GLOBALFOUNDRIES Ceases Operations in its Chengdu Fab

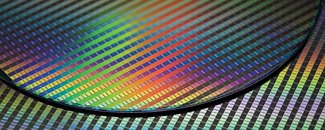

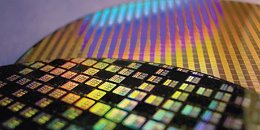

GLOBALFOUNDRIES ceased all operations in its joint-venture fab in Chengdu, China. The fab opened its doors in 2018, and was supposed to mass-produce 300 mm wafers on the 22FDX technology in a 65,000 square meter facility. The company's Chinese partner, the Chengdu Municipality, had at the time boasted of investments into the fab peaking at $10 billion. The two had also announced $2 billion in initial design wins.

GloFo's announcement to cease operations and possibly withdraw from Chengdu comes hot on the heals of a separate announcement bolstering its mainland US based facilities up to US-DoD specs for secure manufacturing, a sign that the company will scale up investment into US-based facilities. GloFo's foreshadowed withdrawal from manufacturing in China is part of the ongoing "tech war" between the US and China, with the US getting American (and West-aligned) tech companies to pull manufacturing out of China, the biggest casualties of which is Huawei.

GloFo's announcement to cease operations and possibly withdraw from Chengdu comes hot on the heals of a separate announcement bolstering its mainland US based facilities up to US-DoD specs for secure manufacturing, a sign that the company will scale up investment into US-based facilities. GloFo's foreshadowed withdrawal from manufacturing in China is part of the ongoing "tech war" between the US and China, with the US getting American (and West-aligned) tech companies to pull manufacturing out of China, the biggest casualties of which is Huawei.