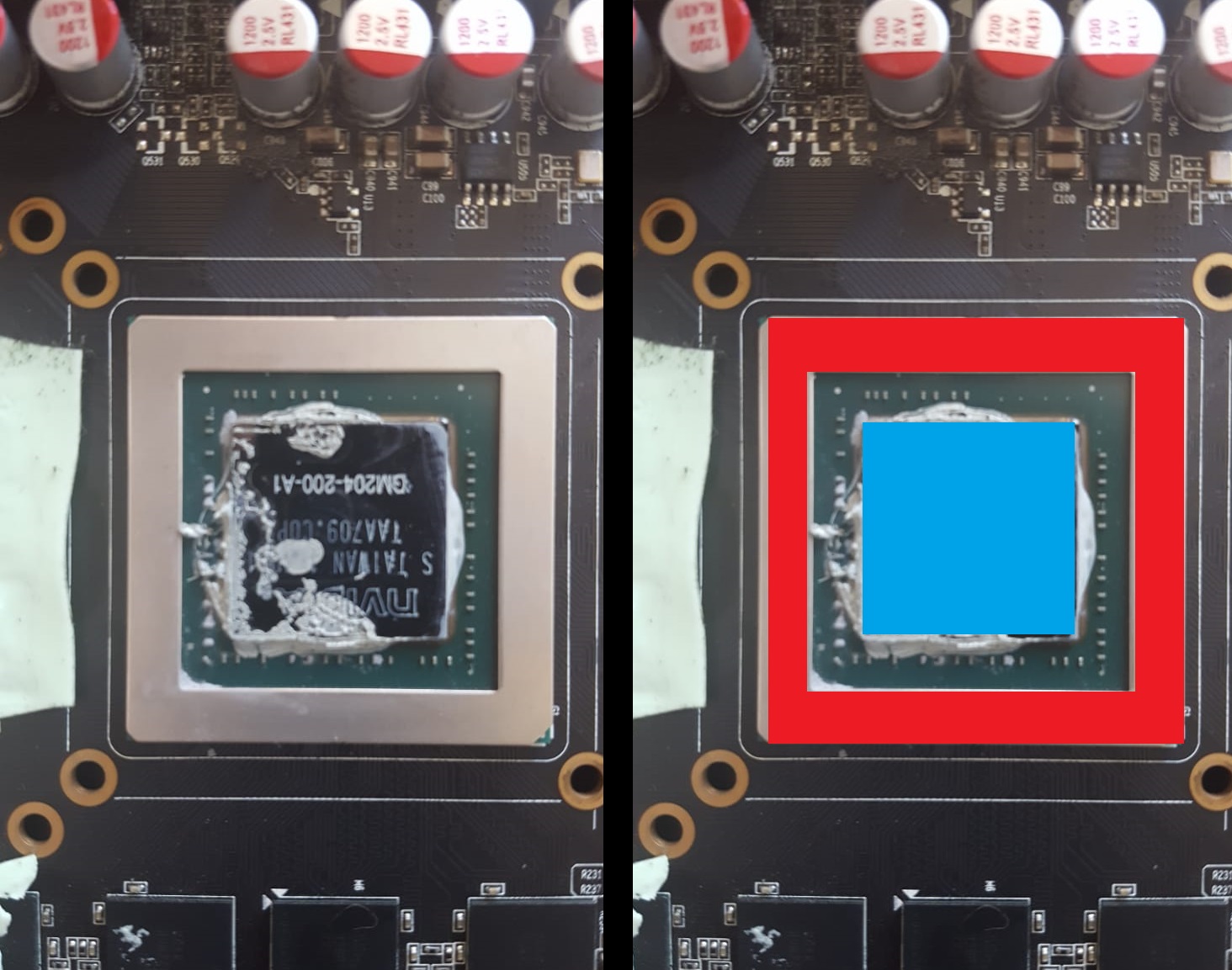

Helo guys, i was going to change the thermal paste of my GPU (Zotac GTX 970), but i noticed that the red part on the GPU Chip makes contact with the cooler of the GPU. So my question is simple, i should apply thermal paste there? Also im going to change the thermal pad with a Fujipoly 13w/mK high performance because the ones of the GPU are in pretty bad condition.

-

Welcome to TechPowerUp Forums, Guest! Please check out our forum guidelines for info related to our community.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I should apply thermal paste here?

