It looks like the powdercoating will only be done next Mon-Tuesday

In the meantime, I got my hands on an mcp35x2 top which meant I could finally see if 2 mcp35x pumps would be enough for the Mo.Ra. It chewed up a single pump when I hooked up a simple loop with reservoir, pump, compression fittings, angle adapters and the Mo.Ra- nothing else. At 50% max power as controlled by the Aquaero 6, I barely got 0.9 GPM. When I tuned it lower to 35% so the pump was at a noise level more conducive to what I would like in the final build, I got 0.6 GPM. Adding in 4 QDCs got me into laminar flow and once I add in the GPU blocks and 2 more QDCs I can only imagine how low it would go!

So anyway, I got another mcp35x pump (from a forum marketplace) which was pretty much new:

The older one on the left has a different logo. Turning one pump to the side, we see the good ol' warranty void sticker:

Speaking to Bryan over at Swiftech, I learnt it was completely fine to remove the stock tops

IF adding on the Swiftech mcp35x2 top. But the guys at Swiftech are generally understanding of other tops and will help out with RMA once they have established the 3rd party top was not the cause of any error- your mileage may definitely vary here.

So taking off that sticker leaves behind a nice trail of evidence that is hard to remove but not impossible. To remove the top, one simply has to unscrew the 4 screws at the bottom:

The new pump actually came with hex head screws, and not a very common size either. Good thing I have a multi bit driver!

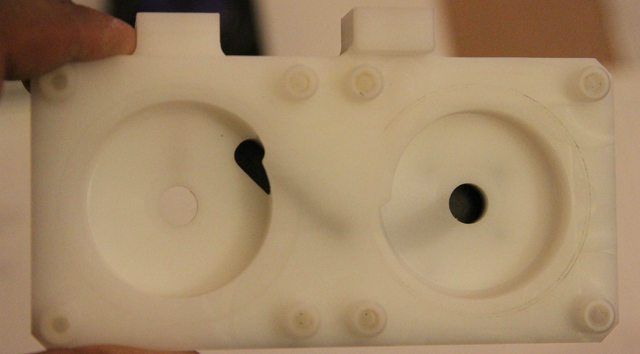

Make sure the O-rings are in place before putting on the new top. Speaking of which:

I am not set on this color yet- especially with the black interior. But that won't matter for testing here and so I put on the top, being careful to screw each pump in with the included screws and making sure there is no discernible gap between the top and the pump bodies.

This thing is a powerhouse for most loops. It is also pretty loud at full speed and caused a cyclonic noise when sucking in water from the reservoir even at 50% max power. This should not be confused with 50% duty cycle as seen from the below PWM response chart from Swiftech:

At the same kind of noise levels as before (35% power, ~50% duty cycle), I got 1.2 GPM with the Mo.Ra alone in the loop and about 0.9-1 GPM with 4 QDCs. When the mcp50x comes out, I will hopefully get 1-2 to test against these for performance and noise. Depending on what I go with for Side 2, I may have a D5 pump also for testing.

One last thing- before putting on the top, I connected both pumps in series to see how the top affects things. At lower flow rates (0.60-1 GPM), there was no discernible difference in flow rates. I will be getting an inline pressure sensor soon to see if head pressure is affected. At higher flow rates (1.2+ GPM), the top increased flow rates about about 0.1 GPM compared to having two pumps in series hooked up by fittings- at least in my case. So I can definitely vouch for going with a dual pump top each time. It also looks better in my opinion.

.

.