t_ski

Former Staff

- Joined

- Apr 11, 2006

- Messages

- 11,941 (1.71/day)

| System Name | My i7 Beast |

|---|---|

| Processor | Intel Core i7 6800K |

| Motherboard | Asus X99-A II |

| Cooling | Nickel-plated EK Supremacy EVO, D5 with XSPC Bayres & BIX Quad Radiator |

| Memory | 4 x 8GB EVGA SuperSC DDR4-3200 |

| Video Card(s) | EVGA 1080 SuperClocked |

| Storage | Samsung 950 Pro 256GB m.2 SSD + 480GB Sandisk storage SSD |

| Display(s) | Three Asus 24" VW246H LCD's |

| Case | Silverstone TJ07 |

| Audio Device(s) | Onboard |

| Power Supply | Corsair AX1200 |

| Keyboard | Corsair K95 |

| Software | Windows 10 x64 Pro |

Using the system in my sig:

Intel i7 3930K

Asus P9X79 Pro

4 x 8GB Corsair Dominator GT

Triple 7970's (stock coolers)

Triple Asus VW246H LCD's

2 x 120 GB Corsair Force 3 (Raid 0)

500GB WD

Lite-On BluRay

Nickel-plated Heatkiller 3.0 CU

D5 with EK X-top

BIX Quad Rad w/ six Noctua NF-F12 PWM fans on the rad at full speed (4 on one side, 2 on the other to fit around the PSU, which also pulls air through the rad)

BIX 120mm rad w/ one Yate Loon medium speed fan at full speed

Corsair AX1200

Silverstone TJ07

Before

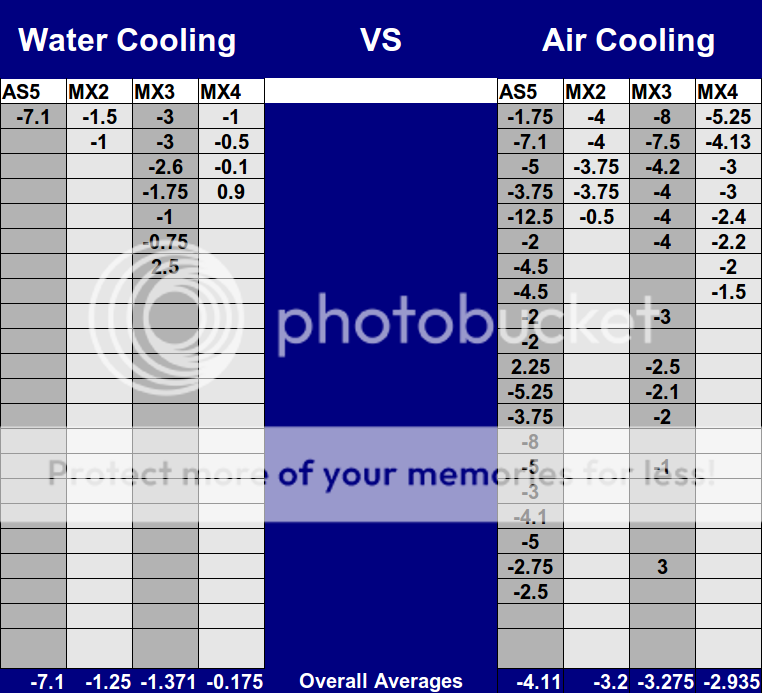

Using MX-4 thermal paste. Temps below were after a 5-pass run of Intel Burn Test.

Ambient temps were 21.3C (measured with my laser thermometer at a random, non-heat-producing item in the room). Loop temps were about 24C, measured at the res.

AFTER

Using ICD24 thermal paste. Temps below were after a 5-pass run of Intel Burn Test.

Ambient temps were 20.4C (measured with my laser thermometer at a random, non-heat-producing item in the room). Loop temps were about 23C, measured at the res.

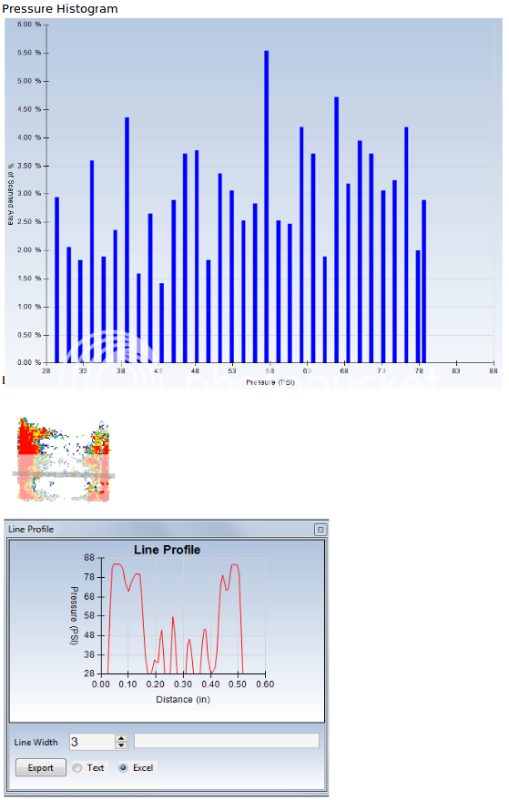

Note the hole in the IHS is at the top left corner of the paper, just as it is on the chip in the socket.

CONCLUSION

Temps were about the same given the test for ICD24 was with 1C cooler room and loop temp. In some cases, the ICD24 was just a hair warmer.

Intel i7 3930K

Asus P9X79 Pro

4 x 8GB Corsair Dominator GT

Triple 7970's (stock coolers)

Triple Asus VW246H LCD's

2 x 120 GB Corsair Force 3 (Raid 0)

500GB WD

Lite-On BluRay

Nickel-plated Heatkiller 3.0 CU

D5 with EK X-top

BIX Quad Rad w/ six Noctua NF-F12 PWM fans on the rad at full speed (4 on one side, 2 on the other to fit around the PSU, which also pulls air through the rad)

BIX 120mm rad w/ one Yate Loon medium speed fan at full speed

Corsair AX1200

Silverstone TJ07

Before

Using MX-4 thermal paste. Temps below were after a 5-pass run of Intel Burn Test.

Ambient temps were 21.3C (measured with my laser thermometer at a random, non-heat-producing item in the room). Loop temps were about 24C, measured at the res.

AFTER

Using ICD24 thermal paste. Temps below were after a 5-pass run of Intel Burn Test.

Ambient temps were 20.4C (measured with my laser thermometer at a random, non-heat-producing item in the room). Loop temps were about 23C, measured at the res.

Note the hole in the IHS is at the top left corner of the paper, just as it is on the chip in the socket.

CONCLUSION

Temps were about the same given the test for ICD24 was with 1C cooler room and loop temp. In some cases, the ICD24 was just a hair warmer.