- Thread starter valen99

- Start date

INSTG8R

Vanguard Beta Tester

- Joined

- Nov 26, 2004

- Messages

- 8,150 (1.09/day)

- Location

- Canuck in Norway

| System Name | Hellbox 5.1(same case new guts) |

|---|---|

| Processor | Ryzen 7 5800X3D |

| Motherboard | MSI X570S MAG Torpedo Max |

| Cooling | TT Kandalf L.C.S.(Water/Air)EK Velocity CPU Block/Noctua EK Quantum DDC Pump/Res |

| Memory | 2x16GB Gskill Trident Neo Z 3600 CL16 |

| Video Card(s) | Powercolor Hellhound 7900XTX |

| Storage | 970 Evo Plus 500GB 2xSamsung 850 Evo 500GB RAID 0 1TB WD Blue Corsair MP600 Core 2TB |

| Display(s) | Alienware QD-OLED 34” 3440x1440 144hz 10Bit VESA HDR 400 |

| Case | TT Kandalf L.C.S. |

| Audio Device(s) | Soundblaster ZX/Logitech Z906 5.1 |

| Power Supply | Seasonic TX~’850 Platinum |

| Mouse | G502 Hero |

| Keyboard | G19s |

| VR HMD | Oculus Quest 3 |

| Software | Win 11 Pro x64 |

Just the blue part

- Joined

- Aug 20, 2007

- Messages

- 22,215 (3.44/day)

- Location

- Olympia, WA

| System Name | Pioneer |

|---|---|

| Processor | Ryzen 9 9950X |

| Motherboard | MSI MAG X670E Tomahawk Wifi |

| Cooling | Noctua NH-D15 + A whole lotta Sunon, Phanteks and Corsair Maglev blower fans... |

| Memory | 128GB (4x 32GB) G.Skill Flare X5 @ DDR5-4200(Running 1:1:1 w/FCLK) |

| Video Card(s) | XFX RX 7900 XTX Speedster Merc 310 |

| Storage | Intel 5800X Optane 800GB boot, +2x Crucial P5 Plus 2TB PCIe 4.0 NVMe SSDs, 1x 2TB Seagate Exos 3.5" |

| Display(s) | 55" LG 55" B9 OLED 4K Display |

| Case | Thermaltake Core X31 |

| Audio Device(s) | TOSLINK->Schiit Modi MB->Asgard 2 DAC Amp->AKG Pro K712 Headphones or HDMI->B9 OLED |

| Power Supply | FSP Hydro Ti Pro 850W |

| Mouse | Logitech G305 Lightspeed Wireless |

| Keyboard | WASD Code v3 with Cherry Green keyswitches + PBT DS keycaps |

| Software | Gentoo Linux x64, other office machines run Windows 11 Enterprise |

Yep, no paste on the rim. Don't overthink it.

- Joined

- Mar 23, 2016

- Messages

- 4,915 (1.48/day)

| Processor | Intel Core i7-13700 PL2 150W |

|---|---|

| Motherboard | MSI Z790 Gaming Plus WiFi |

| Cooling | Cooler Master RGB Tower cooler |

| Memory | Crucial Pro DDR5-5600 32GB Kit OC 6600 |

| Video Card(s) | Gigabyte Radeon RX 9070 GAMING OC 16G |

| Storage | 970 EVO NVMe 500GB, WD850N 2TB |

| Display(s) | Samsung 28” 4K monitor |

| Case | Corsair iCUE 4000D RGB AIRFLOW |

| Audio Device(s) | EVGA NU Audio, Edifier Bookshelf Speakers R1280 |

| Power Supply | TT TOUGHPOWER GF A3 Gold 1050W |

| Mouse | Logitech G502 Hero |

| Keyboard | Logitech G G413 Silver |

| Software | Windows 11 Professional v24H2 |

Don't forget to clean the old paste off with 90% rubbing alcohol and coffee filters.

- Joined

- Dec 14, 2013

- Messages

- 2,760 (0.66/day)

- Location

- Alabama

| Processor | Ryzen 2600 |

|---|---|

| Motherboard | X470 Tachi Ultimate |

| Cooling | AM3+ Wraith CPU cooler |

| Memory | C.R.S. |

| Video Card(s) | GTX 970 |

| Software | Linux Peppermint 10 |

| Benchmark Scores | Never high enough |

That rim is simply to ensure the cooler's surface once mounted sits flat onto the chip's core, that's why it makes contact as it does.

Just the blue part

Thankyou guys!Yep, no paste on the rim. Don't overthink it.

Im using isopropyl alcohol 99% and cotton.Don't forget to clean the old paste off with 90% rubbing alcohol and coffee filters.

- Joined

- Mar 23, 2016

- Messages

- 4,915 (1.48/day)

| Processor | Intel Core i7-13700 PL2 150W |

|---|---|

| Motherboard | MSI Z790 Gaming Plus WiFi |

| Cooling | Cooler Master RGB Tower cooler |

| Memory | Crucial Pro DDR5-5600 32GB Kit OC 6600 |

| Video Card(s) | Gigabyte Radeon RX 9070 GAMING OC 16G |

| Storage | 970 EVO NVMe 500GB, WD850N 2TB |

| Display(s) | Samsung 28” 4K monitor |

| Case | Corsair iCUE 4000D RGB AIRFLOW |

| Audio Device(s) | EVGA NU Audio, Edifier Bookshelf Speakers R1280 |

| Power Supply | TT TOUGHPOWER GF A3 Gold 1050W |

| Mouse | Logitech G502 Hero |

| Keyboard | Logitech G G413 Silver |

| Software | Windows 11 Professional v24H2 |

Just make sure there's no cotton fibers on either surface before applying TIM.Im using isopropyl alcohol 99% and cotton

- Joined

- Jun 3, 2018

- Messages

- 911 (0.36/day)

