Samsung's 5 nm EUV Node Struggles with Yields

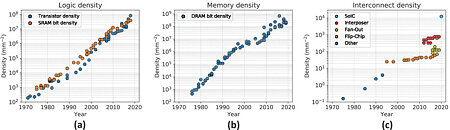

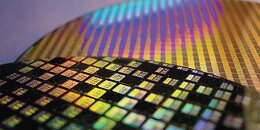

Semiconductor manufacturing is a difficult process. Often when a new node is being developed, there are new materials introduced that may cause some yield issues. Or perhaps with 7 nm and below nodes, they are quite difficult to manufacture due to their size, as the transistor can get damaged by the smallest impurity in silicon. So manufacturers have to be extra careful and must spend more time on the development of new nodes. According to industry sources over at DigiTimes, we have information that Samsung is struggling with its 5 nm EUV node.

This unfortunate news comes after the industry sources of DigiTimes reported that Qualcomm's next-generation 5G chipsets could be affected if Samsung doesn't improve its yields. While there are no specific pieces of information on what is the main cause of bad yields, there could be a plethora of reasons. From anything related to manufacturing equipment to silicon impurities. We don't know yet. We hope that Samsung can sort out these issues in time, so Qualcomm wouldn't need to reserve its orders at rival foundries and port the design to a new process.

This unfortunate news comes after the industry sources of DigiTimes reported that Qualcomm's next-generation 5G chipsets could be affected if Samsung doesn't improve its yields. While there are no specific pieces of information on what is the main cause of bad yields, there could be a plethora of reasons. From anything related to manufacturing equipment to silicon impurities. We don't know yet. We hope that Samsung can sort out these issues in time, so Qualcomm wouldn't need to reserve its orders at rival foundries and port the design to a new process.