JustAguest

New Member

- Joined

- May 21, 2020

- Messages

- 3 (0.00/day)

Hi,

I was trying to re-paste my Asus ROG GL553V and I couldn't take the last screw out, I tried all the bits available in my kit, nothing really worked.

It's in a very sensitive place above the motherboard and the GPU, any help would be appreciated.

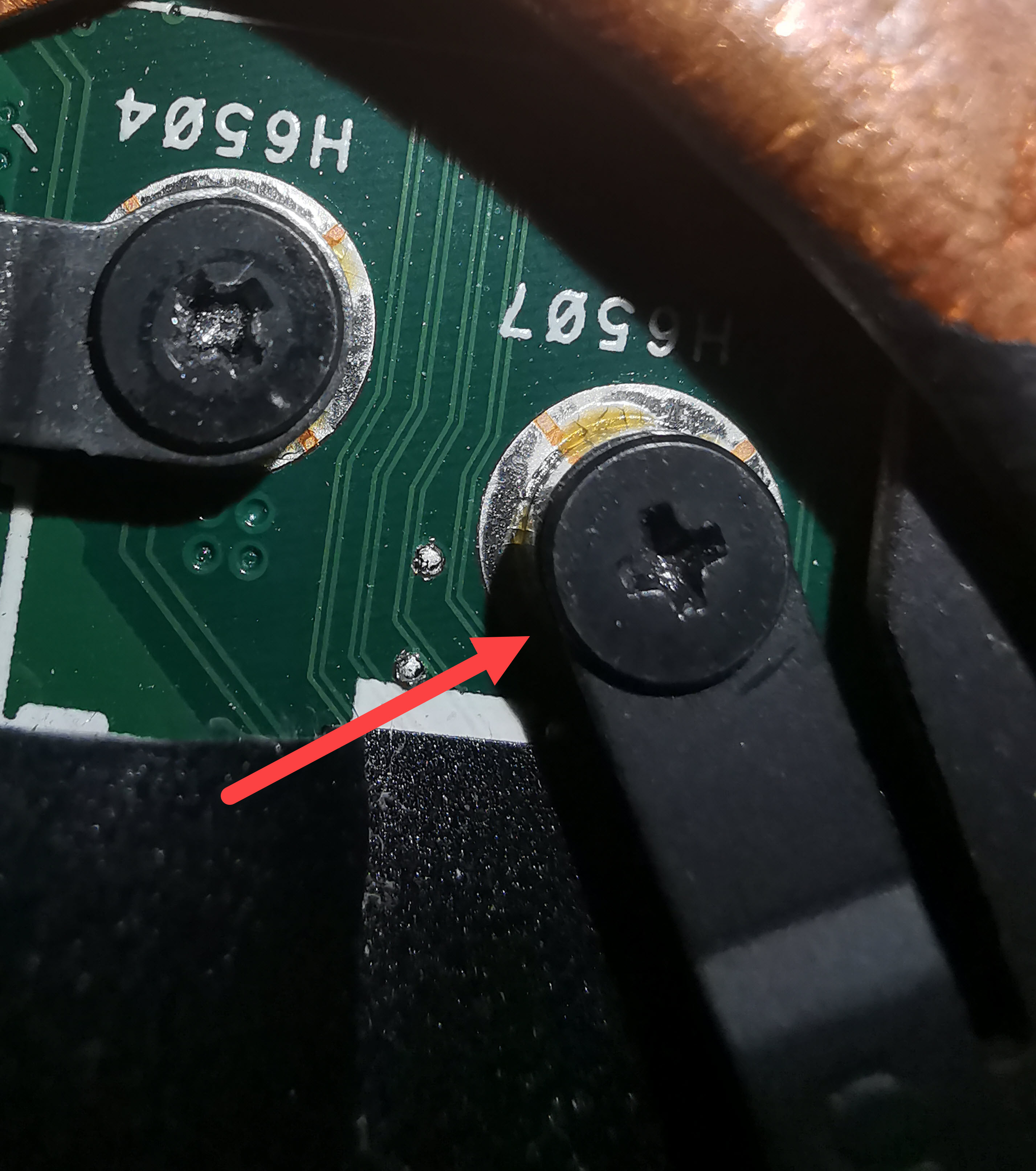

Before:

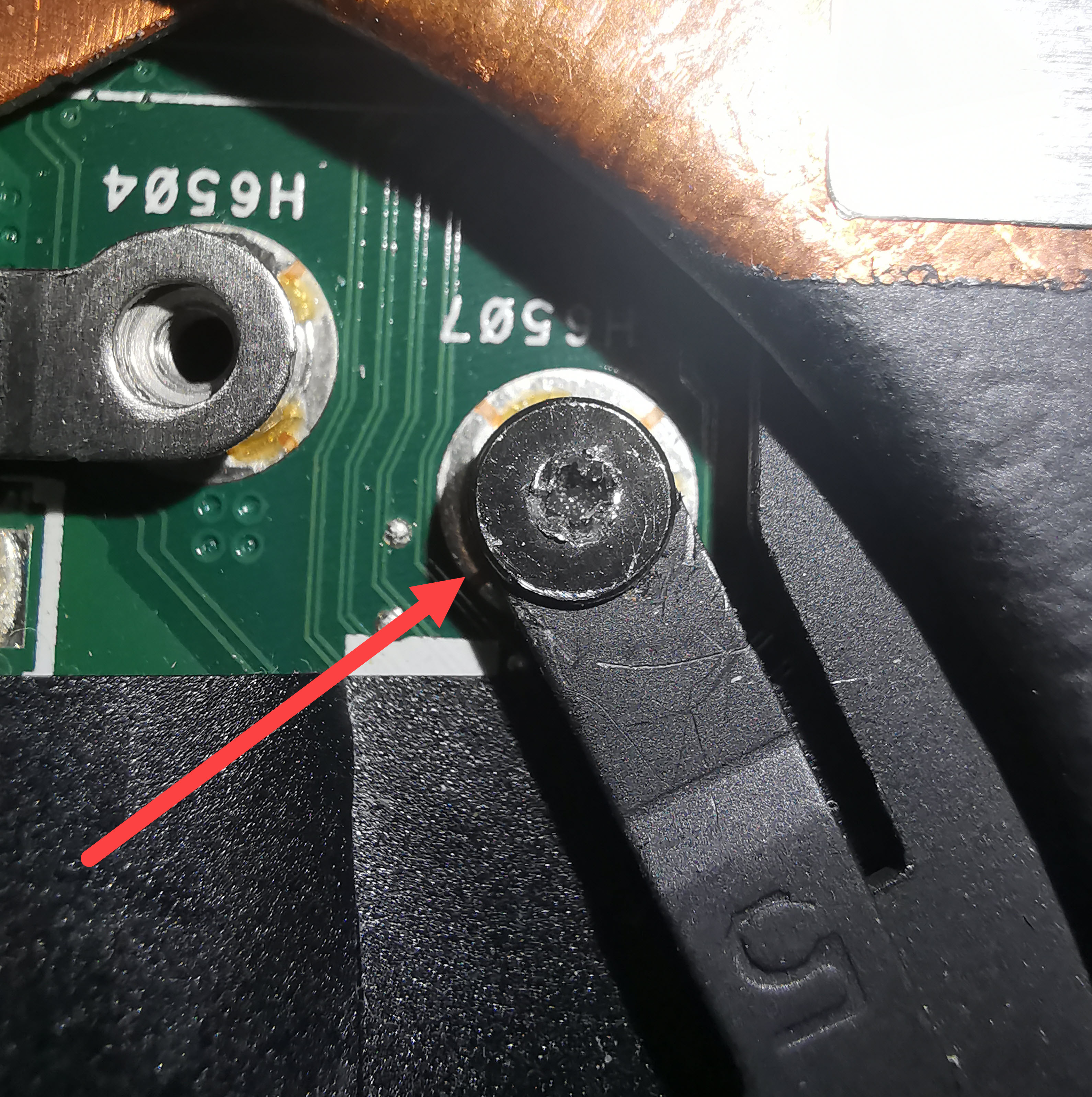

After:

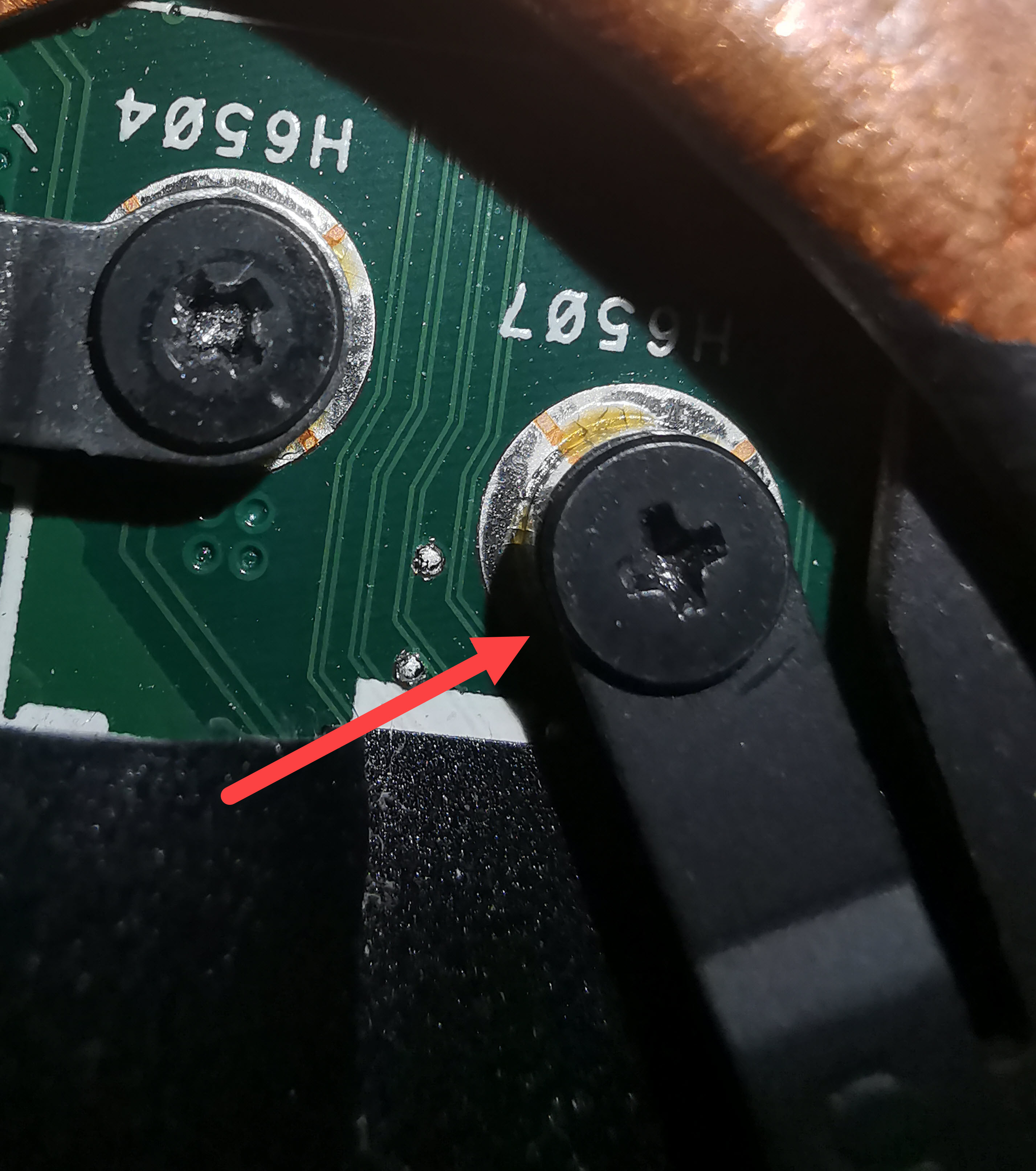

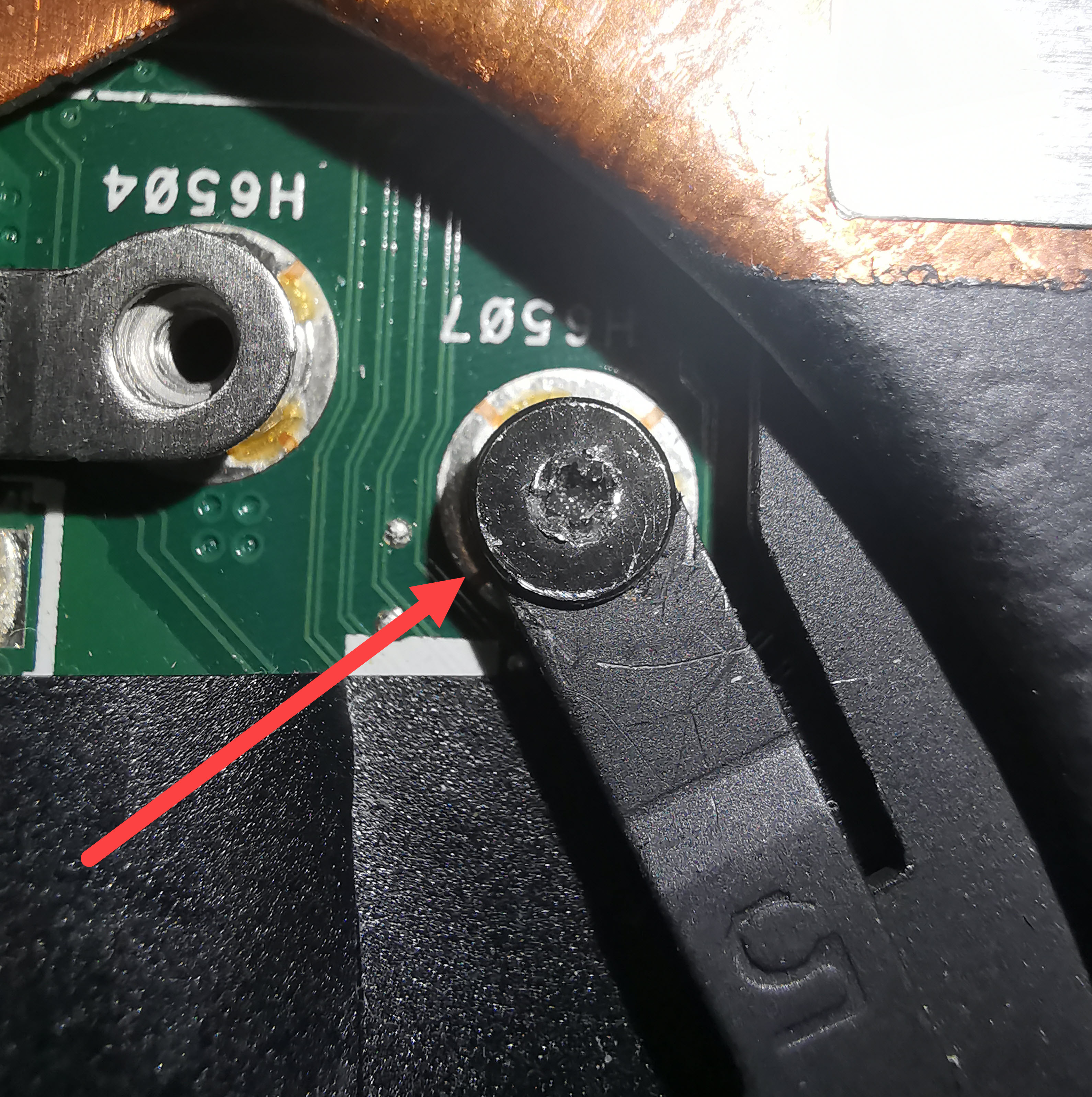

Original screw location:

P.S.: I tried super glue for about 10 minutes, didn't really work.

I was trying to re-paste my Asus ROG GL553V and I couldn't take the last screw out, I tried all the bits available in my kit, nothing really worked.

It's in a very sensitive place above the motherboard and the GPU, any help would be appreciated.

Before:

After:

Original screw location:

P.S.: I tried super glue for about 10 minutes, didn't really work.