- Location

- Al Balqa', Jordan

| Processor | AMD Ryzen 5 2600, OC: 4.0 GHz @1.3 V |

|---|---|

| Motherboard | ASRock B450 Steel Legend, BIOS Version: 10.31 [Beta] |

| Cooling | Cooler Master MasterLiquid ML120L V2 RGB, 5x Galax Vortex Wind-02 (3x Front Intake + 2x Top exhaust) |

| Memory | Kingston FURY Beast RGB 3600 MT/s 32 GB (4x 8GB), (KF436C17BBA/8) |

| Video Card(s) | Palit GeForce GTX 1660 Ti Dual OC |

| Storage | Kingston NV2 1 TB |

| Display(s) | MSI PRO M251 (HDMI), Running @104 Hz |

| Case | Cooler Master MasterBox MB520 |

| Audio Device(s) | HP H360G USB |

| Power Supply | Cooler Master MWE 550 80+ White |

| Mouse | HP G200 Black |

| Keyboard | Redragon MITRA K551-1 RGB |

| Software | Windows 11 Home |

Just put a medium dot on the middle of the die and put the heatink and forget it.

- Joined

- Jan 17, 2010

- Messages

- 12,340 (2.21/day)

- Location

- Oregon

| System Name | Juliette // My HTPC |

|---|---|

| Processor | Intel i7 9700K // AMD Ryzen 5 5600G |

| Motherboard | ASUS Prime Z390X-A // ASRock B550 ITX-AC |

| Cooling | Noctua NH-U12 Black // Stock |

| Memory | Corsair DDR4 3600 32gb //G.SKILL Trident Z Royal Series 16GB (2 x 8GB) 3600 |

| Video Card(s) | ASUS RTX4070 OC// ASUS RTX 4060 OC |

| Storage | Samsung 970 EVO NVMe 1Tb, Intel 665p Series M.2 2280 1TB // Samsung 1Tb SSD |

| Display(s) | ASUS VP348QGL 34" Quad HD 3440 x 1440 // 55" LG 4K SK8000 Series |

| Case | Seasonic SYNCRO Q7// Silverstone Granada GD05 |

| Audio Device(s) | Focusrite Scarlett 4i4 // HDMI to Samsung HW-R650 sound bar |

| Power Supply | Seasonic SYNCRO 750 W // CORSAIR Vengeance 650M |

| Mouse | G903 and a Master Mouse MM710/No mouse, MS game copntroller |

| Keyboard | EVGA / Logitech K400 |

| Software | Windows 11 Pro // Windows 10 Pro |

Just put a medium dot on the middle of the die and put the heatink and forget it.

