5

5

EVGA SuperNOVA G2 1000 W Review

Voltage Regulation, Hold-up Time & Inrush Current »A Look Inside & Component Analysis

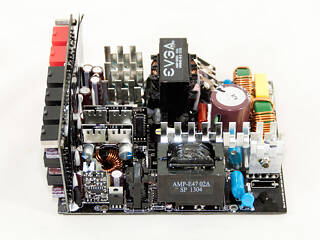

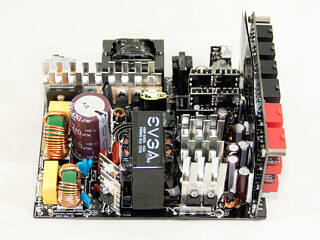

Before reading this page, we strongly suggest a look at this article, which will help you understand the internal components of a PSU much better. Our main tool for the disassembly of the PSU is a Thermaltronics TMT-9000S soldering and rework station. It is of extreme quality and is equipped with a matching de-soldering gun. With such equipment in hand, breaking apart every PSU is like a walk in the park!The OEM of this unit is Super Flower. The exact same platform is used by their new Platinum certified Leadex PSU. EVGA apparently chose to lower the efficiency in order to offer a lower price. The primary side uses a resonant converter to boost efficiency. Active components on the secondary side rectify the +12V rail that feeds two DC-DC converters which generate the minor rails. The design is in general very clean, and its heatsinks and the polymer caps that filter the +12V rail in the secondary side actually reminded us of Seasonic's Platinum units.

The transient filtering stage starts with a single X cap at the AC receptacle. It continues on the main PCB with two CM chokes, two X xaps, two pairs of Y caps, and an MOV. We also found a Transient Voltage Suppression (TVS) diode, so the protection against spikes is adequate.

The two parallel bridge rectifiers are bolted to the APFC heatsink, and an additional smaller heatsink is attached to one of them.

In the APFC section, we spotted three Infineon IPP50R199CP fets along with a C3D10060A boost diode. The two parallel hold-up caps are located right in front of the transient filter and are provided by Nippon Chemi-Con (400 V, 470 μF, 105°C, KMQ series). Their combined capacity, 940 μF, is adequate for this unit, which the hold-up test will clearly show. The NTC thermistor responsible for protection against large inrush currents is near the capacitor on the main board. The small white box in front of it is an electromagnetic relay that isolates it from the circuit once it finishes its job.

This small, sealed PCB probably houses the APFC controller, a, if I had to guess, NCP1653A IC.

The standby PWM controller is an ICE3B0565 IC that is partially hidden by the APFC transformer.

The main switchers, two IPP50R250CP fets, are bolted to two small heatsinks. They apparently don't need much cooling because of the loss-less switching the LLC resonant converter provides. The main transformer in front of them carries EVGA's logo.

The LLC resonant controller is installed on this vertical daughter-board. Its marking, AA9013, didn't bring any results up on Google. It is apparently a proprietary IC similar to the SF29601 Super Flower used in their previous generation of Platinum models.

The secondary side has three small heatsinks. Two of these host eight fets in total (8x IPP041N04N). Amongst these heatsinks are six polymer Chemi-Con caps and several electrolytic caps by the same company to filter ripple.

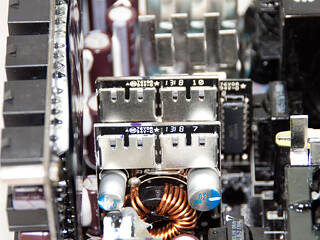

The two DC-DC converters that generate the minor rails.

We had to secure this vertical board with lots of glue because it is very easy to snap off its base if you try to detach the fan connector, and fixing that would have been very difficult. We had a bad experience with a similar daughter-board in a Super Flower unit we reviewed a while ago and made sure not to take any chances. Super Flower should secure this board better instead of solely relying on the solder points on the base.

The 5VSB rail is rectified by a Mospec S10C60C SBR (Schottky Barrier Rectifier). The fan control board is installed right next to it, and on it is an LM324ADC.

The front of the modular PCB has many Capxon polymer caps and several small electrolytic ones. Although caps in this area are never highly stressed and are, as such, of no great importance, EVGA does speak of 100% Japanese caps used on the package, and last we checked, Capxons were Chinese. Well, marketing sometimes sucks big time!

Soldering quality on the main PCB is good enough. All component leads are carefully trimmed, but Super Flower still cannot match high-end implementations of Delta, Flextronics, and Seasonic in this area.

The cooling fan is equipped with double ball-bearings and is made by Hong Hua. Its model number is HA1425M12B-Z, and it is rated for 0.36A at 12 V. The fan can achieve 1600 RPM with the aformentioned power input, but the fan controller circuit restricts its full speed to around 1485 RPM. Only with a 110% load (1100 W) and at 46°C ambient did we manage to make it spin at 1550 RPM, which is still lower than its maximum-rated speed.

Apr 26th, 2024 03:31 EDT

change timezone

Latest GPU Drivers

New Forum Posts

- Which new games will you be buying? (317)

- AMD RX 7000 series GPU Owners' Club (1088)

- Best SSD for system drive (82)

- What phone you use as your daily driver? And, a discussion of them. (1484)

- What's your latest tech purchase? (20342)

- im new to throttelstop and i think i messed it up by copying others any hints would be very much aprreciated (3)

- Horizontal black lines popping up on my screen? (4)

- Alphacool CORE 1 CPU block - bulging with danger of splitting? (20)

- Black screen after muting (5)

- What are you playing? (20530)

Popular Reviews

- Fractal Design Terra Review

- Thermalright Phantom Spirit 120 EVO Review

- Corsair 2000D Airflow Review

- ASUS GeForce RTX 4090 STRIX OC Review

- NVIDIA GeForce RTX 4090 Founders Edition Review - Impressive Performance

- ASUS GeForce RTX 4090 Matrix Platinum Review - The RTX 4090 Ti

- MSI GeForce RTX 4090 Suprim X Review

- Gigabyte GeForce RTX 4090 Gaming OC Review

- MSI GeForce RTX 4090 Gaming X Trio Review

- MSI GeForce RTX 4090 Suprim Liquid X Review

Controversial News Posts

- Sony PlayStation 5 Pro Specifications Confirmed, Console Arrives Before Holidays (117)

- Windows 11 Now Officially Adware as Microsoft Embeds Ads in the Start Menu (116)

- NVIDIA Points Intel Raptor Lake CPU Users to Get Help from Intel Amid System Instability Issues (106)

- AMD "Strix Halo" Zen 5 Mobile Processor Pictured: Chiplet-based, Uses 256-bit LPDDR5X (101)

- US Government Wants Nuclear Plants to Offload AI Data Center Expansion (98)

- AMD's RDNA 4 GPUs Could Stick with 18 Gbps GDDR6 Memory (88)

- Developers of Outpost Infinity Siege Recommend Underclocking i9-13900K and i9-14900K for Stability on Machines with RTX 4090 (85)

- Windows 10 Security Updates to Cost $61 After 2025, $427 by 2028 (84)