6

6

Alphacool Eisblock ES Acetal RTX 3080/3090 Reference Review

Installation »Closer Examination

We saw before that Alphacool joins CORSAIR in throwing in a backplate with the GPU block, and it is a decent aluminium backplate at that. It comes CNC machined with an Alphacool logo on the bottom-right corner as seen from the front, as well as an acrylic inlay borrowing design cues from the block itself, I imagine. Turning things around, we see it is quite bare in that there are no machined contact surfaces to indicate where the thermal pads will be, with Alphacool instead going with an uninterrupted plane aside from the four screw mounting holes.

As with any other vendor today, Alphacool has seen the demand for RGB lighting and acrylic GPU blocks. As such, the majority of the company's GPU block SKUs in 2021 are of the Eisblock GPX Aurora variant. I was glad thus to see the RTX 3080/3090 reference PCB not only getting support for RGB, but also a more industrial look with the Eisblock ES Acetal. You get a thick acetal top that is held in place by 21 hex screws in a countersunk fashion. That helps maintain a clean look, but some no doubt will be irked by the use of the silver rather than black finish for the screws. It is otherwise a box in all the good ways, with an otherwise minimalist design that does end up looking different from the rest. Branding comes in the form of an Alphacool logo on the bottom-right corner.

Two BSP G1/4" threaded ports are part of an I/O terminal here, and on the side. This was a deliberate choice many will no doubt find interesting since it potentially allows for some neater tubing routes in your DIY loop. There have been some such implementations for GPU blocks using the NVIDIA RTX 3080/3090 Founders Edition PCB, so it was good to see Alphacool use it here to further distinguish the Eisblock ES Acetal from competing solutions. Arrows etched into the top indicate the preferred inlet and outlet port, and the disadvantage of this implementation is that we only have two ports rather than the usual four. Of note is also that the two ports are now so close to each other that you have to choose fittings accordingly. You may use up to 13/16 mm barb or compression fittings, but are forced to go down to 9/13 mm angled fittings to avoid any issues. The provided tool and low-profile stop plugs are redundant here thus, even if they do look nice, being flush with the threads.

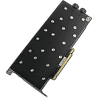

Turning the block around, we see an interesting implementation of the cold plate. Reference vs. Founders edition PCB differences threw all GPU block makers a curve ball, and then the use of taller-than-expected capacitors made things worse. What Alphacool has done is to use three separate contact plates rather than a single larger one. These are all nickel-plated copper and get a mirror polish that makes the photography not the easiest thing in the world. You can also see the machining marks on the acetal here, with none visible on the cold plates themselves.

As per usual, disassembly was done after all testing was complete. I began with taking the I/O terminal off, which is held in place using three screws and two O-rings. Taking the top off is more involved owing to the 21 screws here, although you don't need to remove all of them if you only want a look at the central cold plate. If you do take them all off, you will see that the acetal top is actually a two-piece unit. It ends up more like a distribution plate thus, with carved channels to allow coolant to flow from one cold plate to another. There are multiple parallel splits, too, which bodes well for lower coolant flow restriction.

Here is a closer look at the three pieces that make up the eventual cold plate, which really are three separate cold plates. O-rings in all three ensure the coolant only flows through the appropriate channels. The finish on the nickel plating could be improved, especially on the smaller plates where you can see some exposed copper. This does not impact the loop itself since it is all outside of the coolant pathway, but still does not look good.

The central piece is larger and more circular, which is interesting since it not only caters to the GPU core but also the VRAM around it. Why not go with a rectangular piece to allow for more coolant flow and a larger surface area with the VRAM? I suppose time will tell, but at least the GPU core section is as expected with a jetplate to allow for split central-inlet flow. With 22 microfins and 23 microchannels, there is increased surface area for heat dissipation from the GPU core. I will also note that the cold plate is thinner than previous-generation Alphacool blocks, coming in at 5.5 mm compared to the previous ~7 mm. This is coupled with slightly thinner thermal pads relative to previous Alphacool block thermal pads and means the critical components to be cooled are closer to the coolant than before, which further improves heat transfer.

Aug 2nd, 2025 05:09 CDT

change timezone

Latest GPU Drivers

New Forum Posts

- memory used for store firmware in adapters wifi usb (6)

- Weird issue with Worms: Armageddon on NV GPUs (11)

- Question about Intel Optane SSDs (91)

- Windows 12 (245)

- My UPS keep sending alarm when I game (39)

- What are you playing? (24030)

- What's your latest tech purchase? (24429)

- HELP (0)

- Free Games Thread (4838)

- 3DMARK "LEGENDARY" (359)

Popular Reviews

- ASUS ROG Crosshair X870E Apex Review

- MSI Claw 8 AI+ A2VM Review

- Montech X5 Review

- Orbital Pathfinder Review

- Herman Miller Logitech G Embody Review - No Pain, No Gain

- Lenovo Legion 5i (15IRX10) Review - Feature-Rich and Wallet Friendly

- Lian Li HydroShift II LCD-C 360TL Review

- Upcoming Hardware Launches 2025 (Updated May 2025)

- Noctua NF-A12x25 G2 PWM Fan Review

- Lian Li O11 Dynamic Mini V2 Review

TPU on YouTube

Controversial News Posts

- AMD's Upcoming UDNA / RDNA 5 GPU Could Feature 96 CUs and 384-bit Memory Bus (138)

- AMD Radeon RX 9070 XT Gains 9% Performance at 1440p with Latest Driver, Beats RTX 5070 Ti (131)

- Intel "Nova Lake-S" Core Ultra 3, Ultra 5, Ultra 7, and Ultra 9 Core Configurations Surface (110)

- DDR6 Memory Arrives in 2027 with 8,800-17,600 MT/s Speeds (102)

- NVIDIA to Debut GeForce RTX 50-series SUPER GPUs by Christmas (101)

- AMD Sampling Next-Gen Ryzen Desktop "Medusa Ridge," Sees Incremental IPC Upgrade, New cIOD (97)

- Intel CEO Confirms SMT To Return to Future CPUs (95)

- NVIDIA Becomes First Company Ever to Hit $4 Trillion Market-Cap (94)