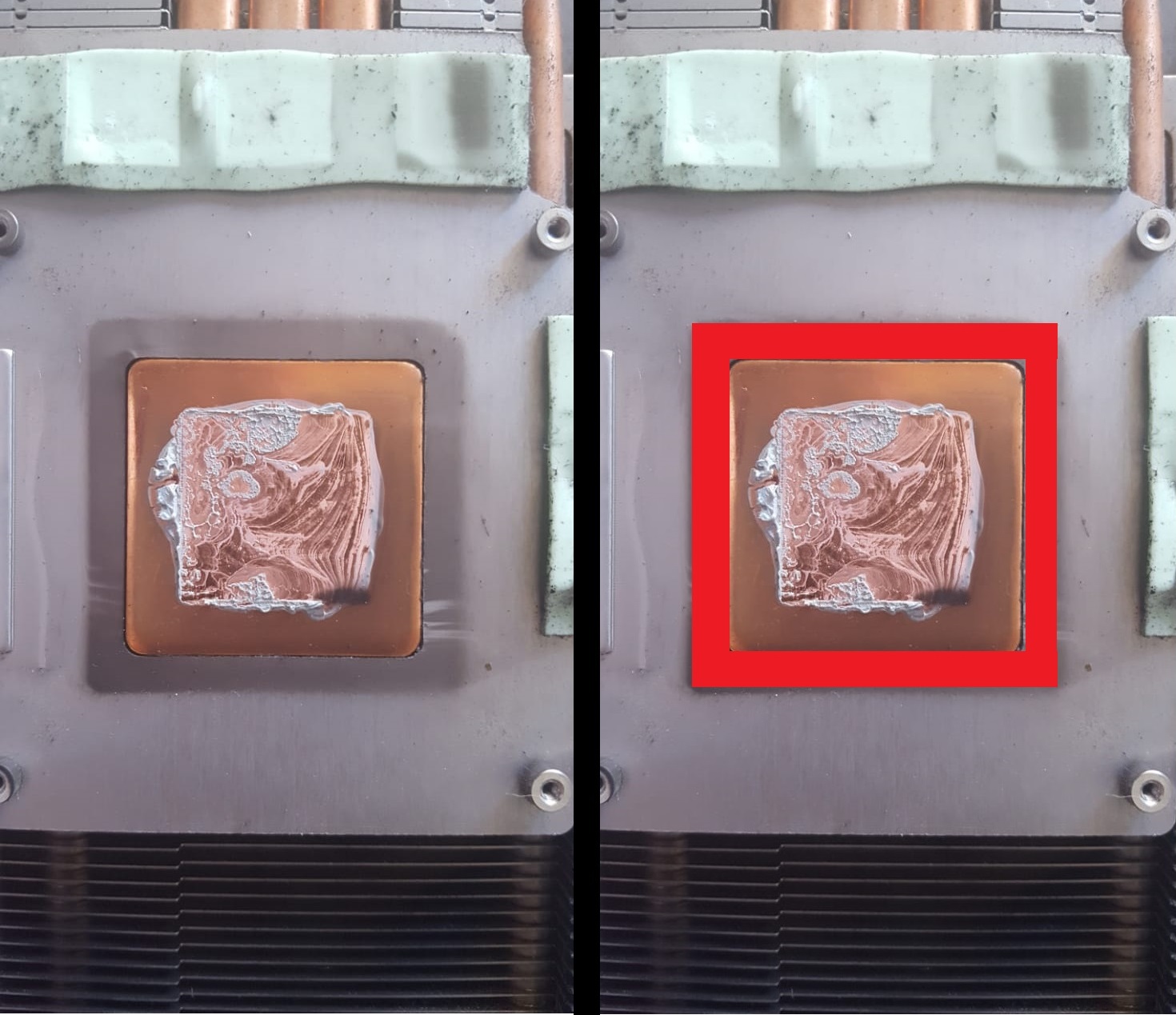

With an exposed die you want to spread it, making sure to cover the blue part completely. The single dot method is for IHS

- Joined

- Nov 24, 2018

- Messages

- 2,277 (0.97/day)

- Location

- south wales uk

| System Name | 1.FortySe7en VR rig 2. intel teliscope rig 3.MSI GP72MVR Leopard Pro .E-52699, Xeon play thing |

|---|---|

| Processor | 1.3900x @stock 2. 5950x undervolted . 3. i7 7700hq 4 E5-2699 V3 |

| Motherboard | 1.aorus x570 ultra 2. Rog b550 f,4 MR9A PRO ATX X99 |

| Cooling | 1.Hard tube loop, cpu and gpu 2. Hard loop cpu and gpu 4 360 AIO |

| Memory | 1.Gskill neo @3600 32gb 2.corsair ven 32gb @3200 3. 16gb hyperx @2400 4 64GB 2133 in quad channel |

| Video Card(s) | 1.GIGABYTE RTX 3080 WaterForce WB 2. Aorus RTX2080 3. 1060 3gb. 4 Arc 770LE 16 gb |

| Storage | 1 M.2 1tb +1tb , 2 3tb HDs 2. 1tb m.2 3tbHD 3. 256 m.2. 1tb ssd 4. 2gb ssd |

| Display(s) | 1.LG 50" UHD , 2 MSI Optix MAG342C UWHD. 3.17" 120 hz display 4. Acer Preditor 144hz 32inch.z |

| Case | 1. Thermaltake P5 2. Thermaltake P3 4. montech king 65 |

| Audio Device(s) | 1 Onboard 2 Onboard 3 Onboard 4. onboard. |

| Power Supply | 1.seasonic gx 850w 2. seasonic gx 750w. 4 RM850w |

| Mouse | 1 ROG Gladius 2 Corsair m65 pro |

| Keyboard | 1. ROG Strix Flare 2. Corsair F75 RBG 3. steelseries RBG |

| VR HMD | rift and rift S and Quest 2. rog ally 2tb m.2 1tb SD. |

| Software | 1. win11 pro 2. win11 pro 3, win11 home 4 win11 pro |

| Benchmark Scores | 1.7821 cb20 ,cb15 3442 1c 204 cpu-z 1c 539 12c 8847 |

and have a great christmas all.

FreedomEclipse

~Technological Technocrat~

- Joined

- Apr 20, 2007

- Messages

- 24,809 (3.77/day)

- Location

- (currently) Hong Kong

| System Name | WorkInProgress |

|---|---|

| Processor | AMD 7800X3D |

| Motherboard | MSI X670E GAMING PLUS |

| Cooling | Thermalright AM5 Contact Frame + Phantom Spirit 120SE |

| Memory | 2x32GB G.Skill Trident Z5 NEO DDR5 6000 CL32 |

| Video Card(s) | Asus Dual Radeon™ RX 6700 XT OC Edition |

| Storage | WD SN770 1TB (Boot)|1x WD SN850X 8TB (Gaming)| 2x2TB WD SN770| 2x2TB+2x4TB Crucial BX500 |

| Display(s) | LG GP850-B |

| Case | Corsair 760T (White) {1xCorsair ML120 Pro|5xML140 Pro} |

| Audio Device(s) | Yamaha RX-V573|Speakers: JBL Control One|Auna 300-CN|Wharfedale Diamond SW150 |

| Power Supply | Seasonic Focus GX-850 80+ GOLD |

| Mouse | Logitech G502 X |

| Keyboard | Cherry G80-3000N (TKL) |

| Software | Windows 11 Home |

| Benchmark Scores | ლ(ಠ益ಠ)ლ |

What thermal paste you going to be using? MX-4?

