Tuesday, April 24th 2018

Pro Overclocker der8auer Delids the AMD Ryzen 5 2600 Processor

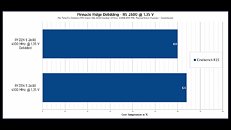

In his latest Youtube video, famous overclocker der8auer has delidded his AMD Ryzen 5 2600 processor for the sole purpose of evaluating whether the benefits justify the risk. Since the IHS in the new Pinnacle Ridge processors is soldered directly to the die with Indium, delidding the processors is a tricky but not impossible task. Everything melts when it gets warm enough, and indium starts melting around 156.60 °C. Therefore, der8auer had to use a modified version of his popular Delid Die Mate 2 tool by replacing the acrylic pieces with aluminum while also removing the rubber washer. After baking his Ryzen 5 2600 chip in the oven between 170 °C to 180 °C, Der8auer removed the IHS easily with his delidding tool. For his testing, he replaced the indium solder with Thermal Grizzly liquid metal thermal compound. As expected, the results weren't very impressive. With the Ryzen 5 2600 overclocked to 4.1 GHz with 1.35V, the difference was a mere 4 °C under load. So, there you have it. Don't delid your Pinnacle Ridge processor. It's not worth the effort.

Source:

der8auer's Youtube

27 Comments on Pro Overclocker der8auer Delids the AMD Ryzen 5 2600 Processor

Next-up, dies soldered to heatsinks.

NH-D15, step forward please.

AMD however have full clearance around the socket for the heatsink. The only issue would be proper mounting pressure on the die itself and the retention system used by the heatsink manufacturer.

Can't speak for Ryzen specifically though.

I can make my mobo board flex if i tighten the hsf screws too much, did it upon initial setup, backed them off till board no longer flexed before putting board in case

If it was just a test or experiment to see if lower temps could be had then fair beans. I guess people have their answer now.

Intel CPUs have been delidded and replacing TIM yielded no better results, so that TIM does its job as well enough. But haters will keep on doing their thing...

I have a pair of i7-7700K CPUs that didn't until I did a DeLid on them. Now I'm seeing a 15-20C lower temp on both of them. I'm using liquid metal between the lid and the silicone.

I then did my i9-7900X CPU and got vast temp reductions with it. It was throttling from high heat, but now, not so often.

DeLids, done right are a good thing with Intel CPUs these days.

Had to delid my 7700K to have decent temps for all around use, didn't have this issue with any of my AMD's.

This is a HUGE risk for VERY little, but good for him to show us it can be done,... but DONT do it, well do it if you want 4*c.... HOnestly would love to see the temp change with a higher OC, 4.1Ghz just seems low for that amount of effort?Delidded with LM my Intel CPU, it is a MUST, I run 5Ghz at or below 60c, on a custom loop. without a delid that would be remotely possible.

Signature below.