A guide to the information you should look at to find cases on the TAKACHI website.

As a side note, the display would not fit into a case that was one size smaller than the PF24-4-24W.

Please see the model number list for

NETWORK PLASTIC BOX - PF series.

The model number 24-4-24 represents the external dimensions of the case: 240mm x 40mm x 240mm.The usable internal dimensions are 187.6mm x 29.5mm x 229.5mm.It's better to read these dimensions as

229.5mm x 29.5mm x 187.6mm, since you'll probably want to use it in landscape mode.The display dimensions were 195.5mm x 11.4 x 120.8mm, so you can see that it will fit in the case.You'll notice that unlike the cases you've been building so far, there's space around the perimeter to place components without having to stack them on top of the display.

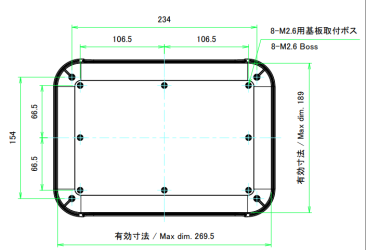

And the thing you really need to check is the Recommended PCB dimension on page 3 of the PDF drawings for each case.

*Do not make the mistake of looking at page 4. The dimensions on page 4 are for the lid (bottom of the case), which is slightly larger than the ones on page 3. If you stack them all together to an inner height of 29.5 mm using the dimensions on page 4, they will not fit into the case.

If you look at the Recommended PCB dimensions you will see that it is a cross shape.This is the true maximum size of the components that can fit into the case.The effective internal dimensions just show the largest rectangle within the Recommended PCB dimensions.

Place the component within the recommended PCB dimensions.

The effective internal height of the case is 29.5mm, but this is reduced by the height of the screw mounting studs inside the case that you will probably not use.

If you cut off the 5mm high studs on both sides with pliers or something, the height inside the case will be 39.5mm.

This is a rough example of placement by me and is by no means accurate.

If you look at the outside of the case, it looks like this:

; for sure both are needed.

; for sure both are needed. .

.