- Joined

- Mar 26, 2010

- Messages

- 9,923 (1.80/day)

- Location

- Jakarta, Indonesia

| System Name | micropage7 |

|---|---|

| Processor | Intel Xeon X3470 |

| Motherboard | Gigabyte Technology Co. Ltd. P55A-UD3R (Socket 1156) |

| Cooling | Enermax ETS-T40F |

| Memory | Samsung 8.00GB Dual-Channel DDR3 |

| Video Card(s) | NVIDIA Quadro FX 1800 |

| Storage | V-GEN03AS18EU120GB, Seagate 2 x 1TB and Seagate 4TB |

| Display(s) | Samsung 21 inch LCD Wide Screen |

| Case | Icute Super 18 |

| Audio Device(s) | Auzentech X-Fi Forte |

| Power Supply | Silverstone 600 Watt |

| Mouse | Logitech G502 |

| Keyboard | Sades Excalibur + Taihao keycaps |

| Software | Win 7 64-bit |

| Benchmark Scores | Classified |

wait, on die (GPU or processor) use thermal paste but vrm, memory mostly use thermalpadAlso im going to change the thermal pad with a Fujipoly 13w/mK high performance because the ones of the GPU are in pretty bad condition

Yes, im going to use a MX4 that i bought 5 months ago for my CPU.What thermal paste you going to be using? MX-4?

Yeah, im going to use the thermal pads on the vram chip. I will not change the vrm thermal pad because those are 1.5mm and i only bought 1mmwait, on die (GPU or processor) use thermal paste but vrm, memory mostly use thermalpad

Thank you!!and have a great christmas all.

I wish you a merry christmass from Argentina!

eidairaman1

The Exiled Airman

- Joined

- Jul 2, 2007

- Messages

- 44,291 (6.80/day)

- Location

- Republic of Texas (True Patriot)

| System Name | PCGOD |

|---|---|

| Processor | AMD FX 8350@ 5.0GHz |

| Motherboard | Asus TUF 990FX Sabertooth R2 2901 Bios |

| Cooling | Scythe Ashura, 2×BitFenix 230mm Spectre Pro LED (Blue,Green), 2x BitFenix 140mm Spectre Pro LED |

| Memory | 16 GB Gskill Ripjaws X 2133 (2400 OC, 10-10-12-20-20, 1T, 1.65V) |

| Video Card(s) | AMD Radeon 290 Sapphire Vapor-X |

| Storage | Samsung 840 Pro 256GB, WD Velociraptor 1TB |

| Display(s) | NEC Multisync LCD 1700V (Display Port Adapter) |

| Case | AeroCool Xpredator Evil Blue Edition |

| Audio Device(s) | Creative Labs Sound Blaster ZxR |

| Power Supply | Seasonic 1250 XM2 Series (XP3) |

| Mouse | Roccat Kone XTD |

| Keyboard | Roccat Ryos MK Pro |

| Software | Windows 7 Pro 64 |

Just make sure there's no cotton fibers on either surface before applying TIM.

Contact cleaner or co2 duster

newtekie1

Semi-Retired Folder

- Joined

- Nov 22, 2005

- Messages

- 28,473 (4.01/day)

- Location

- Indiana, USA

| Processor | Intel Core i7 10850K@5.2GHz |

|---|---|

| Motherboard | AsRock Z470 Taichi |

| Cooling | Corsair H115i Pro w/ Noctua NF-A14 Fans |

| Memory | 32GB DDR4-3600 |

| Video Card(s) | RTX 2070 Super |

| Storage | 500GB SX8200 Pro + 8TB with 1TB SSD Cache |

| Display(s) | Acer Nitro VG280K 4K 28" |

| Case | Fractal Design Define S |

| Audio Device(s) | Onboard is good enough for me |

| Power Supply | eVGA SuperNOVA 1000w G3 |

| Software | Windows 10 Pro x64 |

With an exposed die you want to spread it, making sure to cover the blue part completely. The single dot method is for IHS

Never spread thermal past, not on an IHS, not on an exposed die. Spreading introduces air bubbles. The weight of the cooler will spread the paste for you.

- Joined

- Jan 31, 2010

- Messages

- 5,685 (1.02/day)

- Location

- Gougeland (NZ)

| System Name | Cumquat 2021 |

|---|---|

| Processor | AMD RyZen R7 7800X3D |

| Motherboard | Asus Strix X670E - E Gaming WIFI |

| Cooling | Deep Cool LT720 + CM MasterGel Pro TP + Lian Li Uni Fan V2 |

| Memory | 32GB GSkill Trident Z5 Neo 6000 |

| Video Card(s) | PowerColor HellHound RX7800XT 2550cclk/2450mclk |

| Storage | 1x Adata SX8200PRO NVMe 1TB gen3 x4 1X Samsung 980 Pro NVMe Gen 4 x4 1TB, 12TB of HDD Storage |

| Display(s) | AOC 24G2 IPS 144Hz FreeSync Premium 1920x1080p |

| Case | Lian Li O11D XL ROG edition |

| Audio Device(s) | RX7800XT via HDMI + Pioneer VSX-531 amp Technics 100W 5.1 Speaker set |

| Power Supply | EVGA 1000W G5 Gold |

| Mouse | Logitech G502 Proteus Core Wired |

| Keyboard | Logitech G915 Wireless |

| Software | Windows 11 X64 PRO (build 24H2) |

| Benchmark Scores | it sucks even more less now ;) |

Never spread thermal past, not on an IHS, not on an exposed die. Spreading introduces air bubbles. The weight of the cooler will spread the paste for you.

