Thursday, March 5th 2020

In Win Intros SR24 AIO CPU Cooler with Twin Turbine Pump

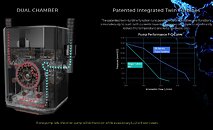

In Win today rolled out the SR24, an all-in-one liquid CPU cooler featuring a patented "twin turbine pump" feature. These are basically two pump turbines attached on both ends of the DC motor's shaft, which in turn are located on either ends of the CPU block. One of the turbine pushes coolant into the block, while the other pulls heated coolant from it. In Win claims that even if one of the two fails over time, the other will provide sufficient coolant pressure to cool your CPU, while a warning LED lights up. With both turbines operational, the SR24 offers double the coolant pressure, and a markedly superior P-Q curve. The pump block is capped off with an RGB illuminated In Win logo.

The innovative pump-block of the In Win SR24 is tubed to a 240 mm x 120 mm aluminium radiator. Ventilating it are a pair of included In Win Jupiter 120 mm fans that each spin at speeds of 500 to 2,500 RPM, with up to 101.5 CFM of air-flow, and as low as 23 dBA of noise output. The fans feature double ball bearings and feature addressable RGB LEDs in their hubs. A single 3-pin ARGB connection handles lighting for the two fans and the pump-block. The company didn't mention thermal load numbers, but among the CPU socket types supported are TR4, sTRX4, LGA2066, AM4, and LGA115x. The company didn't reveal pricing.

The innovative pump-block of the In Win SR24 is tubed to a 240 mm x 120 mm aluminium radiator. Ventilating it are a pair of included In Win Jupiter 120 mm fans that each spin at speeds of 500 to 2,500 RPM, with up to 101.5 CFM of air-flow, and as low as 23 dBA of noise output. The fans feature double ball bearings and feature addressable RGB LEDs in their hubs. A single 3-pin ARGB connection handles lighting for the two fans and the pump-block. The company didn't mention thermal load numbers, but among the CPU socket types supported are TR4, sTRX4, LGA2066, AM4, and LGA115x. The company didn't reveal pricing.

20 Comments on In Win Intros SR24 AIO CPU Cooler with Twin Turbine Pump

As both rotors are tied to the same shaft, the same motor, the chances of only one 'pump' or side failing is stupidly small. If the rotor breaks apart, you'll likely have a catastrophic failure as the bits plug the system.

Though the gains from running push-pull are well documented. It's actually how I tend to arrange the pumps in my loops. One pushes from the reservoir into the components, the other pulls from the components and pushes into the radiators, feeding back into the first pump.

I guess a simpler comparison is fan orientation on radiators. Push-pull gets a decent bump in performance compared to push only.

Aesthetically not very pleasant but the target here is the performance and i would prefer to see it with a bigger radiator to really make difference compared other AIO's.

I would seriously wonder about the efficacy of such a setup in a low-resistance system like a single-rad, single-block AIO, though.

1. If one rotor jams, how does the shaft continue to rotate ? If the rotor shears off the shaft, it leaves the stationary rotor inn the flow path which will cause a significant flow restriction.

2. Double the coolant pressure ? Compared to what ? If Corsair claimed that it's new CLC proviuded double the water flow ... as they are now 0.11 gpm, double would mean 0.22. still inadequate for a properly designed coolant system. A dr would deliver 1.0 gpm +

3. Markedly superior curver ? Again, compared to what ? In an electric car, is two 50 HP motors better than a 200 HP motor ?

4. Aluminum radiator ? Well at least it provides a science project, you can do "galvanic corrosion" for your school science fair.

5. 2500 rpm is quite noisy, not choice really with aluminum rads. Leaves it a bit weak on the low speed control

Daily reminder not to buy a AIO

The wear point is still the bearings, expect similar life span, you might see a few days of extra life on the one pump.

I am excited to see one of these torn down.

BTW I'll really miss engine sounds when EVs take over.