish.

The 30mm X 3mm thick copper block is to model base heat sink contact to which the IC diamond compound is applied.

IC Diamond is then applied to the 30mm square modeled heat sink base and clamped with the spring clamps to the test piece a together at the maximum clamp jaw extension of close to 2 inches to the scale to simulate what you would experience with a heat sink and IHS contacted under pressure with IC Diamond as an interface.

Test notes:

This test case represents an extreme worst case scenario, room temperature, copper oxide surface finishes are very different from high temperature thermally generated ones and are easily marked with sub copper MOHS (3) hard materials like a fingernail, paper, piece of wood, etc.

Applied pressure is also worst case scenario, 4lbs. above board specified loads and 30lbs above user averages.

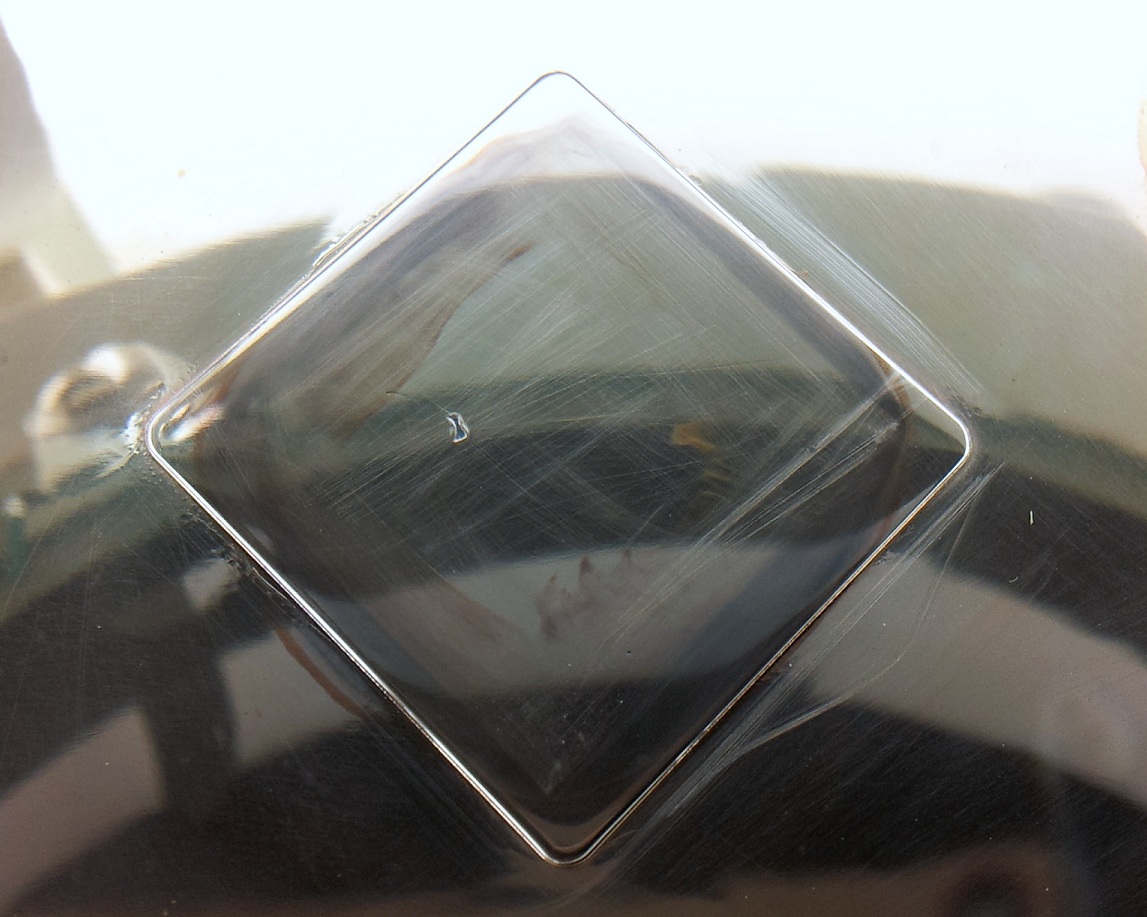

Close up view of the test area to note prior to the test pre existing scuffs and scratches

http://i291.photobucket.com/albums/ll300/ICD7/5X5copperoxidetestplatecloseup.png

Application of Compound – note process mark

http://i291.photobucket.com/albums/ll300/ICD7/ICDiamondonsimulatedsink.png

With the pony Clamps applied, a pressure of 79lbs (

4lbs higher than Intel max board load specification) is in place and compound can be seen to be squeezed out the sides.

http://i291.photobucket.com/albums/ll300/ICD7/clamppressure79lbs.png

Disassembled test -slight finish smear under the #1 process mark when applying the first clamp the piece moved.

http://i291.photobucket.com/albums/ll300/ICD7/unmountedtestwithcompound.png

Compound re-liquefied with acetone.

http://i291.photobucket.com/albums/ll300/ICD7/reliquifyingthecompound.png

Compound removal

Solvents in thermal compound removal are used to replace and/or ease mechanical action required to remove a material that has good mechanical adhesion (good mechanical contact = good thermal transfer).

Most thermal compounds have exactly the same primary ingredient ( Aluminum oxide) as a lapping compound or sandpaper (Aluminum oxide), while diamond is hard (MOHS 10) it is only incrementally so, aluminum oxide (mohs 9) is actually the preferred cutting agent used by the glass industry. According to these products MSDS's Shin Etsu, AS5, MX4 etc. all contain significant %'s of aluminum oxide.

Despite the highly abrasive nature of these materials when correctly applied and removed no issues should be encountered. Countless how-to videos have been observed by Innovation Cooling where the presenter squirts out some cleaning agent and then begins to vigorously scrub the piece much like they cleaning a frying pan. This clearly shows a lack of understanding of basic, common shop practice.

Good shop practice is to let the solvent do the mechanical work to re-liquefy and remove the compound as above by blotting with a solvent saturated paper towel till compound is fully dissolved . Once dissolved, the compound is lifted or loosened from the contact surface *and easily removed with a single wipe or two without abrasion. This works with even the hardest most dried out compound it just requires a little more patience.

Below is the cleaned piece with no evidence of any marking or damage to the .1-.2 micron thick surface

http://i291.photobucket.com/albums/ll300/ICD7/Cleanedandnodamage.png

Note that the surface is so thin and delicate that nothing more abrasive than a finger can polish it back to it's original shine in under 5 seconds

http://i291.photobucket.com/albums/ll300/ICD7/Fingerpolishcopperoxide.png

Summary Conclusion

Under extreme conditions the test performed here was above the manufacturer's maximum load specifications on a material much softer than manufacturer's serial markings on an IHS (as an at home test try removing the markings on your CPU with finger abrasion) and on the order of 10-20% of the thickness of typical IHS markings.

Final test result showed no scratches, no polishing and no visible abrasion of any kind.

When the compound is properly applied and removed, the typical high end user will experience zero problems with multiple heat sink mounts and dismounts independent of any external mechanical factors not related to recommended thermal compound application and removal procedure.

I would note that demonstrations of proper removal were performed here by one moar in his live video and FullFusion in his video posted earlier in the thread where they encountered no problems and are great examples of how to do it properly and are referenced here for those that need instruction.