yeah bollocks I've tried both ways and got the same result on my CPU's IHS haven't needed to do the GPU yet but will try both just to see

- Joined

- Jan 17, 2010

- Messages

- 12,340 (2.21/day)

- Location

- Oregon

| System Name | Juliette // My HTPC |

|---|---|

| Processor | Intel i7 9700K // AMD Ryzen 5 5600G |

| Motherboard | ASUS Prime Z390X-A // ASRock B550 ITX-AC |

| Cooling | Noctua NH-U12 Black // Stock |

| Memory | Corsair DDR4 3600 32gb //G.SKILL Trident Z Royal Series 16GB (2 x 8GB) 3600 |

| Video Card(s) | ASUS RTX4070 OC// ASUS RTX 4060 OC |

| Storage | Samsung 970 EVO NVMe 1Tb, Intel 665p Series M.2 2280 1TB // Samsung 1Tb SSD |

| Display(s) | ASUS VP348QGL 34" Quad HD 3440 x 1440 // 55" LG 4K SK8000 Series |

| Case | Seasonic SYNCRO Q7// Silverstone Granada GD05 |

| Audio Device(s) | Focusrite Scarlett 4i4 // HDMI to Samsung HW-R650 sound bar |

| Power Supply | Seasonic SYNCRO 750 W // CORSAIR Vengeance 650M |

| Mouse | G903 and a Master Mouse MM710/No mouse, MS game copntroller |

| Keyboard | EVGA / Logitech K400 |

| Software | Windows 11 Pro // Windows 10 Pro |

Paste has instructions. But simply put to insure coverage on the corners of a die with without getting paste on the substrate you need to spread it. With a IHS sure I agree, I never spread thatNever spread thermal past, not on an IHS, not on an exposed die. Spreading introduces air bubbles. The weight of the cooler will spread the paste for you.

http://www.arcticsilver.com/instructions.htm

Last edited:

newtekie1

Semi-Retired Folder

- Joined

- Nov 22, 2005

- Messages

- 28,473 (4.01/day)

- Location

- Indiana, USA

| Processor | Intel Core i7 10850K@5.2GHz |

|---|---|

| Motherboard | AsRock Z470 Taichi |

| Cooling | Corsair H115i Pro w/ Noctua NF-A14 Fans |

| Memory | 32GB DDR4-3600 |

| Video Card(s) | RTX 2070 Super |

| Storage | 500GB SX8200 Pro + 8TB with 1TB SSD Cache |

| Display(s) | Acer Nitro VG280K 4K 28" |

| Case | Fractal Design Define S |

| Audio Device(s) | Onboard is good enough for me |

| Power Supply | eVGA SuperNOVA 1000w G3 |

| Software | Windows 10 Pro x64 |

Let just say we disagree. Paste has instructions. But simply put to insure coverage on the corners of a die with without getting paste on the substrate you need to spread it. With a IHS sure I agree

http://www.arcticsilver.com/instructions.htm

1. Spreading doesn't prevent the paste from getting on the substrate. The paste will still spread out onto the substrate with the pressure of the cooler.

2. Paste on the substrate doesn't hurt anything. Every GPU I've ever re-pasted comes from the factory with paste all over the substrate.

AS is an exception because their paste can cause damage if it touches parts on the substrate, and because the crap is so thick it really doesn't spread right under the weight of the cooler. But no one should be using that garbage anymore anyway...

And the instructions from Arctic for the MX4 the OP has says to use the dot method no matter what.

Last edited:

- Joined

- Jan 31, 2010

- Messages

- 5,685 (1.02/day)

- Location

- Gougeland (NZ)

| System Name | Cumquat 2021 |

|---|---|

| Processor | AMD RyZen R7 7800X3D |

| Motherboard | Asus Strix X670E - E Gaming WIFI |

| Cooling | Deep Cool LT720 + CM MasterGel Pro TP + Lian Li Uni Fan V2 |

| Memory | 32GB GSkill Trident Z5 Neo 6000 |

| Video Card(s) | PowerColor HellHound RX7800XT 2550cclk/2450mclk |

| Storage | 1x Adata SX8200PRO NVMe 1TB gen3 x4 1X Samsung 980 Pro NVMe Gen 4 x4 1TB, 12TB of HDD Storage |

| Display(s) | AOC 24G2 IPS 144Hz FreeSync Premium 1920x1080p |

| Case | Lian Li O11D XL ROG edition |

| Audio Device(s) | RX7800XT via HDMI + Pioneer VSX-531 amp Technics 100W 5.1 Speaker set |

| Power Supply | EVGA 1000W G5 Gold |

| Mouse | Logitech G502 Proteus Core Wired |

| Keyboard | Logitech G915 Wireless |

| Software | Windows 11 X64 PRO (build 24H2) |

| Benchmark Scores | it sucks even more less now ;) |

AS is an exception because their paste can cause damage if it touches parts on the substrate

spreading FUD much... AS is non conductive and only ever so slightly capacitative and still does a fine job even for not top of the heap anymore

The paste will still spread out onto the substrate with the pressure of the cooler.

also NO well maybe if you use way to much then it will but I've never had it do that ever and I use the spread method on my CPU's IHS

newtekie1

Semi-Retired Folder

- Joined

- Nov 22, 2005

- Messages

- 28,473 (4.01/day)

- Location

- Indiana, USA

| Processor | Intel Core i7 10850K@5.2GHz |

|---|---|

| Motherboard | AsRock Z470 Taichi |

| Cooling | Corsair H115i Pro w/ Noctua NF-A14 Fans |

| Memory | 32GB DDR4-3600 |

| Video Card(s) | RTX 2070 Super |

| Storage | 500GB SX8200 Pro + 8TB with 1TB SSD Cache |

| Display(s) | Acer Nitro VG280K 4K 28" |

| Case | Fractal Design Define S |

| Audio Device(s) | Onboard is good enough for me |

| Power Supply | eVGA SuperNOVA 1000w G3 |

| Software | Windows 10 Pro x64 |

spreading FUD much... AS is non conductive and only ever so slightly capacitative and still does a fine job even for not top of the heap anymore

It isn't FUD, it is the truth. Do you know what capacities means? It can cause damage to electronic components if it contacts them. It does not have to be electrically conductive to do that. Look up what capacitive means. Have you ever heard how static shock can kill computer components? Guess what causes static shock. Capacitance.

And I never said it didn't do a good job cooling, it still does. It's garbage for other reasons. There are waaaay better pastes out there. Pastes that aren't thick as a turd, pastes that aren't capacitive, pastes that perform better, pastes that don't have a 200 hour break in period. etc.

AS5 is an 80 year old man that thinks he can still play professional hockey just because he can still ice skate, and for some reason he has fans that think so too...

I guarantee you, that if you have every used the spread method properly, paste has seeped out from between the die and cooler. It might have stuck to the cooler instead of the substrate, but it seeped out. It is never really enough to come close to any of the components on the substrate, but it happens. But, again, it doesn't really matter, because paste on the substrate is not a problem.also NO well maybe if you use way to much then it will but I've never had it do that ever and I use the spread method on my CPU's IHS

But I'm not turning this into a discussion on AS5, because the OP is using MX4. So follow the directions from Arctic, and all will be good.

eidairaman1

The Exiled Airman

- Joined

- Jul 2, 2007

- Messages

- 44,291 (6.80/day)

- Location

- Republic of Texas (True Patriot)

| System Name | PCGOD |

|---|---|

| Processor | AMD FX 8350@ 5.0GHz |

| Motherboard | Asus TUF 990FX Sabertooth R2 2901 Bios |

| Cooling | Scythe Ashura, 2×BitFenix 230mm Spectre Pro LED (Blue,Green), 2x BitFenix 140mm Spectre Pro LED |

| Memory | 16 GB Gskill Ripjaws X 2133 (2400 OC, 10-10-12-20-20, 1T, 1.65V) |

| Video Card(s) | AMD Radeon 290 Sapphire Vapor-X |

| Storage | Samsung 840 Pro 256GB, WD Velociraptor 1TB |

| Display(s) | NEC Multisync LCD 1700V (Display Port Adapter) |

| Case | AeroCool Xpredator Evil Blue Edition |

| Audio Device(s) | Creative Labs Sound Blaster ZxR |

| Power Supply | Seasonic 1250 XM2 Series (XP3) |

| Mouse | Roccat Kone XTD |

| Keyboard | Roccat Ryos MK Pro |

| Software | Windows 7 Pro 64 |

I think the only wrong method is putting way too much on.

If anything I used the spread method for both AS5 and MX4 on raw die and ihs parts, no problems. I think the reason they say do the method different is so not too much compound is used or some users can't spread correctly so it is easier to do it the other way.

If anything I used the spread method for both AS5 and MX4 on raw die and ihs parts, no problems. I think the reason they say do the method different is so not too much compound is used or some users can't spread correctly so it is easier to do it the other way.

- Joined

- Jan 17, 2010

- Messages

- 12,340 (2.21/day)

- Location

- Oregon

| System Name | Juliette // My HTPC |

|---|---|

| Processor | Intel i7 9700K // AMD Ryzen 5 5600G |

| Motherboard | ASUS Prime Z390X-A // ASRock B550 ITX-AC |

| Cooling | Noctua NH-U12 Black // Stock |

| Memory | Corsair DDR4 3600 32gb //G.SKILL Trident Z Royal Series 16GB (2 x 8GB) 3600 |

| Video Card(s) | ASUS RTX4070 OC// ASUS RTX 4060 OC |

| Storage | Samsung 970 EVO NVMe 1Tb, Intel 665p Series M.2 2280 1TB // Samsung 1Tb SSD |

| Display(s) | ASUS VP348QGL 34" Quad HD 3440 x 1440 // 55" LG 4K SK8000 Series |

| Case | Seasonic SYNCRO Q7// Silverstone Granada GD05 |

| Audio Device(s) | Focusrite Scarlett 4i4 // HDMI to Samsung HW-R650 sound bar |

| Power Supply | Seasonic SYNCRO 750 W // CORSAIR Vengeance 650M |

| Mouse | G903 and a Master Mouse MM710/No mouse, MS game copntroller |

| Keyboard | EVGA / Logitech K400 |

| Software | Windows 11 Pro // Windows 10 Pro |

And the instructions from Arctic for the MX4 the OP has says to use the dot method no matter what.

No it does'nt , It says both methods are fine

https://www.arctic.ac/us_en/mx-4.html

eidairaman1

The Exiled Airman

- Joined

- Jul 2, 2007

- Messages

- 44,291 (6.80/day)

- Location

- Republic of Texas (True Patriot)

| System Name | PCGOD |

|---|---|

| Processor | AMD FX 8350@ 5.0GHz |

| Motherboard | Asus TUF 990FX Sabertooth R2 2901 Bios |

| Cooling | Scythe Ashura, 2×BitFenix 230mm Spectre Pro LED (Blue,Green), 2x BitFenix 140mm Spectre Pro LED |

| Memory | 16 GB Gskill Ripjaws X 2133 (2400 OC, 10-10-12-20-20, 1T, 1.65V) |

| Video Card(s) | AMD Radeon 290 Sapphire Vapor-X |

| Storage | Samsung 840 Pro 256GB, WD Velociraptor 1TB |

| Display(s) | NEC Multisync LCD 1700V (Display Port Adapter) |

| Case | AeroCool Xpredator Evil Blue Edition |

| Audio Device(s) | Creative Labs Sound Blaster ZxR |

| Power Supply | Seasonic 1250 XM2 Series (XP3) |

| Mouse | Roccat Kone XTD |

| Keyboard | Roccat Ryos MK Pro |

| Software | Windows 7 Pro 64 |

To me It makes me want to give the hsf 1 twist right and left for the 5 dot and x then clamp it.

- Joined

- Jan 17, 2010

- Messages

- 12,340 (2.21/day)

- Location

- Oregon

| System Name | Juliette // My HTPC |

|---|---|

| Processor | Intel i7 9700K // AMD Ryzen 5 5600G |

| Motherboard | ASUS Prime Z390X-A // ASRock B550 ITX-AC |

| Cooling | Noctua NH-U12 Black // Stock |

| Memory | Corsair DDR4 3600 32gb //G.SKILL Trident Z Royal Series 16GB (2 x 8GB) 3600 |

| Video Card(s) | ASUS RTX4070 OC// ASUS RTX 4060 OC |

| Storage | Samsung 970 EVO NVMe 1Tb, Intel 665p Series M.2 2280 1TB // Samsung 1Tb SSD |

| Display(s) | ASUS VP348QGL 34" Quad HD 3440 x 1440 // 55" LG 4K SK8000 Series |

| Case | Seasonic SYNCRO Q7// Silverstone Granada GD05 |

| Audio Device(s) | Focusrite Scarlett 4i4 // HDMI to Samsung HW-R650 sound bar |

| Power Supply | Seasonic SYNCRO 750 W // CORSAIR Vengeance 650M |

| Mouse | G903 and a Master Mouse MM710/No mouse, MS game copntroller |

| Keyboard | EVGA / Logitech K400 |

| Software | Windows 11 Pro // Windows 10 Pro |

I realize there is more than one right way. I like the cross my self

eidairaman1

The Exiled Airman

- Joined

- Jul 2, 2007

- Messages

- 44,291 (6.80/day)

- Location

- Republic of Texas (True Patriot)

| System Name | PCGOD |

|---|---|

| Processor | AMD FX 8350@ 5.0GHz |

| Motherboard | Asus TUF 990FX Sabertooth R2 2901 Bios |

| Cooling | Scythe Ashura, 2×BitFenix 230mm Spectre Pro LED (Blue,Green), 2x BitFenix 140mm Spectre Pro LED |

| Memory | 16 GB Gskill Ripjaws X 2133 (2400 OC, 10-10-12-20-20, 1T, 1.65V) |

| Video Card(s) | AMD Radeon 290 Sapphire Vapor-X |

| Storage | Samsung 840 Pro 256GB, WD Velociraptor 1TB |

| Display(s) | NEC Multisync LCD 1700V (Display Port Adapter) |

| Case | AeroCool Xpredator Evil Blue Edition |

| Audio Device(s) | Creative Labs Sound Blaster ZxR |

| Power Supply | Seasonic 1250 XM2 Series (XP3) |

| Mouse | Roccat Kone XTD |

| Keyboard | Roccat Ryos MK Pro |

| Software | Windows 7 Pro 64 |

I realize there is more than one right way. I like the cross my self

The video proved it. I tried the dot and went right back to spread.